Leave Your Message

The demand for environmentally friendly materials in various industrial applications has led to the rise of Green Silicon Carbide as a vital player in the market. Green Silicon Carbide is a high-performance abrasive and semiconductor material known for its excellent hardness and thermal conductivity. According to a report by MarketsandMarkets, the global silicon carbide market is projected to reach USD 3.38 billion by 2025, expanding at a compound annual growth rate (CAGR) of 16.5% during the forecast period. This growth is significantly driven by the increasing use of Green Silicon Carbide in sectors such as electronics, automotive, and renewable energy.

In addition to its performance advantages, Green Silicon Carbide offers a range of benefits that make it an attractive option for industries striving for sustainability. With its chemical stability, low thermal expansion, and resistance to mechanical stress, Green Silicon Carbide contributes to increased durability and efficiency in applications such as cutting, grinding, and polishing. Furthermore, its ability to be produced from recycled materials aligns with global efforts toward reducing waste and promoting circular economy practices. As industries increasingly seek to minimize their environmental footprint, the incorporation of Green Silicon Carbide stands as a testament to the potential of innovative materials in shaping a sustainable future.

Green silicon carbide (SiC) is increasingly recognized for its superior performance in abrasives and grinding tools, owing to its unique properties such as high hardness, thermal conductivity, and chemical stability. As reported in a recent industry analysis, the global market for abrasives is projected to reach approximately $50 billion by 2026, with green silicon carbide contributing significantly due to its exceptional grinding capabilities. Specifically, its use in cutting, polishing, and finishing applications offers enhanced efficiency and durability compared to traditional abrasives.

In grinding tools, green silicon carbide demonstrates remarkable advantages in terms of precision and surface finish quality. Its ability to effectively cut through hard materials like metals and ceramics makes it an essential component in industries such as automotive, aerospace, and electronics. According to research from the Abrasive Association, SiC accounts for over 30% of the market share in high-performance grinding applications. Furthermore, green silicon carbide's eco-friendly production process aligns with the growing demand for sustainable materials, making it a preferred choice in environmentally conscious manufacturing practices. The ongoing development in the methodologies for producing high-purity green silicon carbide is set to further propel its adoption across various industrial sectors.

| Application | Industry | Benefits |

|---|---|---|

| Abrasive Powders | Manufacturing | High cutting efficiency and durability |

| Grinding Wheels | Metalworking | Excellent hardness and resistance to wear |

| Coated Abrasives | Automotive | Versatile use with enhanced surface finish |

| Lapping Compounds | Electronics | Achieves precise tolerances |

| Ceramics | Construction | Improves thermal stability and strength |

| Semiconductor Manufacturing | Electronics | Enhances electrical properties |

Green silicon carbide (SiC) has been gaining significant traction in the electronics industry due to its unique properties, such as high thermal conductivity, exceptional hardness, and remarkable electrical conductivity. This makes it an ideal material for a variety of electronic applications, including power devices, semiconductors, and high-performance transistors. The use of green silicon carbide in these components not only enhances their efficiency but also contributes to the miniaturization of electronic devices, paving the way for more compact and powerful gadgets.

Tips: When considering the integration of green silicon carbide into electronic components, it's essential to assess the specific thermal and electrical performance requirements of your application. Choosing the right grade of silicon carbide can optimize device reliability and efficiency.

Furthermore, green silicon carbide presents an environmentally friendly alternative to traditional materials. Its production process is less energy-intensive and generates fewer carbon emissions, aligning with the industry's shift towards sustainable manufacturing practices. By leveraging green silicon carbide, manufacturers can improve their ecological footprint while delivering high-performance electronics to consumers.

Tips: Always prioritize suppliers who demonstrate sustainable practices in the sourcing of materials, as this not only supports environmental health but can also enhance the reputation of your products in a competitive market.

Green silicon carbide (SiC) has emerged as a vital material in metal and ceramic manufacturing, owing to its superior hardness and thermal conductivity. It is particularly beneficial in grinding applications, where it excels in producing a fine finish on metals and ceramics. Manufacturers appreciate its ability to withstand high temperatures and maintain structural integrity, making it an ideal choice for high-performance tools. Additionally, green silicon carbide's lower environmental impact during production aligns it with the increasing demand for sustainable manufacturing practices.

**Tips:** When selecting green silicon carbide for your manufacturing processes, consider the specific application requirements such as the material type and desired finish. Proper integration of SiC can enhance efficiency and product quality significantly.

Furthermore, the versatility of green silicon carbide extends to its use in sintered ceramics, enhancing strength and durability. It allows for the creation of high-density ceramic components that exhibit excellent wear resistance and thermal stability. This robustness makes it suitable for various applications, including automotive and aerospace components, where performance and reliability are crucial.

