Leave Your Message

When navigating the industrial landscape, sourcing Silicon Metal becomes essential. This versatile material is critical for various applications. Industries ranging from electronics to construction require high-quality Silicon Metal for optimal performance.

Understanding how to buy Silicon Metal can simplify your procurement process. Not all suppliers offer the same quality. Some may promise low prices but compromise on purity. It's important to focus on reliable sources, as purity levels can greatly affect product effectiveness.

Assess your needs before diving into the market. Consider your specific applications and the attributes of Silicon Metal that are crucial for them. This may include looking at grade, size, and supplier reliability. Investing time in research can pay off significantly, but be aware of potential pitfalls.

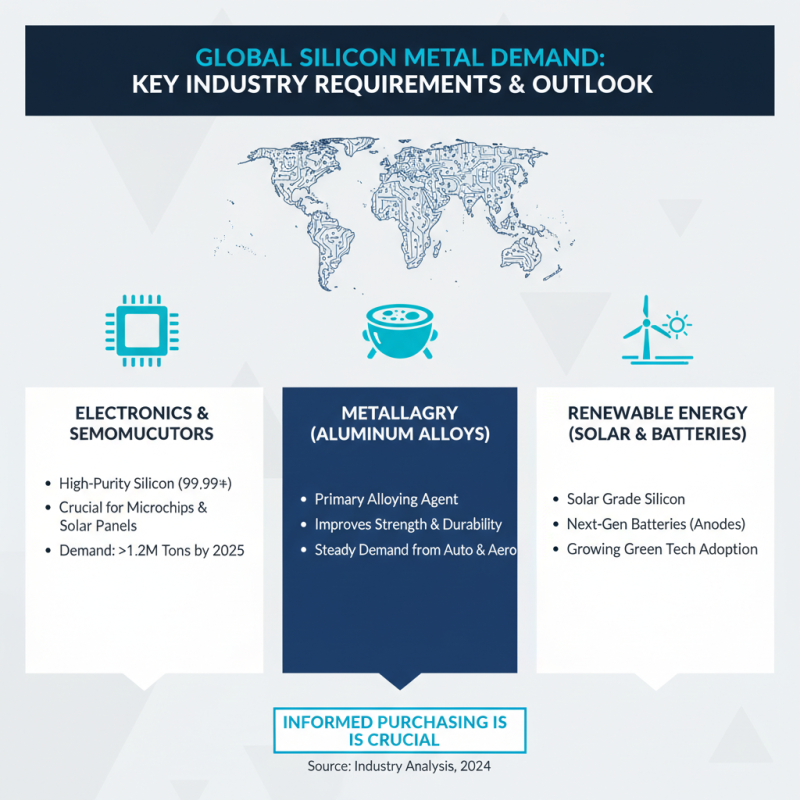

Understanding your industry’s silicon metal requirements is crucial for making informed purchases. Many sectors, such as electronics, metallurgy, and renewable energy, each have specific needs. For instance, the silicon metal demand in the semiconductor industry has grown significantly, projected to exceed 1.2 million tons globally by 2025. This indicates a robust need for high-purity silicon, typically above 99.99% purity, to ensure optimal performance in electronic components.

Identifying your requirements begins with analyzing your application. If your focus is on photovoltaic cells, you may require metallurgical-grade silicon. In contrast, industries producing aluminum alloys may seek silicon that enhances fluidity and strength. Reports suggest that about 60% of silicon metal output is used in aluminum production, highlighting its strategic relevance. It’s essential to review specifications. Lack of clarity about your silicon needs can lead to costly missteps. Are you considering quality or quantity? Do you need a particular type? Your answers shape the types of suppliers you should engage.

Additionally, market volatility can affect pricing and availability. Recognizing trends can assist in strategic planning. Reports indicate that prices for silicon metal fluctuated by more than 20% in the past year alone. Monitoring market conditions and establishing relationships with multiple suppliers can mitigate drawbacks. This approach helps maintain flexibility amid an evolving landscape.

