Leave Your Message

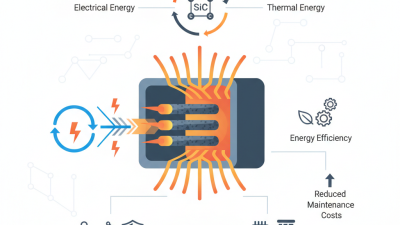

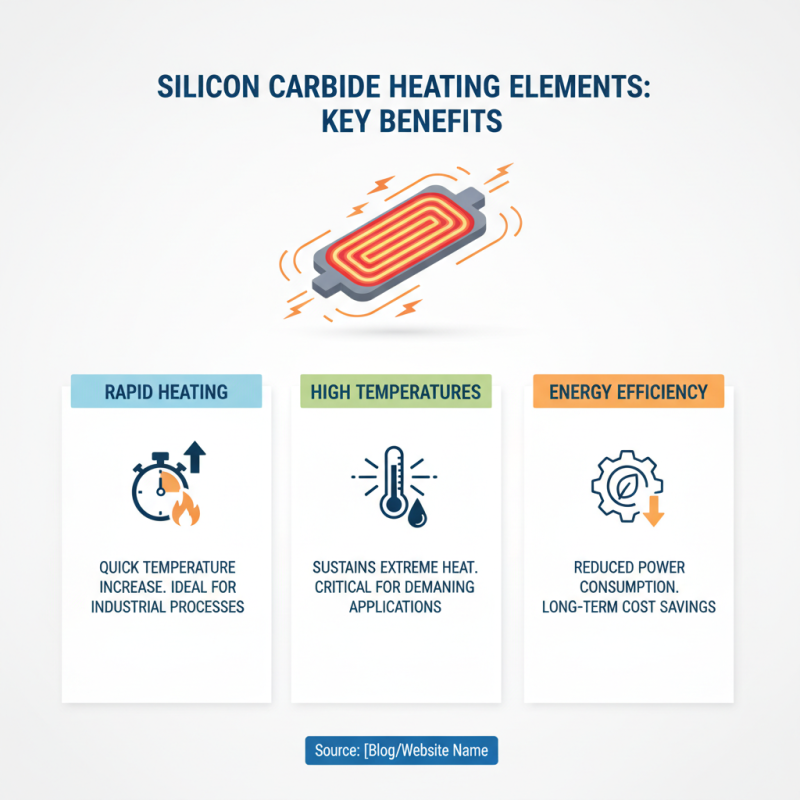

In today's industrial landscape, efficient heating solutions are vital. The choice of heating element can greatly influence performance. Among various options, the Silicon Carbide Heating Element stands out. This material offers numerous advantages, making it a popular choice in various applications.

Silicon Carbide Heating Element is known for its high thermal efficiency. It can reach elevated temperatures quickly, which enhances productivity. Moreover, it shows excellent durability, often outlasting other materials. Many industries rely on this technology for its reliability. However, users must consider that it may not suit every situation. Some applications might require alternative heating solutions.

In conclusion, exploring the best Silicon Carbide Heating Element could benefit many operations. Its strengths are impressive, yet individuals should reflect on their specific needs. Balancing efficiency with practicality can lead to better decision-making. Ultimately, the right heating choice can optimize processes and improve outcomes.

Silicon carbide (SiC) heating elements are gaining traction in various industries. They offer high thermal conductivity and exceptional durability. According to a recent market analysis, SiC heating elements can operate at temperatures up to 1600°C. This capability allows for efficient heating in applications such as sintering and metal processing.

One significant benefit of silicon carbide heating elements is their energy efficiency. Reports indicate they can reduce energy consumption by up to 30% compared to traditional heating methods. This reduction translates to substantial cost savings, especially in large-scale operations. Additionally, SiC elements have a longer lifespan, often outlasting their ceramic counterparts by two to three times.

However, the initial investment in silicon carbide technology may be a hurdle for smaller companies. While the long-term benefits are clear, upfront costs can be daunting. It is essential for businesses to weigh the implications of this investment against their operational needs. As industries evolve, embracing these advanced heating solutions could lead to greater efficiencies and sustainability in manufacturing processes.

