Leave Your Message

In recent years, the demand for efficient energy solutions has surged. Analysts project that the Silicon Carbide Semiconductor market will grow at a CAGR of 30.3% from 2021 to 2028. This remarkable growth is attributed to the increasing adoption of electric vehicles and renewable energy sources. Silicon Carbide, or SiC, excels in high-voltage and high-temperature applications. Its efficiency is critical for modern power electronics.

Performance metrics show that SiC devices offer lower conduction losses. For example, they can operate at much higher temperatures than traditional silicon devices. This allows for smaller, lighter designs which enhance overall system efficiency. However, challenges remain. The manufacturing process for Silicon Carbide can be complex and costly. There's still a need to improve yield rates and reduce production costs.

Market players must reflect on these challenges. As SiC technology evolves, so do applications across various sectors. Companies must balance investing in innovation while addressing these imperfections. Growth opportunities are immense, yet vigilance is required in navigating the market landscape. This dynamic environment influences not only industry players but also consumers seeking sustainable energy solutions.

Silicon carbide (SiC) semiconductors have transformed energy solutions. Their ability to operate at high voltages and temperatures sets them apart. As demand for energy efficiency grows, SiC usage rises. Reports estimate the global silicon carbide market will reach $6.71 billion by 2028. This growth highlights the increasing interest in SiC technology.

The advantages of silicon carbide are numerous. SiC devices can switch faster than traditional silicon. This enhances system efficiency, reducing energy waste. Research indicates SiC can improve energy conversion efficiency by up to 20%. In electric vehicles, SiC semiconductors enable longer range with less battery charge. This technology reduces the overall carbon footprint.

However, the adoption of silicon carbide is not without challenges. Manufacturing costs remain high. Supply chain issues can impact availability. Furthermore, not all applications benefit equally from SiC. The market needs more education on optimal uses. Understanding these factors is crucial for future advancements in efficient energy solutions.

Silicon carbide (SiC) semiconductors are revolutionizing energy solutions across various sectors. Their ability to operate at high temperatures and voltages makes them ideal for applications like electric vehicles. In these vehicles, SiC enhances energy efficiency, extending range and reducing charging times. The lightweight nature of SiC devices contributes to overall vehicle performance, a critical aspect in the automotive industry.

In renewable energy, SiC is gaining traction in solar inverters. These inverters convert solar energy into usable power with minimal energy loss. Using SiC technology can lead to more compact, efficient designs. It's not just beneficial for consumers; the reduced energy waste positively impacts the environment. However, challenges remain. Manufacturers still face hurdles in scaling production while maintaining quality. The long-term durability of SiC devices in harsh conditions is yet another area to explore.

Industrial applications also showcase SiC's versatility. In motor drives and power supplies, they allow for smaller, lighter setups without compromising performance. This is particularly useful in automation and robotics. Yet, the initial cost of SiC components can be a barrier for some sectors. As research progresses, engineers are working to address these concerns, paving the way for broader adoption in energy solutions.

| Application | Efficiency Improvement | Key Advantages | Typical Voltage Range |

|---|---|---|---|

| Electric Vehicles | 10-20% increase | Higher efficiency, faster charging | 400V - 800V |

| Renewable Energy Systems | 15-25% increase | Enhanced power conversion | 1kV - 3kV |

| Power Supply Units | 5-15% increase | Compact design, reduced heat | 600V - 1.2kV |

| Industrial Motor Drives | 10-20% increase | Improved torque and performance | 600V - 1kV |

| Smart Grid Solutions | 20-30% increase | Better load management | 1kV - 5kV |

The landscape of silicon carbide (SiC) semiconductors is expanding rapidly. Various manufacturers are competing to offer the best products. Performance, cost, and reliability are essential factors. Each manufacturer focuses on unique aspects to distinguish their offerings. However, this diversity can also lead to confusion for buyers. What sets each option apart?

One critical area of comparison is the substrate quality. Higher quality substrates lead to better performance. Impurities in the material can affect efficiency. Design variations also play a vital role. Some manufacturers prioritize high-temperature applications. Others may focus on high-voltage requirements. These differences can impact long-term reliability.

