Leave Your Message

Choosing the right Silicon Carbide Crucible is crucial for various industrial applications. These crucibles are known for their high thermal conductivity and resistance to thermal shock. According to a recent industry report, the demand for Silicon Carbide Crucibles is expected to grow by approximately 5% annually.

When selecting a crucible, consider the specific requirements of your operation. Factors such as temperature range, chemical resistance, and size are vital. Some manufacturers offer varying grades of Silicon Carbide Crucibles, each tailored for different applications. For example, high-purity options are preferred for applications that require minimal contamination.

However, not all crucibles may meet your expectations. Inconsistent quality can lead to failures during usage. It’s essential to assess supplier reviews and product specifications carefully. Remember, the most expensive option is not always the best one. Therefore, evaluating both performance data and application needs can guide you to the ideal Silicon Carbide Crucible for your needs.

Silicon carbide crucibles are widely used in various industries. They are highly durable and resistant to extreme temperatures. This makes them suitable for applications like metal casting and glass manufacturing. Crucibles made from silicon carbide can withstand harsh conditions. They provide excellent thermal conductivity, ensuring even heating during processes.

When selecting a crucible, consider your specific needs. The size and shape are crucial factors. Small crucibles work well for precision tasks, while larger ones suit bulk operations. Think about the materials you will be melting or processing. Some materials may react with certain crucibles. Careful selection is essential for safe and efficient operations.

Tips: Always check the maximum temperature rating. This ensures the crucible will not fail during use. Additionally, assess the crucible's compatibility with your materials. This can prevent unwanted reactions. Finally, read user reviews for practical insights. Real-world experiences can shine a light on the performance of various options.

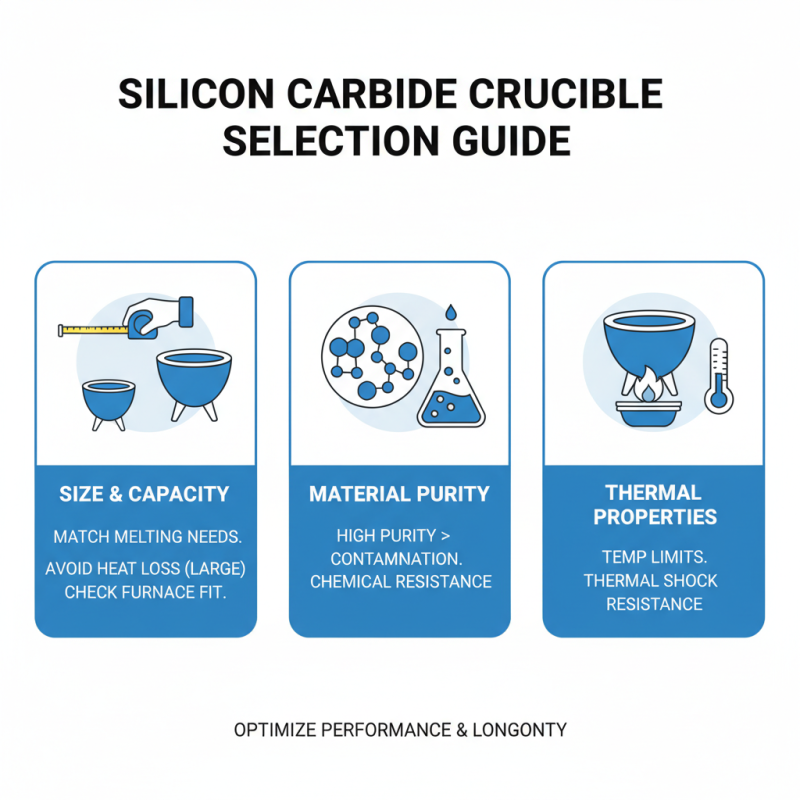

When selecting a silicon carbide crucible, there are key factors to consider. The size and capacity of the crucible are crucial; they need to match your specific melting requirements. A larger crucible may be tempting, but it can lead to heat loss. Ensure it fits your furnace space effectively.

Material composition matters too. Different grades of silicon carbide offer various benefits. Higher purity levels withstand extreme temperatures better. However, they often come at a premium. Weigh the performance gain against the cost. The choice you make can affect the lifespan of the crucible.

**Tip:** Conduct experiments with different sizes and materials. Document your findings. This helps you understand your needs better.

Another aspect is thermal shock resistance. If your process involves rapid temperature changes, you need a crucible that can handle that. Poor resistance could lead to cracks or failures. Consider your operation's temperature fluctuations. A proper assessment is key.

**Tip:** Check user feedback from colleagues in the industry. Real-life experiences can lead you to better choices.

Ultimately, finding the right silicon carbide crucible requires careful evaluation of your specific needs and processes. Balancing cost, material properties, and thermal performance is essential.

When selecting a silicon carbide crucible, understanding the various types available is essential. Silicon carbide, renowned for its high thermal conductivity, comes in several forms tailored to specific applications. For instance, there are standard crucibles, designed for routine melting of metals. Then, there are high-purity crucibles, often used in semiconductor production. These high-purity options minimize contamination, making them vital in precision industries.

In a recent industry report, around 65% of users noted that durability is a critical factor. Silicon carbide crucibles can withstand extreme temperatures, often exceeding 1600 degrees Celsius. This property is crucial, especially in foundries and laboratories. However, a common oversight is the failure to consider the size and shape appropriate for their furnaces. Choosing an incompatible crucible can lead to inefficiencies and increased costs.

Moreover, compounding the situation is the variation in manufacturing processes. Some crucibles feature added reinforcements for greater stability. Yet, not all manufacturers provide clarity on material specifications. This lack of transparency can make it challenging to assess the crucible's true capabilities. As such, users must be informed and discerning when selecting a crucible that genuinely meets their operational needs.

To maintain and extend the life of your silicon carbide crucible, regular care is essential. Keep it clean and free from contaminants. After each use, allow it to cool slowly. Rapid cooling can lead to cracks. Use a soft brush or cloth to remove any residue. Avoid using harsh chemicals that could harm the crucible’s material.

It's vital to pay attention to the temperature limits of your crucible. Exceeding these limits can create stress fractures. Make sure to preheat the crucible gradually. This helps to distribute heat evenly. Also, avoid thermal shock by not placing a hot crucible on a cold surface. Remember, small actions can lead to significant changes.

Inspect your crucible regularly for signs of wear. Look for any chips or cracks that may form over time. Minor damage can escalate if not addressed promptly. Store your crucible in a safe place where it won't get knocked over. If it's necessary to stack, use a protective layer between them. Simple precautions can save you from premature replacements.

Choosing the right silicon carbide crucible can be challenging. One common mistake is not assessing the thermal shock resistance. Crucibles can face extreme temperatures. A failure to consider this factor may result in cracking or quick deterioration. According to industry reports, improper thermal resistance can reduce the lifespan of a crucible by up to 40%.

Another mistake is neglecting the crucible's chemical compatibility. Different applications require different chemical resistances. If a crucible isn’t compatible with the materials it holds, reactions may occur. Such incidents can lead to contamination or structural failure. Research indicates that 25% of crucible failures are linked to chemical incompatibility.

Many users also overlook the importance of size and shape. A crucible that is either too large or too small may cause operational inefficiencies. The right size ensures optimal heating and material utilization. Accuracy in measurements can prevent problems later in production. Several case studies highlight that 30% of crucibles are incorrectly sized, leading to significant waste.