Leave Your Message

Choosing the right Silicon Steel for your project can be a daunting task. The industry is vast and complex. According to a report by Market Research Future, the global Silicon Steel market is expected to grow at a CAGR of 6.9% from 2021 to 2027. This growth reflects increasing demand in the automotive and energy sectors.

Expert Dr. John Thompson, a leading figure in the Silicon Steel industry, emphasizes, “Selecting the appropriate grade of Silicon Steel can optimize efficiency and reduce costs.” It’s essential to consider not just electrical properties but also the manufacturing process and end-use application. Many professionals overlook subtle variations in alloy composition that can significantly impact performance.

Understanding these nuances is critical. Distinguishing between non-oriented and oriented Silicon Steel can determine success in your project. Not all Silicon Steel is created equal. Choosing the wrong type may lead to inefficiencies down the line. Being informed and asking the right questions can make all the difference.

Silicon steel, often used in electrical applications, has unique composition and properties. It usually contains around 3% silicon, which enhances its electrical conductivity and magnetic properties. This specific alloying element improves the material’s performance in transformers and electric motors. The higher silicon content lowers energy loss during operation.

The manufacturing process of silicon steel can vary. Some methods produce grain-oriented steel, which is highly efficient for magnetic applications. However, not all grades are ideal for every project. It's crucial to understand how these materials behave under different conditions. Heat, for instance, can alter their properties significantly.

Choosing the right type requires careful consideration. Some projects might benefit from low core loss variations, while others may need high permeability. It's a balancing act that requires reflection and analysis of needs. Users often overlook the importance of coatings, which can protect the steel from oxidation. This detail can impact the steel's longevity and efficiency.

| Grade | Silicon Content (%) | Electrical Resistivity (μΩ·m) | Magnetic Flux Density (T) | Core Loss (W/kg) |

|---|---|---|---|---|

| SiFe 1.5% | 1.5 | 50 | 1.8 | 0.85 |

| SiFe 3% | 3.0 | 40 | 1.95 | 0.75 |

| SiFe 6% | 6.0 | 35 | 2.1 | 0.65 |

| SiFe 9% | 9.0 | 30 | 2.3 | 0.55 |

Silicon steel is crucial in electrical applications. It has unique magnetic properties that make it ideal for transformers and electric motors. Two key types stand out: non-oriented and oriented silicon steel.

Non-oriented silicon steel is commonly used in various applications. It offers decent magnetic performance in multiple directions. Despite its versatility, it may not always provide maximum efficiency. This can sometimes lead to losses in energy. Designers often use it for low- to medium-performance applications.

Oriented silicon steel, on the other hand, excels in specific situations. It has a grain structure aligned to enhance magnetic performance in one direction. This type is often used in high-efficiency transformers. However, it can come with higher costs and is more complex to manufacture. Users must consider these factors when choosing the right material. Balancing performance with budget is often a challenge.

This chart illustrates the various types of silicon steel commonly used in electrical applications, highlighting the number of applications for each type. Grain-oriented silicon steel is primarily used for transformers, while non-grain-oriented varieties are used in motors and other devices.

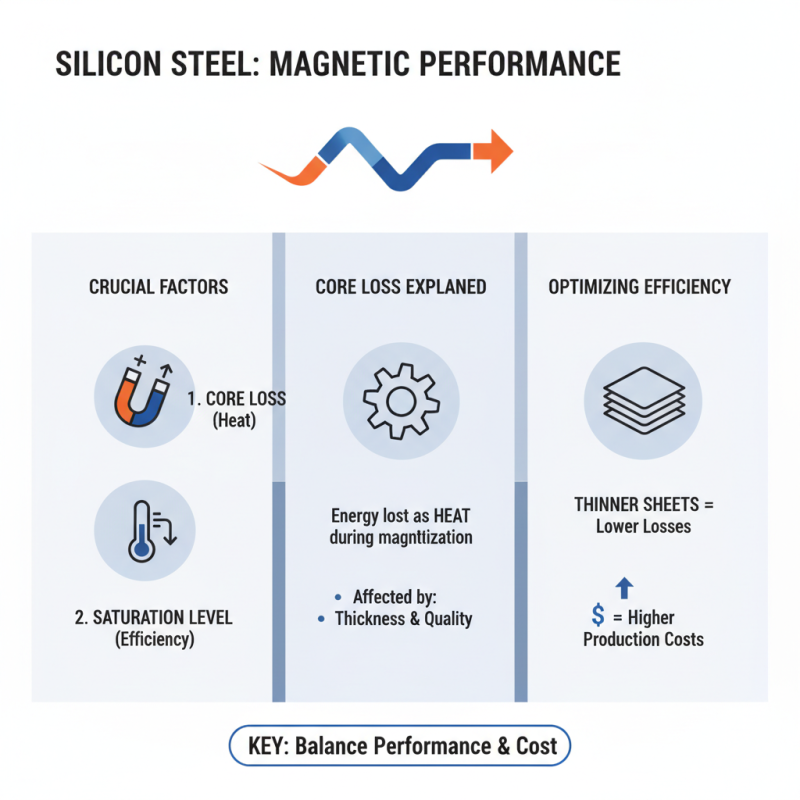

When selecting silicon steel for your project, magnetic performance is crucial. Core loss and saturation levels significantly impact efficiency. Core loss refers to energy lost as heat during magnetization cycles. It can be affected by thickness and quality of the steel. Thinner sheets often reduce losses but may increase production costs.

Saturation levels denote the maximum magnetic flux density the material can handle. Exceeding this threshold can lead to inefficiencies. Understanding the magnetic properties helps in designing effective electromagnetic devices. However, obtaining the right balance between core loss and saturation can be challenging. Trade-offs often emerge: higher saturation might increase core loss, or vice versa.

It’s common to overlook these aspects in initial assessments. Many projects suffer due to inadequate evaluation of magnetic performance. Users must dedicate time to testing various grades of silicon steel. Real-world applications reveal surprising behaviors that theoretical models often miss. Take time to analyze and reflect on these complexities to enhance project outcomes.

Choosing the right silicon steel involves careful consideration of heat treatment and mechanical properties. Heat treatment is crucial for enhancing the magnetic performance of silicon steel. Different treatments can alter its hardness and electrical conductivity. This variation affects how well the steel performs in different applications.

Mechanical properties such as tensile strength and ductility also play significant roles. A balance is necessary; too much strength can reduce ductility. Consider testing samples before making a final decision. The process of selecting suitable silicon steel is not straightforward. It requires reflection on the application demands.

It's easy to overlook the impact of machining conditions. Some are more sensitive to changes in composition during processing. Additionally, understanding the specific requirements of your project is vital. Mistakes in choices can lead to performance issues later on. Therefore, thorough testing and analysis cannot be underestimated.

When selecting silicon steel for your project, understanding cost versus performance is crucial. Different grades of silicon steel offer various benefits. Higher grades may enhance performance but can increase costs significantly. It's essential to find a balance that suits your project's budget and requirements.

Consider your specific application. If magnetic properties are a priority, investing in a higher-grade material might pay off. However, if your needs are basic, a lower grade can suffice. Take the time to explore different options available. Conducting a cost analysis could reveal unexpected insights. Don't overlook lower-cost materials; they may provide adequate performance for your needs.

Reflecting on past choices can help refine your decision-making process. Did you compromise too much on cost? Did it affect performance? Learning from these questions can guide you to the right silicon steel. Remember, the ideal material is one that aligns with your project goals while keeping an eye on expenses. Making informed decisions leads to better outcomes.