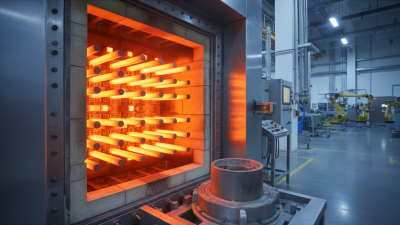

Silicon carbide heating elements are increasingly popular for industrial heating solutions. They provide efficient and high-temperature heating, making them ideal for various applications. The materials often operate at temperatures up to 1600°C. According to a recent industry report, the global market for silicon carbide heating elements is projected to grow at a CAGR of 6.5% through 2027. This growth highlights the demand for efficient heating technologies.

High-quality silicon carbide heating elements feature excellent thermal conductivity. They can work in harsh environments, resisting oxidation and thermal shock. This durability is essential for industries that require reliable performance under extreme conditions. Reports indicate a significant reduction in operational costs, benefiting industries like ceramics, steel, and glass. However, the initial investment can be high. Companies must assess the long-term benefits versus upfront costs.

Flexibility in design is another key characteristic. Many elements can be customized to fit specific applications. This customization allows for optimized heating profiles, crucial for precision manufacturing. Nevertheless, not all suppliers offer these tailored solutions. Companies might face challenges finding the right specifications. This situation underscores the importance of thorough research before making a purchase. Implementing silicon carbide heating solutions can lead to improved efficiency, but it's essential to evaluate every option carefully.

Silicon carbide (SiC) heating elements have a wide range of applications across various industries. Their high thermal conductivity and resistance to thermal shock make them ideal for demanding environments. For example, according to a 2022 market report, the global demand for SiC heating elements is projected to grow by 7.5% annually. This surge is driven by their efficiency in industrial heating processes.

In the semiconductor industry, SiC elements are increasingly used for crystal growth. They maintain stable temperatures, crucial for producing high-quality wafers. Reports suggest that using SiC in this application can increase energy efficiency by 30%. While many manufacturers adopt SiC, the transition can be challenging. The initial cost is higher compared to traditional materials, and some facilities may require retrofitting.

The aerospace sector also benefits from SiC heating elements. They can handle extreme temperatures without compromising performance. A recent study found that SiC elements can reduce heating times by 20%, increasing throughput. However, some engineers still express concerns regarding their lifespan in critical applications. Understanding these trade-offs is essential. The potential for SiC heating technology is immense, yet challenges remain.

| Application | Temperature Range (°C) | Material Compatibility | Efficiency (%) | Lifetime (Hours) |

|---|---|---|---|---|

| Industrial Furnaces | 300 - 1600 | Metals, Ceramics | 90 | 5000 |

| Semiconductor Manufacturing | 200 - 1200 | Silicon, Gallium | 95 | 6000 |

| Glass Melting | 600 - 1200 | Glass Materials | 88 | 4000 |

| Plating and Coating | 150 - 900 | Various Metals | 92 | 3000 |

When comparing silicon carbide heating elements to other heating solutions, several factors come into play. Silicon carbide offers rapid heating capabilities. This can be particularly beneficial in industrial applications. These elements maintain high temperatures efficiently. This efficiency can lead to energy savings over time.

However, silicon carbide is not without its drawbacks. They can be more expensive than traditional heating elements. Additionally, the material can be brittle, posing risks during handling. The performance of silicon carbide elements may vary based on usage. In contrast, wire or ceramic heaters might be easier to replace. They can provide adequate heating but may lack efficiency.

Another factor to consider is heat distribution. Silicon carbide provides excellent surface area for heat release. This can improve the uniformity of heating. On the flip side, some heating solutions may not distribute heat evenly. This inconsistency could lead to hot or cold spots. Therefore, assessing your specific heating needs is critical for optimal performance.

When selecting silicon carbide heating elements, several factors deserve attention. The maximum operating temperature is critical. Different applications have varying temperature needs. Choose elements that can handle your specific requirements well. Also, consider the power density. A higher power density often leads to faster heating, but excessive density may shorten the element's lifespan.

Another aspect to evaluate is the thermal conductivity. Elements with higher thermal conductivity can transfer heat more efficiently. This can lead to better overall performance in heating solutions. Pay attention to the shape and size of the elements as well. They must fit your design and requirements perfectly. Poor fitting can lead to inefficient heating and wasted energy.

Durability is important, but not all elements are created equal. Some may claim high durability but fail under certain conditions. Test and learn from past experiences, especially in high-demand environments. Regular maintenance can also extend the life of silicon carbide heating elements. However, understanding wear and tear is essential for optimal performance. Regular checks can prevent unexpected breakdowns.