Leave Your Message

Choosing the right materials for your projects can be challenging. Silicon Bronze is a versatile and durable option that deserves your attention. Known for its strength and corrosion resistance, it can be ideal for various applications, from marine environments to artistic sculptures.

When selecting Silicon Bronze, consider the specific needs of your project. Different alloys offer unique properties. For instance, silicon bronze with higher silicon content provides excellent fluidity, which is crucial for casting. If you're welding, a lower silicon alloy may be the best fit. Evaluating these details makes a difference.

As you work with Silicon Bronze, remember that every project may not go as planned. Mishaps can occur, and not every technique will be perfect. Embrace these learning moments as part of the creative process. The key is to stay open to experimentation and make adjustments as necessary.

Silicon bronze is a unique alloy that combines copper with silicon. This mixture gives it standout properties. Key benefits include great corrosion resistance and strength. It’s an excellent choice for marine projects. Boats and hardware can last much longer with this material.

Working with silicon bronze requires some knowledge. The alloy can be challenging to weld. Proper techniques and equipment make a difference. Remember to choose the right filler if welding is needed. The color is appealing too; its warm tones can enhance any project.

However, not every project may suit silicon bronze. Some might find it too costly compared to alternatives. Always assess whether the benefits justify the expense. Understanding limitations can lead to better decisions. Experimenting with silicon bronze might reveal unexpected challenges. Embrace those moments of learning.

When selecting silicon bronze alloys, consider the specific application. For marine environments, C65500 alloy excels due to its corrosion resistance. It is often used in boat fittings. This choice helps in ensuring longevity and durability. For architectural purposes, the C64200 alloy is a popular option. It combines strength and aesthetic appeal. This alloy is frequently found in decorative sculptures and fixtures.

Each alloy has unique properties. The C67000 offers excellent electrical conductivity. It works well for electrical applications. But it may not be suitable for heavy mechanical loads. The C65100, on the other hand, provides higher tensile strength. It's ideal for structural components. However, it can be more challenging to weld.

When working with these materials, understanding their limitations is crucial. Welding silicon bronze requires specific techniques. Overheating can lead to undesired outcomes. Testing small pieces first is wise. The melting temperature varies across alloys. Make notes on your results. Documenting successes and failures can improve future projects. Experimentation often leads to better choices in the long run.

| Alloy Type | Composition | Common Applications | Weldability | Corrosion Resistance |

|---|---|---|---|---|

| C65100 | 90% Copper, 10% Zinc | Marine Applications, Hardware | Good | Excellent |

| C65500 | 88% Copper, 10% Zinc, 2% Silicon | Architectural Elements, Sculptures | Good | Very Good |

| C63000 | 95% Copper, 5% Silicon | Electrical Components, Pumps | Excellent | Good |

| C63200 | 88% Copper, 7% Tin, 5% Zinc | Fasteners, Marine Fixtures | Fair | Excellent |

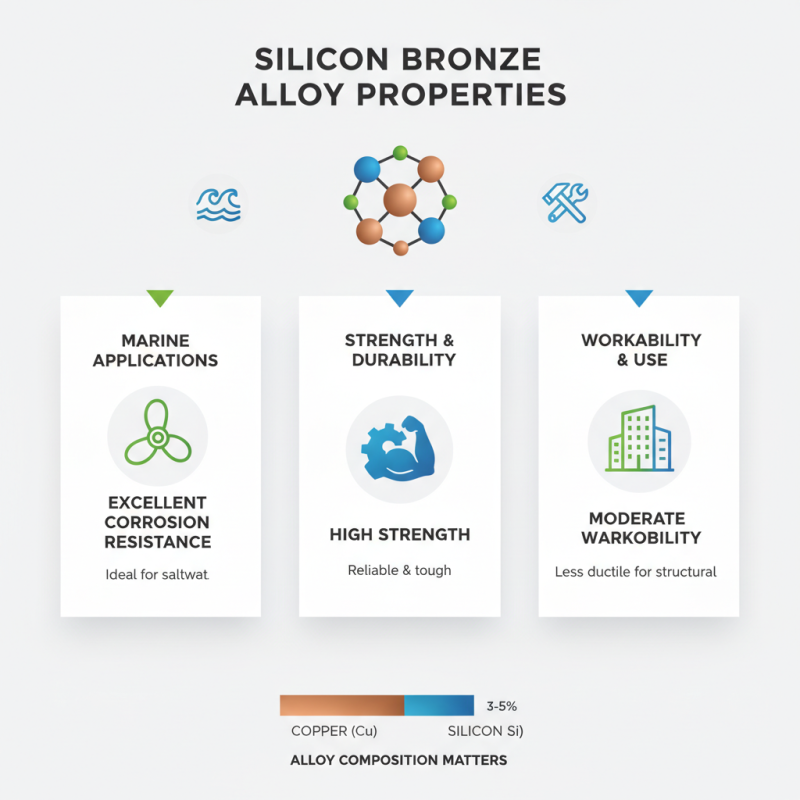

When it comes to selecting silicon bronze for your projects, understanding the alloy's properties is crucial. Silicon bronze is known for its excellent corrosion resistance and strength. If you are working on marine applications, this metal is a solid choice. However, for structural projects, its workability might not meet all expectations. The specific percentages of silicon and copper in the alloy greatly influence its characteristics.

