Leave Your Message

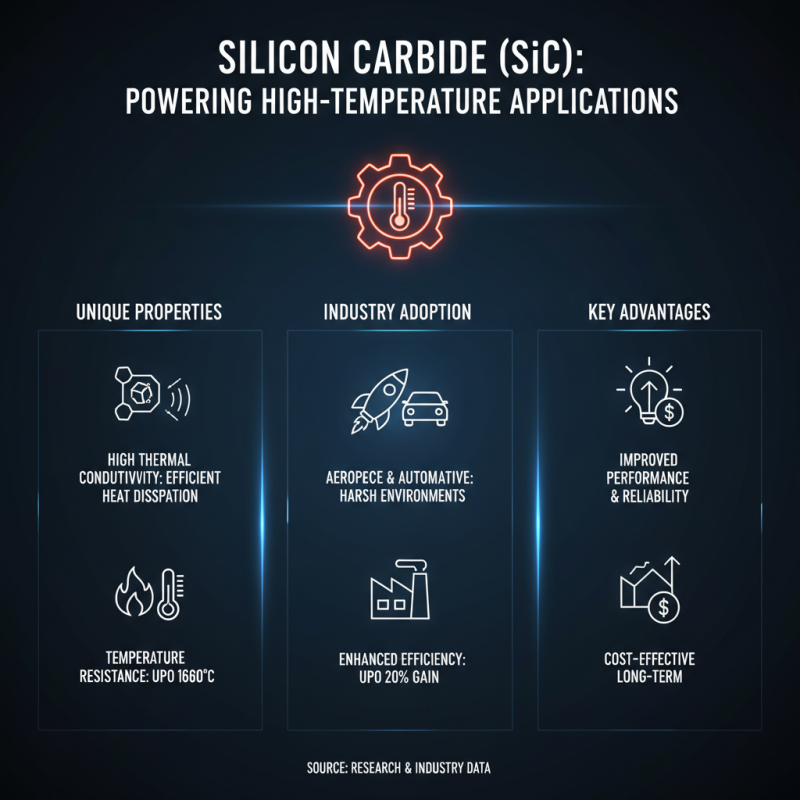

Silicon Carbide Rods have emerged as a dominant choice for high-temperature applications. Their unique properties make them suitable for extreme environments, where traditional materials often fail. According to a recent industry report by MarketsandMarkets, the global market for silicon carbide is projected to reach $3.6 billion by 2025, driven by increasing demand in various sectors, such as aerospace, automotive, and electronics.

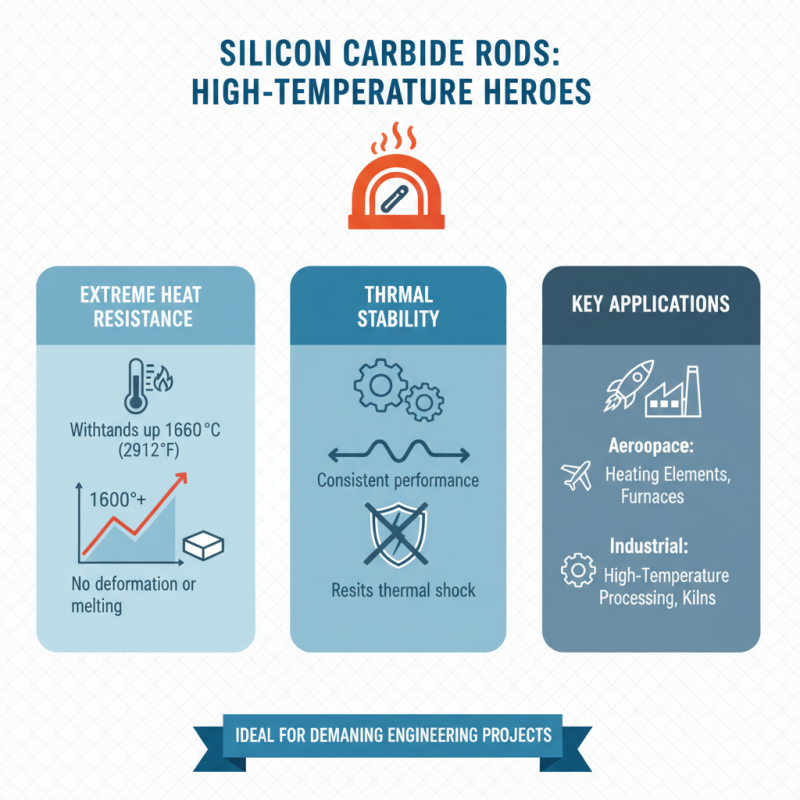

These rods exhibit exceptional thermal conductivity and mechanical strength. They can withstand temperatures exceeding 1,600°C. However, not all silicon carbide rods are created equal. Quality variations exist based on manufacturing processes, which can impact performance. It's crucial for buyers to consider these factors when selecting rods for their specific applications.

In some cases, the high costs associated with premium silicon carbide rods might deter potential users. While the investment can yield superior performance, budget constraints can lead to suboptimal choices. Careful evaluation of application requirements is essential. Ultimately, understanding the landscape of silicon carbide rods can help in making informed decisions that align with operational needs.

