Leave Your Message

In the pursuit of efficient heating solutions, the focus on Silicon Carbide Heating Elements has gained prominence. With exceptional thermal conductivity and high-temperature resistance, these elements stand out in various applications. Industries are shifting towards materials that offer durability and superior performance.

Silicon Carbide Heating Elements are not just innovative; they also demand responsible use. Their effectiveness can sometimes mask safety concerns. Overheating can occur if not monitored properly. It’s essential to ensure systems are designed with precision to prevent such risks.

As we explore the best options for 2026, it's crucial to evaluate both performance and safety. Not every product on the market meets high standards. Users must reflect on the potential for improvement and seek reliable reviews. Balancing efficiency with responsibility will be key to optimizing heating solutions in the future.

Silicon carbide heating elements are renowned for their efficiency. They excel in high-temperature applications. Their ability to withstand extreme environments sets them apart from other materials. Many industries rely on them for consistent heating solutions. These elements heat quickly, providing instant heat where needed. This is crucial for processes requiring precision heating.

Tips: Consider your application carefully. Check the maximum temperature required. Not all elements can handle the same heat. Sometimes the specifications can be misleading.

The durability of silicon carbide is impressive. These elements can last longer than alternatives. However, they may not be the best choice for all settings. Some environments might accelerate degradation. It's essential to assess the specific needs. Be aware that even small variations can impact performance significantly.

Tips: Regular maintenance can extend the lifespan of your heating elements. Ensure proper installation to prevent early failure. Don't overlook the importance of quality control during the heating process.

Silicon carbide, often known for its durability, proves advantageous for heating applications. It can withstand high temperatures without losing efficiency. This property makes it suitable for various industrial processes where reliable heating is a must. Many industries benefit from this capability, particularly those involving metalworking and ceramics.

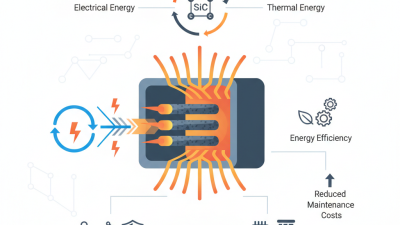

Another key advantage of silicon carbide is its excellent thermal conductivity. It allows for quick heating and even temperature distribution. As a result, it reduces energy waste during operations. However, some users may struggle with choosing the right form and size for their specific applications. It’s not always easy to find the perfect match, and experimentation may be required.

Furthermore, silicon carbide enhances energy efficiency. It can significantly lower energy bills, which is crucial for large operations. However, transitioning to silicon carbide heating elements may present challenges. Users need to consider existing equipment compatibility carefully. These factors might complicate the adoption process, leading to potential setbacks.

When selecting silicon carbide heating elements, there are key features to consider. One vital aspect is temperature stability. These elements should withstand high temperatures consistently. A range of operating temperatures can offer versatility for various applications.

Another feature is thermal efficiency. Heating elements with better heat retention can reduce energy costs. This efficiency is crucial for industries that rely on prolonged heating cycles. Additionally, material quality plays a significant role. Durable materials can enhance lifespan, reducing frequent replacements.

Safety is non-negotiable. Elements must have built-in safety features to prevent overheating. Look for elements that minimize risks through effective design. User-friendly controls are essential too. They should allow precise adjustments for varying heating requirements. While many options exist, not all will meet every need. Reflection on your specific requirements can guide an informed choice.