**Tips:** Always perform thorough testing when implementing green silicon carbide in new applications, as variations in composition and particle size can profoundly affect performance outcomes. Collaborating with material specialists can also optimize your formulation for specific manufacturing needs.

Green silicon carbide (SiC) is gaining prominence in various industrial applications due to its remarkable environmental benefits. One of the key advantages of using green silicon carbide lies in its production process, which is significantly more sustainable compared to other abrasive and semiconductor materials. According to a report by TechSci Research, the global green silicon carbide market was valued at approximately $1.2 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of around 8% from 2021 to 2026, driven largely by its eco-friendly manufacturing techniques. The use of recycled materials in production further enhances its sustainability profile, reducing the carbon footprint associated with manufacturing processes.

In addition to its production benefits, green silicon carbide offers superior performance characteristics that lead to lower energy consumption in various applications, such as metalworking, electronics, and energy sectors. Research from The Freedonia Group indicates that abrasives made from green silicon carbide can achieve up to 30% better performance efficiency than conventional materials, contributing to reduced resource usage. This not only minimizes waste and emissions but also aligns with global sustainability goals, making green silicon carbide a critical component in industries aiming to enhance their environmentally responsible practices. As industries increasingly pivot towards sustainable solutions, the adoption of green silicon carbide is essential for balancing high performance with environmental stewardship.

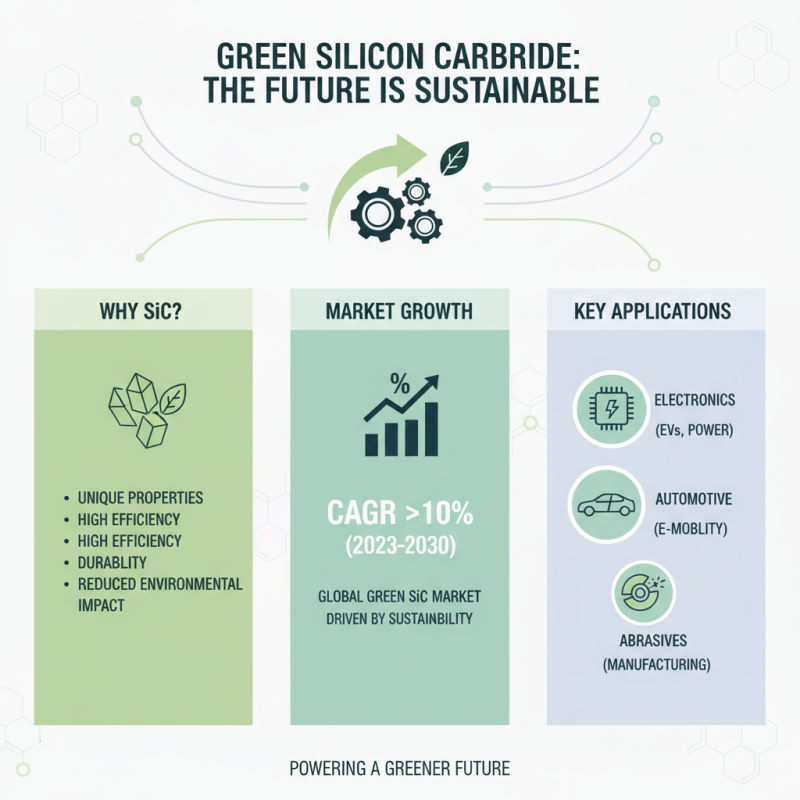

The future of green silicon carbide (SiC) applications is poised for significant advancements, driven by the material's unique properties and the growing demand for sustainable solutions across various industries. As industries shift towards green technologies, the adoption of green silicon carbide is projected to increase drastically. According to a recent market analysis, the global green silicon carbide market is expected to grow at a CAGR of over 10% from 2023 to 2030, highlighting its rising prominence in sectors such as electronics, automotive, and abrasives.

Innovations in manufacturing processes and the development of advanced green SiC products are creating new opportunities for applications in power electronics and electric vehicles (EVs). The ability of green silicon carbide to operate at high temperatures and voltages makes it an ideal candidate for energy-efficient semiconductor devices. Research suggests that by harnessing the potential of green SiC, the efficiency of power conversion systems in electric vehicles can improve by up to 30%, enhancing overall performance and extending battery life.

Moreover, as industries strive for reduced carbon footprints, the eco-friendly production processes of green silicon carbide, which utilize recycled materials, become increasingly attractive. This aligns with global sustainability goals, making green silicon carbide not just a functional material, but a cornerstone for future innovations in clean technologies, reinforcing its role in paving the way for a greener industrial landscape.