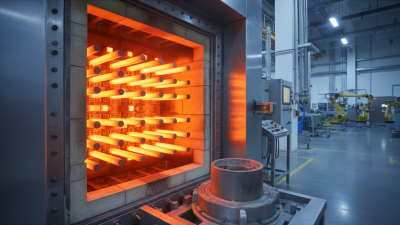

Silicon carbide rods are essential in high-temperature environments. They withstand extreme heat and offer remarkable thermal stability. In industries like aerospace, these rods find applications in heating elements and furnaces. Their ability to endure intense conditions makes them an ideal choice for many engineering projects.

These rods are not without their challenges. The manufacturing process can be inconsistent, leading to variations in quality. Proper testing is crucial to ensure reliability. Understanding the thermal conductivity and strength of silicon carbide is essential. Engineers often spend extra time analyzing their properties to avoid failures.

The versatility of silicon carbide extends to electronics and semiconductor applications. They enable efficient heat dissipation, which is vital in modern devices. However, working with silicon carbide requires expertise. A common issue is selecting the right rod for specific applications, as not all rods perform alike under varying conditions. Always consider the unique demands of your project before choosing.

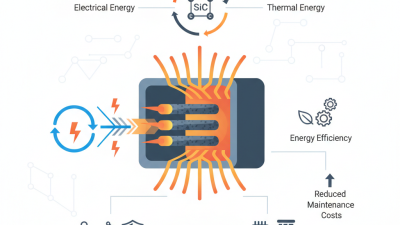

Silicon carbide (SiC) is gaining traction in high-temperature applications due to its unique properties. Its high thermal conductivity allows efficient heat dissipation. SiC can withstand temperatures up to 1,600 degrees Celsius. This capability makes it suitable for harsh environments, such as aerospace and automotive industries. Research indicates SiC components can enhance efficiency by 20% compared to traditional materials.

In addition to thermal stability, SiC exhibits excellent mechanical strength. Reports show that SiC has a tensile strength of approximately 400 MPa. This strength is crucial for maintaining structural integrity in extreme conditions. However, the brittleness of SiC may pose challenges in specific applications. Attention to design is necessary to mitigate potential failures.

Another significant aspect of SiC is its chemical resistance. It can withstand oxidation and corrosion better than many alternatives. Still, certain conditions may lead to degradation over time. Periodic evaluations are essential to ensure reliable performance. Innovations in SiC processing are ongoing, which may further enhance its utility in high-temperature environments.

Silicon carbide rods have become essential in high-temperature applications. Their ability to withstand extreme conditions makes them popular in various industries. Many sectors, including automotive and aerospace, rely heavily on these materials.

However, not all silicon carbide rods are created equal. Different types have varying properties, which can affect their performance. For instance, some rods are designed for thermal conductivity, while others focus on mechanical strength. A recent industry report indicated that rods with a higher purity level exhibit better thermal properties. In high-temperature scenarios, even small variations can lead to significant performance differences.

However, challenges remain. The production processes for silicon carbide rods can introduce inconsistencies. Some users have reported difficulties in achieving the desired uniformity. Variations in grain size and porosity can affect reliability. Data from recent studies illustrate that a rod's microstructural properties greatly influence its longevity.

Optimization of manufacturing techniques is crucial for addressing these challenges and improving the overall performance of silicon carbide rods in demanding environments.

Silicon carbide rods are crucial for high-temperature applications. Their unique properties include exceptional thermal conductivity and strength. Many manufacturers focus on these attributes to produce quality rods. The best rods withstand temperatures beyond 1400°C.

Different manufacturers utilize various techniques in their production. Sintering, for instance, helps enhance the rods' durability and reliability. Some rods are designed for specific applications, like furnaces or heating elements. Buyer reviews often reveal inconsistencies in quality, making it essential to research before purchasing.

The manufacturing process can be complex. This complexity sometimes leads to variability in product performance. Users might find that some rods fail to meet expected standards. It's important to understand that even reputable sources can have occasional flaws. Gathering feedback from industrial users can provide valuable insights.

| Product Name | Diameter (mm) | Length (mm) | Maximum Temperature (°C) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| Silicon Carbide Rod A | 10 | 300 | 1600 | 120 |

| Silicon Carbide Rod B | 12 | 400 | 1700 | 130 |

| Silicon Carbide Rod C | 8 | 250 | 1500 | 110 |

| Silicon Carbide Rod D | 15 | 500 | 1750 | 140 |

Silicon carbide rods are crucial for high-temperature applications. To maximize their benefits, proper maintenance is essential. Regular inspection of these rods can prevent significant failures. Check for signs of wear or degradation. Even minor damage may lead to poor performance. It's important to keep a close eye on rod surfaces and connections.

Tips: Always clean the rods after use. Dust and residues can alter their efficiency. Use a soft brush or compressed air to remove debris. Regular cleaning helps maintain optimal performance and extends the lifespan of silicon carbide rods.

In high-heat conditions, the operating environment can affect rod durability. Monitoring temperature fluctuations is key. Experts recommend maintaining temperatures below 1,600°C to avoid structural damage. Inconsistent heating can weaken the rods, causing premature failure. Consider using a thermal pad for even heat distribution.

Tips: Apply a silicone-based lubricant at connections. It reduces friction and minimizes wear. This small step can significantly enhance the longevity of your rods. While silicon carbide is robust, it is not invincible. Always review operational conditions and adjust maintenance accordingly.

This chart displays the maximum operating temperatures of various silicon carbide rods, which are crucial for selecting the right material for high-temperature applications. Each rod is designed to sustain different heat levels, hence their varying temperature thresholds.