Leave Your Message

Silicon Iron is becoming increasingly vital in various industrial applications. This unique alloy, known for its magnetic properties, serves multiple sectors, from automotive to energy. In 2026, the best Silicon Iron products will stand out due to their enhanced performance and efficiency.

Industries are pushing for materials that meet high standards. Silicon Iron meets these needs effectively. Its ability to reduce energy loss and improve efficiency makes it a popular choice. However, not all products are created equal. Some may not perform as expected, leading to manufacturing challenges.

As we explore the best Silicon Iron products, we must remain critical. Identifying quality can be difficult. Certain brands may fall short on promises made. Therefore, a deep dive into product specifications is crucial. By understanding these intricacies, industries can make informed decisions leading to better outcomes.

Silicon iron is an alloy made primarily of silicon and iron. Its unique composition gives it a range of valuable properties. This material is magnetic and exhibits high resistance to oxidation. These attributes make it ideal for various industrial applications, especially in electrical engineering.

In transformers and motors, silicon iron plays a crucial role. It helps reduce energy losses. However, production methods can be inefficient. Some manufacturers struggle with quality consistency. There are also environmental concerns regarding the manufacturing process. Balancing cost and quality remains a challenge for many in the industry.

Understanding silicon iron’s significance is crucial for modern applications. Its demand is steadily growing, especially in renewable energy sectors. Industries must prioritize sustainable practices while maximizing the alloy's benefits. There is an ongoing need to improve manufacturing techniques. This will ensure that silicon iron remains a key player in industrial advancements.

| Product Name | Silicon Content (%) | Applications | Key Benefits |

|---|---|---|---|

| Silicon Iron A | 15 | Electrical Transformers | High magnetic permeability |

| Silicon Iron B | 10 | Electric Motors | Excellent corrosion resistance |

| Silicon Iron C | 20 | Inductor Cores | High efficiency |

| Silicon Iron D | 5 | Power Transmission | Enhanced energy efficiency |

Silicon iron is a unique alloy known for its magnetic properties. This material is crucial in various industrial applications, particularly in electrical engineering. Its high silicon content enhances electrical resistivity and reduces core losses in transformers and motors. This advantage makes silicon iron essential for efficient energy conversion.

The alloy can be molded into different shapes and sizes. Its ductility allows it to be formed easily. However, there's a trade-off. While it's excellent in specific applications, the production process can be energy-intensive. Additionally, the quality of silicon iron can vary based on the smelting methods used. Contaminants can affect its performance.

One of the key properties is its thermal conductivity. This can impact how silicon iron behaves under fluctuating temperatures. In some cases, it may not perform as expected when subjected to extreme heat. Manufacturers must consider these factors during the design phase. A thorough understanding of the properties is essential for optimizing performance in industrial settings.

The demand for silicon iron products is growing in 2026. Industries rely on these materials for their magnetic properties. Reports show that this market is expected to reach USD 1.5 billion by the end of the year. Manufacturers are innovating to meet this demand. However, some still struggle with production efficiency.

Leading manufacturers focus on enhancing quality and sustainability. They employ advanced melting techniques to reduce waste. In contrast, not all companies have adopted these practices. Some still rely on outdated methods that produce lower-grade silicon iron. This inconsistency in product quality can hinder market growth.

Data indicates that Asia-Pacific is the largest region for these products. The area holds over 40% of the global market share. Yet, infrastructure challenges persist. Companies must address these issues to optimize distribution. Overall, the industry is poised for growth, but attention to quality and sustainability is crucial.

Silicon iron is experiencing innovative applications across multiple industries, revolutionizing processes and products. In the automotive sector, it plays a vital role in electric motor production. Reports suggest that up to 70% of new electric vehicles utilize silicon iron in their powertrains. This material enhances efficiency, yet challenges remain in scalability.

In the renewable energy field, silicon iron magnets are essential for wind turbines. Studies indicate that these components can increase energy output by 15%. However, manufacturers face hurdles in material cost and sourcing. Striking a balance between performance and affordability is crucial for broader adoption.

The electronics industry also benefits from silicon iron, especially in high-frequency transformers. These devices have seen performance improvements of up to 30% due to silicon iron's magnetic properties. Still, developers need to address potential environmental impacts during production. Each application highlights the promise of silicon iron while also exposing areas for improvement.

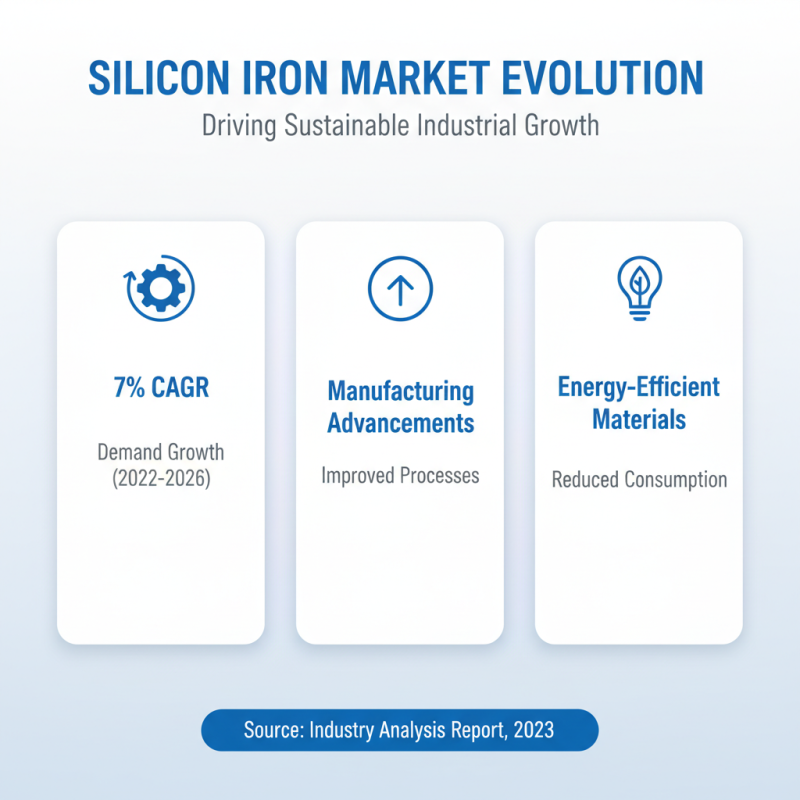

The industrial landscape is evolving, particularly in the production and utilization of silicon iron products. According to a recent industry analysis, the demand for silicon iron is expected to grow by 7% CAGR through 2026. This growth is driven by advancements in manufacturing processes and the rising need for energy-efficient materials.

Future trends indicate a stronger focus on sustainability. Companies are now seeking eco-friendly silicon iron options that reduce energy consumption. Innovative recycling methods are crucial here, as they help minimize waste. A report from the International Energy Agency highlights that using recycled materials can cut emissions by 30%.

**Tip:** Consider sourcing materials from local suppliers. This can significantly reduce transportation emissions.

The development of smart manufacturing technologies is another key trend. Automating processes and integrating AI can significantly enhance production efficiency. However, reliance on technology can also pose risks. Manufacturers must balance automation with skilled labor to avoid job displacement.

**Tip:** Regular training for your workforce can ensure that they remain relevant in an automated environment.

Investing in research and development will be essential. Enhanced properties of silicon iron products can improve performance in various applications. As industries push for higher standards, continuous innovation could be the key to staying competitive.