Leave Your Message

Choosing the right industrial silicon is a critical decision for manufacturers across various sectors, as this versatile material plays a significant role in the production of a wide array of products, from electronics to construction materials. Industrial silicon, known for its unique properties such as high thermal and electrical conductivity, makes it an essential component in the fabrication processes of semiconductors and photovoltaic cells. However, with the diverse range of industrial silicon types available in the market, determining the most suitable option for specific manufacturing needs can be daunting.

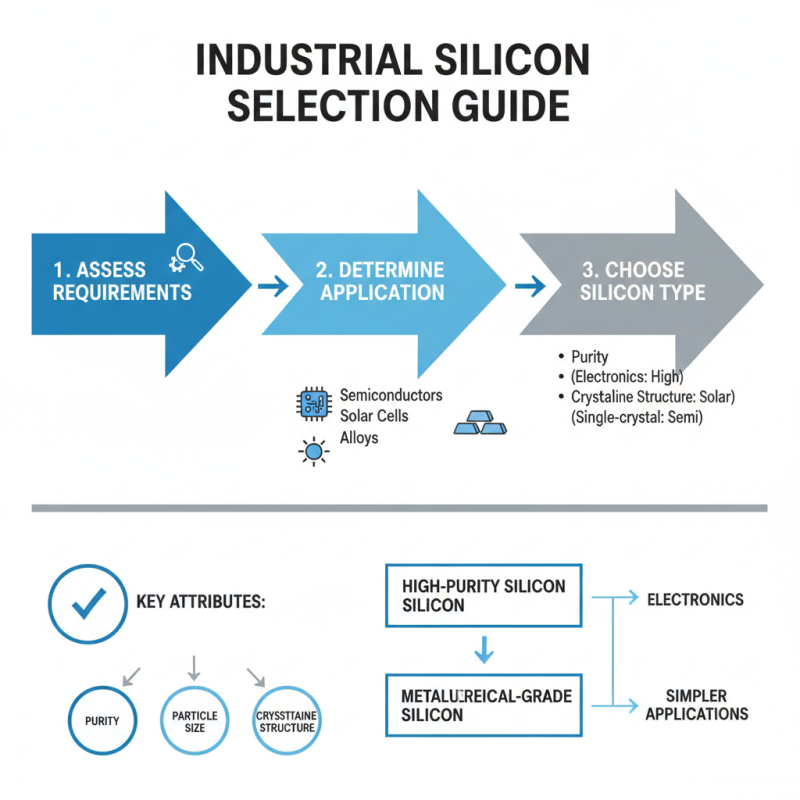

Understanding the specific requirements of your production process is the first step in selecting the right industrial silicon. Factors such as purity levels, physical form, and production processes must be carefully evaluated to ensure that the chosen silicon aligns with your manufacturing goals. Additionally, awareness of the different grades of industrial silicon and their respective applications can help streamline the selection process. This introduction sets the stage for a comprehensive guide to navigating the complexities of industrial silicon selection, ultimately providing manufacturers the insights necessary to make an informed choice that will enhance the efficiency and quality of their production outcomes.

When selecting the right industrial silicon for your manufacturing needs, understanding the different types available is crucial. Industrial silicon primarily comes in two forms: metallurgical silicon and chemical silicon. Metallurgical silicon, typically produced from quartz sand and coke, is largely utilized in the production of aluminum and silicon alloys, comprising around 98% purity. On the other hand, chemical silicon, with purities of 99.9999% or higher, is key for applications in the semiconductor and solar industries. According to a 2021 report by the International Institute for Silicon Research, the demand for chemical silicon is expected to grow by 10% annually, driven by advancements in renewable energy technologies.

Tips: Prior to making a decision, assess your specific manufacturing requirements. If your products require high purity, such as in electronics, investing in chemical silicon is essential despite its higher cost. Alternatively, for lower purity applications, metallurgical silicon may suffice, offering a more economical choice.

Additionally, it’s important to consider the geographical source of your silicon. Countries like China dominate the production market, supplying over 60% of the global silicon needs. However, emerging markets are increasingly contributing to a more diversified supply chain, enhancing availability and potentially stabilizing prices. By keeping these factors in mind, you can choose the most suitable type of silicon that aligns with both your operational demands and budget constraints.

