Leave Your Message

When selecting a Silicon Carbide Heating Element, several factors come into play. Understanding these factors can lead to more effective and efficient heating solutions. Silicon carbide is known for its high thermal conductivity and stability. However, choosing the right elements is not straightforward.

It’s vital to assess the specific application and desired outcomes. Different industries require different heating temperatures and configurations. Not all Silicon Carbide Heating Elements are created equal. Some may perform better in certain environments than others. This variability can be surprising, sometimes leading to disappointing results.

Consider the longevity and durability of the elements as well. A well-chosen Silicon Carbide Heating Element can last for years, but a poor choice might lead to frequent replacements. This not only incurs costs but also affects productivity. Making informed decisions is crucial, yet many overlook essential details. Reflecting on these aspects could save time and money in the long run.

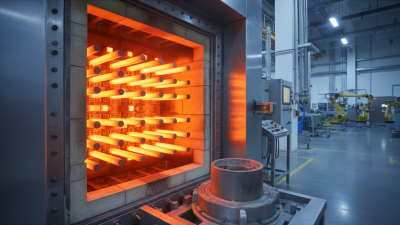

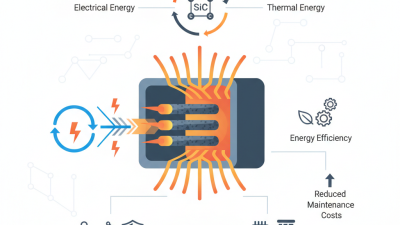

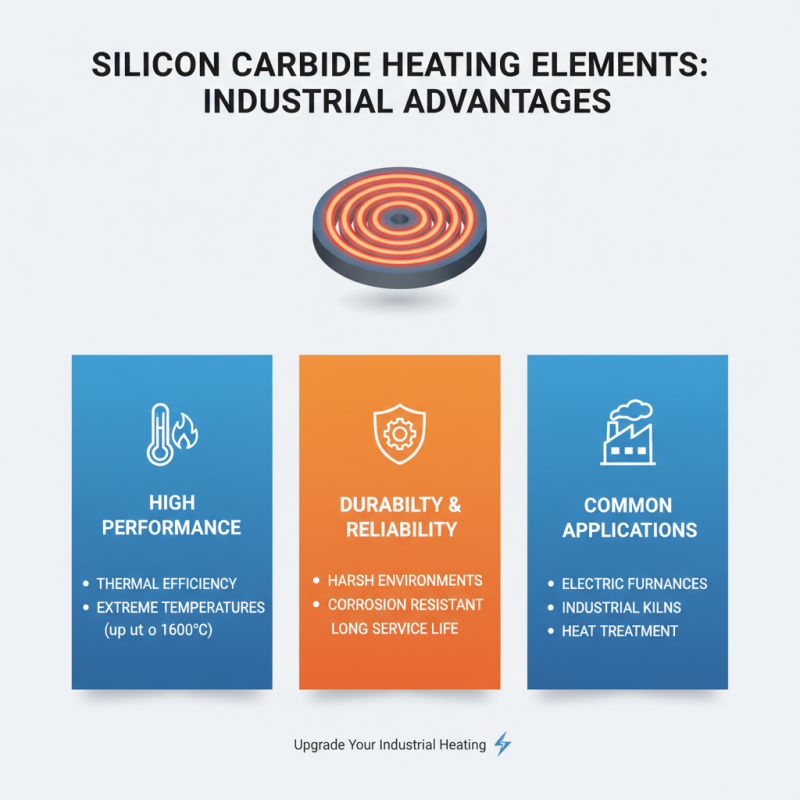

Silicon carbide heating elements are becoming increasingly popular in industrial applications. They are known for their high thermal efficiency and durability. These heating elements can withstand extreme temperatures and harsh environments, making them suitable for a variety of processes. For instance, their use in electric furnaces and kilns showcases their ability to perform reliably under intense conditions.

When considering silicon carbide heating elements, it's crucial to evaluate their specific applications. They excel in industries like ceramics and metal processing. However, selecting the right one can be complicated. Not all silicon carbide elements are the same; some may fail to meet the specific standards required for certain tasks. This variability could lead to unexpected downtimes.

Furthermore, one must reflect on the environment they will be operating these elements in. While they perform well in many scenarios, the wrong choice can cause inefficiencies. Some factors include the operating temperature, atmosphere, and even the physical layout of the installation. Ignoring these nuances may result in suboptimal performance and higher energy consumption. Therefore, careful consideration is key when integrating silicon carbide heating elements into industrial processes.

When selecting silicon carbide heating elements, understanding temperature ratings is crucial. These ratings indicate the maximum temperature the element can withstand. Different applications demand different temperature levels. There are various ranges, often between 1400°F and 2500°F. Knowing your specific needs can prevent future issues.

Performance specifications are another key aspect. Look beyond surface-level data. Factors like heat distribution and response time are vital. Elements with poor heat distribution can lead to uneven heating. This can impact efficiency and product quality. A quick response time ensures the heating element adapts swiftly to changes, maximizing control.

It's also worth considering the longevity of the heating elements. Some may claim longer life, but not all performance metrics correlate perfectly with durability. Sometimes, elements that perform well under specific conditions fail when those conditions change. Conducting thorough testing and real-world evaluations is important. Different environments and practices will reveal the true capabilities of these heating elements. Don't overlook the need for adaptability in performance.

When selecting silicon carbide heating elements, assessing compatibility with your heating system architecture is crucial. The right fit can significantly impact efficiency and performance. According to a 2020 industry report, around 30% of heating issues stem from incompatibility with system design. This statistic highlights the importance of thorough pre-installation evaluations.