Innovation is a double-edged sword. While cutting-edge designs may offer better efficiency, they can also introduce complexities. A user-friendly product can sometimes take precedence over advanced technology. Manufacturers must balance innovation with practicality. Assessing which features truly matter is challenging. For consumers, the right choice often involves navigating numerous variables.

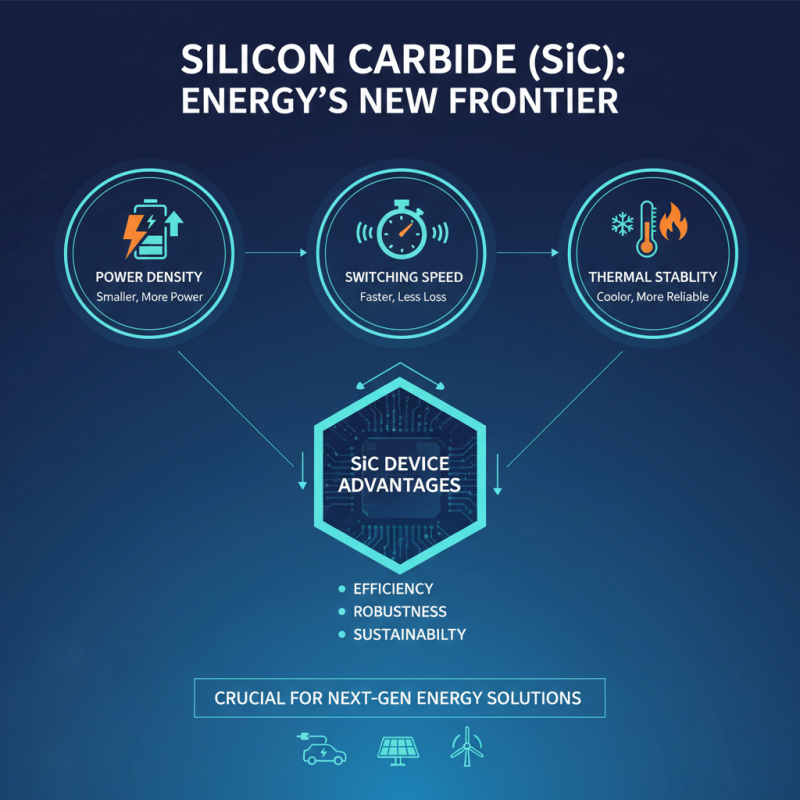

Silicon carbide (SiC) devices are becoming vital in energy solutions. Their efficiency comes from various performance metrics. Metrics play a crucial role in assessing SiC's capabilities. They help in understanding power density, switching speed, and thermal stability.

Power density refers to the amount of power a device can handle. Higher power density translates to smaller devices. However, optimizing power density can lead to thermal issues. Thermal stability is often overlooked but is essential for long-term performance. A device that heats up too quickly may fail prematurely.

Switching speed also matters and affects energy loss. Faster switching reduces energy waste. Yet, achieving the ideal balance between speed and stability is challenging. Evaluating these metrics should be an ongoing process. Continuous testing and refinement lead to better results. In this rapidly evolving field, staying informed will drive innovation and improvement.

Silicon carbide (SiC) technology is transforming energy efficiency. This material excels in high-temperature and high-voltage applications. Its ability to reduce power losses makes it a key player in renewable energy systems. For instance, SiC-based power devices are now common in solar inverters, enhancing their performance.

The future trends in SiC technology show promising directions. Research focuses on improving manufacturing processes. This should lower costs and increase the accessibility of SiC solutions. Furthermore, advancements in material properties can lead to even higher efficiency gains. However, challenges remain. The integration of SiC in existing systems is not straightforward. There can be compatibility issues with traditional silicon components.

As SiC technology evolves, the landscape of energy solutions will change. There’s potential for significant improvements in electric vehicles and industrial applications. But, these advancements will require collaboration across industries. Stakeholders must address sustainability concerns and energy management strategies. The road ahead is exciting yet complex, requiring a balanced approach.