When selecting industrial silicon for manufacturing, one of the most crucial aspects to consider is the quality and purity of the silicon itself. High purity silicon is essential for various applications, particularly in the electronics and solar industries. According to a report by MarketsandMarkets, the global silicon market is expected to reach USD 25.01 billion by 2027, driven by increasing demand for high-grade silicon in semiconductor applications. Therefore, ensuring the silicon you choose meets industry standards is vital.

To evaluate the quality of industrial silicon, manufacturers should focus on parameters such as silicon purity, particle size distribution, and the presence of impurities. A common benchmark is the requirement of 99.9999% purity for silicon used in electronic components, also referred to as "six-nines" purity. The presence of impurities, even in minuscule quantities, can significantly affect the performance and reliability of final products. For instance, impurities like iron and aluminum can drastically alter the electrical properties of silicon wafers, leading to reduced efficiency in solar cells.

Reports have shown that the overall yield of semiconductor devices can decrease by 20% when using silicon with lower purity levels. Therefore, prioritizing high-quality, pure industrial silicon is necessary to optimize manufacturing outcomes.

When selecting the right industrial silicon for your manufacturing needs, it's essential to begin by assessing your specific requirements. Different manufacturing processes demand various forms of silicon, whether for semiconductor fabrication, solar cell production, or alloy creation. Understanding the particular attributes that best suit your applications, such as purity levels, particle size, and crystalline structure, can significantly impact the performance of the end product. For instance, high-purity silicon is crucial for electronics, while metallurgical-grade silicon may suffice for simpler applications.

Additionally, evaluating your production scale and budget is paramount. The quantity of silicon required can influence not only the selection but also the sourcing strategy. Smaller operations might prioritize cost-effective options, while larger enterprises may invest in higher-grade materials to achieve optimal performance and reliability. It’s also advisable to consider the availability of technical support and logistics of procurement to ensure a seamless integration of silicon into your workflow. Balancing these factors will help you identify the most suitable type of industrial silicon that aligns with your manufacturing goals.

When choosing the right industrial silicon for your manufacturing needs, comparing suppliers and their offerings is crucial to ensure quality and cost-effectiveness. According to a recent market analysis by industry leaders, global demand for industrial silicon is projected to reach approximately 3.2 million tons by 2026, driven by its use in various applications such as solar energy and electronics. This growth emphasizes the importance of selecting a reliable supplier who can meet both current and future demands.

When evaluating suppliers, consider factors such as production capacity, quality certifications, and the range of products offered. A comprehensive report from the Silicon Industry Association reveals that the top suppliers typically offer diverse silicon grades tailored for specialized applications, which can significantly enhance the performance of your end products. This kind of specialization is vital to achieving operational efficiency and maximizing yield in manufacturing processes.

**Tips:** Always request samples to assess the purity and performance of silicon before making bulk purchases. Additionally, check for sustainability practices and compliance with environmental regulations, as the industry's shift towards greener practices is increasingly important. Lastly, maintaining open communication with potential suppliers can help you understand their ability to adapt to changing market conditions and your specific requirements.

When selecting the right industrial silicon for manufacturing needs, understanding the balance between cost and value is crucial. The initial purchase price of silicon can vary significantly based on its purity, form, and supplier. However, a lower price does not always equate to good value. It is essential to evaluate the long-term benefits associated with higher-quality silicon, such as improved efficiency, reduced waste, and enhanced performance in final products. Making a cost-effective decision requires not just analyzing the upfront expenses but also considering the lifecycle costs and potential savings that high-quality materials can provide.

Additionally, evaluating the specific requirements of your manufacturing process is vital. Different applications may demand varying qualities of silicon, which can affect overall production quality and cost efficiency. For instance, silicon with higher purity levels might be necessary for electronic applications, while others may suffice for construction purposes. Engaging in thorough research on the performance characteristics required for your applications can guide you towards a silicon choice that maximizes value relative to its cost, ensuring that your investment leads to optimal production outcomes.

| Silicon Type | Purity % | Cost per KG ($) | Applications | Value Proposition |

|---|---|---|---|---|

| Polycrystalline Silicon | 99.9999% | 30 | Solar Cells, Electronics | High efficiency for solar energy conversion |

| Monocrystalline Silicon | 99.99999% | 50 | Semiconductors, Solar Panels | Higher efficiency and space savings |

| Amorphous Silicon | >98% | 20 | Thin-film Solar Cells | Flexible and lightweight, ideal for building-integrated PV |

| Silicon Carbide | 99.99% | 80 | High Power Electronics, LED Technology | Superior thermal conductivity and electric field strength |