Compatibility involves checking voltage, wattage, and physical dimensions. Many systems cannot handle extreme temperatures, which can lead to failure. An incompatible element may cause uneven heating. This could waste energy. Further, system architecture must accommodate specific thermal management needs. If ignored, even the best silicon carbide elements may underperform.

It’s also worth considering future scalability. Your heating system may need upgrades or expansions. A poor choice today can limit options later. Experts suggest that at least 25% of heating systems are not future-proofed. Being mindful of compatibility ensures longevity and efficiency. Even with silicon carbide’s benefits, misalignment with existing architecture can hinder performance and increases costs down the line.

| Tip Number | Tip Description | Considerations |

|---|---|---|

| 1 | Assess Maximum Temperature | Ensure elements can handle required temperatures of your heating application. |

| 2 | Check Power Requirements | Verify the power rating matches your system's energy supply. |

| 3 | Evaluate Compatibility with Environment | Consider factors like humidity and corrosiveness. |

| 4 | Choose the Right Element Shape | Select shapes that fit a specific design for efficient heating. |

| 5 | Consider Element Lifespan | Evaluate the expected lifespan to ensure economic feasibility. |

| 6 | Assess Thermal Distribution | Ensure even heat distribution across the application area. |

| 7 | Inspect Installation Requirements | Check if any special tools or mounting hardware are needed. |

| 8 | Analyze Cost versus Performance | Weigh the cost of elements against their expected performance. |

| 9 | Review Manufacturer Support | Consider the availability of technical support and resources. |

| 10 | Seek User Reviews | Look for reviews from other users to assess reliability. |

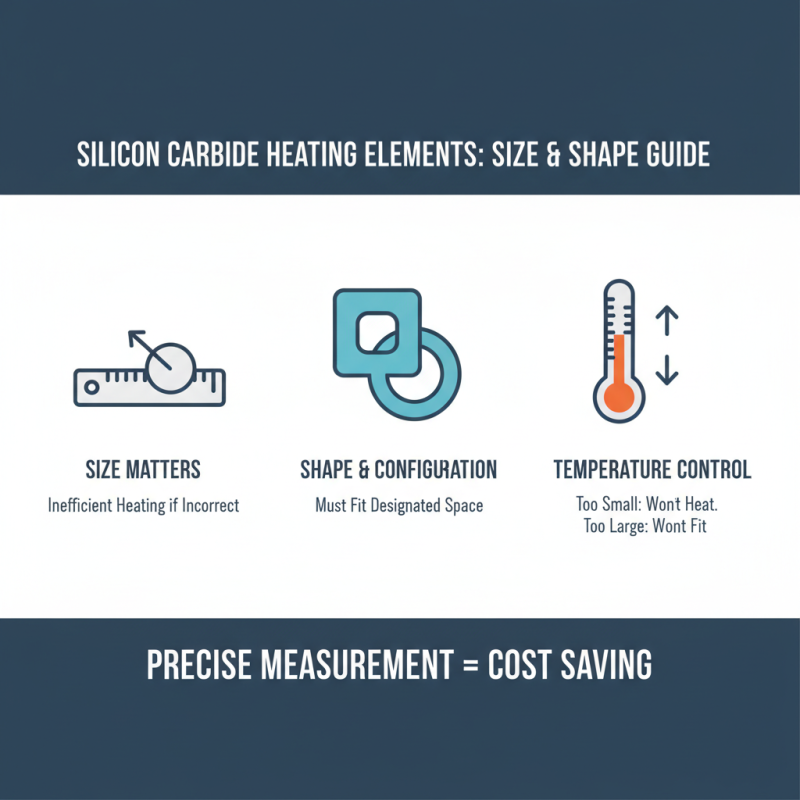

When choosing silicon carbide heating elements, size, shape, and configuration matter significantly. Misjudging the dimensions can lead to inefficient heating. For instance, if an element is too large, it may not fit in the designated space. Conversely, a small element might struggle to reach the required temperatures. Careful measurement can prevent costly mistakes.

Contemplating the shape is vital too. A straight element works well for linear heating. But, for areas needing uniform heat, a coiled shape can be more effective. Compatibility with your setup is crucial. Additionally, configuration must align with application needs. Some setups require vertical elements while others may demand horizontal ones. Overlooking these configurations can lead to poor performance.

Even minor details can make a big difference. Remembering to consider thermal recovery rates is essential. This can impact overall efficiency. Drawing from earlier experiences may help shape your choices. Reflecting on past buying mistakes allows for better decisions now. Ultimately, a thoughtful consideration of these factors leads to a more effective heating solution.

When selecting silicon carbide heating elements, cost plays a significant role. Initial costs can vary widely. Higher-priced options may offer better quality and efficiency. However, it’s crucial to assess long-term savings. If a cheaper option fails quickly, replacement costs can escalate. Investing in a reliable heating element can provide peace of mind and reduce future expenses.

Longevity is another critical factor. Silicon carbide heating elements are known for their durability, but this can vary. Consider the expected lifespan based on operating conditions. Elements subjected to extreme temperatures may wear out faster. Regular maintenance checks are essential to ensure optimal performance. Neglecting maintenance can lead to unexpected breakdowns and costly repairs.

Maintenance factors should not be overlooked. Simple cleaning routines can enhance the lifespan of heating elements. A visual inspection can catch potential issues early. However, not everyone allocates time for this. A lack of regular maintenance may lead to inefficiencies. Therefore, understanding the balance between upfront costs, durability, and upkeep is vital in making an informed choice. Consider how your operating environment may impact these factors as well.