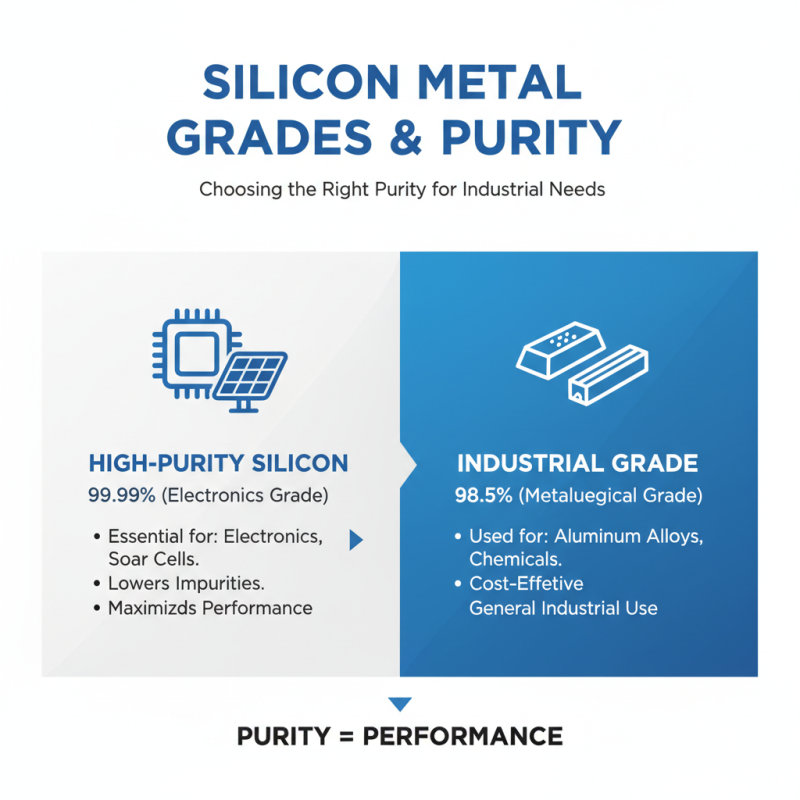

When exploring silicon metal, understanding grades and purity levels is crucial. Silicon metal comes in various grades, often categorized by their purity percentage. Common grades include 99.99% (also known as electronics grade) and lower grades like 98.5%. Each grade serves specific industrial needs. High-purity silicon is essential for electronics and solar applications. A slight impurity can impact performance, so choosing the right grade is vital.

Some industries might hesitate to invest in higher grades due to cost. However, the long-term benefits can outweigh initial expenses. For instance, using 98.5% silicon may suffice for certain metallurgical applications. Yet, it may not perform well in high-tech devices. You need to weigh options carefully. A thorough understanding of your requirements will guide you in selecting the appropriate grade.

Purity levels are equally important. Even trace elements can affect the end product. Silicon with high iron content can weaken structures in metallurgy. Manufacturers should consider testing for impurities before making a purchase. This step ensures you are not unknowingly compromising quality. Examine the supplier's specifications closely to avoid potential pitfalls. Quality control is an ongoing process worth investing in.

When evaluating suppliers for silicon metal, consider both pricing and quality. Price fluctuations are common. In 2022, the average price of silicon metal surged by 40%, driven by increased global demand. Understanding these trends is crucial for evaluating supplier offerings.

Quality assessment is equally vital. High-purity silicon metal (over 98.5% purity) is critical for industries like electronics and solar energy. According to industry reports, low-quality silicon can result in product failures. It's essential to request detailed specifications. Certifications and test results provide insight into a supplier's quality standards.

Not every supplier guarantees consistent quality. Some may offer attractive prices but compromise on purity. Engage in discussions to understand their production processes. Transparency can indicate reliability. Additionally, assess their supply chain stability. A fluctuating supply can lead to production delays. Balancing cost with quality requires careful consideration.

The demand for silicon metal is on the rise. Industries like electronics, automotive, and construction depend heavily on this material. Understanding market trends is vital for businesses aiming to procure silicon metal efficiently. Many factors drive this demand, including technological advancements and the shift towards renewable energy sources.

Tips: Monitor global supply chains for potential disruptions. Sometimes, unexpected events can lead to price fluctuations. Stay informed about industry news. It helps you anticipate changes in demand and adapt your purchasing strategy accordingly.

The market is dynamic, with prices often influenced by production levels and environmental regulations. Emerging applications for silicon metal, like solar panels, add to the complexity. Some buyers might rush their purchasing decisions, leading to regrets later. Evaluating capacity and supplier reliability is essential. Always consider potential risks before making bulk purchases. Your approach should be flexible to adapt to changing circumstances.

When considering importing silicon metal, logistics are crucial. It's not just about finding a supplier. Understanding shipping procedures and customs regulations is essential. Transporting silicon metal requires careful planning to avoid delays. You need to coordinate shipments and ensure they comply with local laws.

Packaging plays a significant role in this process. The material should be secure to prevent contamination or damage. Using proper containers that can withstand transportation stress is vital. Additionally, working with reliable freight companies can make a difference. They can provide insights tailored to your specific needs.

Monitoring your supply chain is also imperative. Developing relationships with suppliers can help streamline logistics. Regular communication reduces risks and helps in managing expectations. Sometimes, issues may arise during shipping that need quick resolutions. Therefore, flexibility and contingency plans are important. Understanding these elements can ultimately enhance your operations and lead to smoother importing processes.