It's essential to analyze your project's requirements. For instance, if you need good weldability, choose a silicon bronze with a higher silicon content. A lower silicon ratio might serve better for machining tasks. Consider the environment as well; extreme moisture can affect performance. While silicon bronze is durable, some users find it prone to pitting in saltwater. Test different alloys on a small scale before full-scale application. It's a step that can save time and resources later. Always reflect on previous choices. Sometimes, unexpected results teach the most valuable lessons.

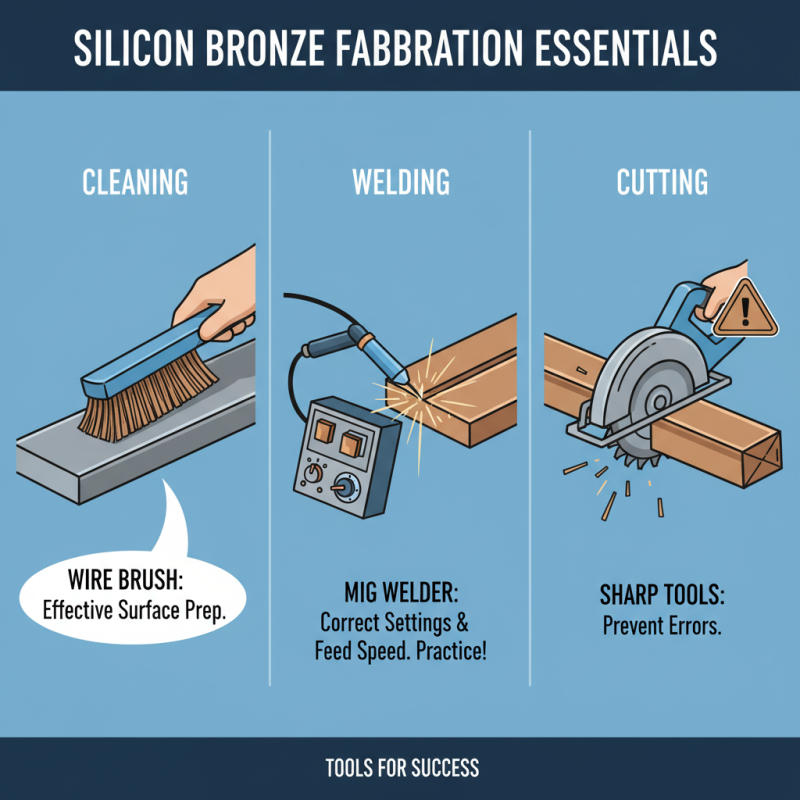

When working with silicon bronze, having the right tools is essential. A good wire brush can clean surfaces effectively. Use a MIG welder for most projects. Ensure it is set to the right parameters for silicon bronze. You might find the feed speed tricky at first. Practice makes perfect. Cutting tools should also be sharp. Dull blades can lead to mistakes.

Preparation is key. Start with a clean workspace. Dust and debris can ruin your work. Use a vice to hold materials firmly. This prevents movement during welding. Don't forget safety gear. A proper helmet protects your eyes from sparks. Gloves are necessary as well.

Technique matters too. Tack welding can help hold pieces in place. Don't weld fully at the start. This method allows adjustments. Sometimes, welds may not be perfect. Don't be hard on yourself; learn from these flaws. Adjust your technique as needed. Patience is important. Silicon bronze can be challenging, but the results are worth it.

Proper maintenance of silicon bronze projects is crucial for longevity and performance. Silicon bronze exhibits excellent corrosion resistance, making it a preferred choice in marine and outdoor applications. However, neglecting upkeep can lead to discoloration and degradation over time. Regular cleaning with mild soap and water can remove dirt and prevent buildup. Despite its durability, silicon bronze can tarnish, losing its luster.

Many industry experts recommend applying a protective wax or a specialized coating to maintain its sheen. A report by the National Association of Corrosion Engineers indicates that nearly 30% of metal failures result from inadequate maintenance. It’s important to inspect your projects frequently. Small signs of wear may indicate deeper issues. Allowing these problems to fester can lead to costly repairs.

If you notice pitting or surface damage, don’t wait. Address the problem early to avoid larger complications. Re-polishing the surface with fine abrasives can restore shine. However, it’s essential to be gentle. Use a soft cloth and avoid harsh chemicals. Remember, maintaining silicon bronze is not just about aesthetics; it’s about preserving function and integrity. Regular maintenance brings both challenges and rewards that are worth the effort.