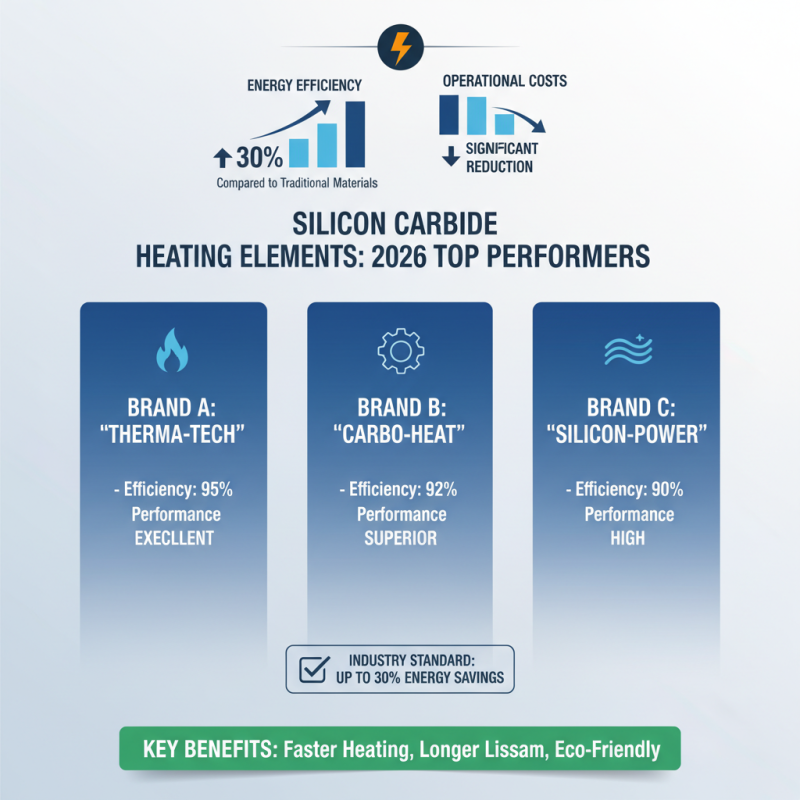

As we explore the best silicon carbide heating elements in 2026, it's essential to compare leading brands based on efficiency and performance. Recent industry reports indicate that silicon carbide heaters improve energy efficiency by up to 30% compared to traditional materials. This can significantly lower operational costs in industrial settings.

One notable area of difference among brands is the thermal conductivity. Some products achieve rates as high as 60 W/mK, enhancing heat distribution. These features result in quicker heating times, which is crucial in high-demand applications. However, some brands struggle with durability under extreme temperatures, leading to potential failures.

Another critical aspect is temperature control. Advanced silicon carbide elements offer precise temperature regulation, boasting fluctuations of less than ±5°C. Yet, not all manufacturers meet this metric, revealing a gap in performance that users must consider. This variability highlights the need for rigorous testing before choosing a heating solution.

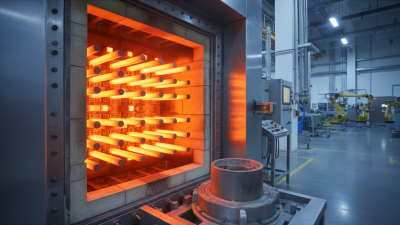

Silicon carbide heating elements are increasingly used in various industries. Their high thermal conductivity and resistance to thermal shock make them ideal for high-temperature applications. These elements serve a critical role in manufacturing processes such as ceramics and metal processing, where controlled heating is essential.

In the ceramic industry, silicon carbide elements provide uniform heating. This uniformity reduces the risk of defects in the final product. However, the initial cost can be a barrier. Not every factory can easily adopt this technology.

Another key application lies in the semiconductor industry. Silicon carbide elements help maintain precise temperature control during production. Yet, their effectiveness can be affected by the environment. Factors like humidity and dust can impact performance. It's a consideration worth reflecting on for future improvements.

| Heating Element Type | Max Temperature (°C) | Power Rating (kW) | Application | Material Composition |

|---|---|---|---|---|

| Silicon Carbide Rod | 1600 | 12 | Industrial Furnaces | 99% SiC |

| Silicon Carbide Plate | 1450 | 10 | Ceramic Industry | 98% SiC |

| Silicon Carbide Tube | 1400 | 8 | Metallurgical Processing | 95% SiC |

| Silicon Carbide Disc | 1550 | 15 | Heating Applications | 97% SiC |

| Silicon Carbide Wire | 1300 | 5 | Laboratory Heating | 96% SiC |