Leave Your Message

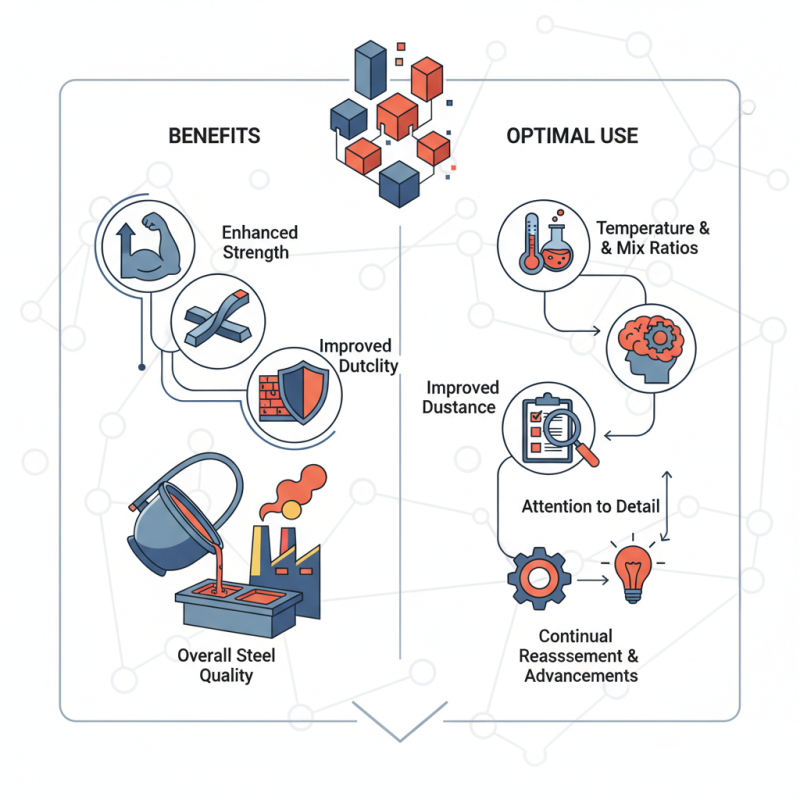

Ferro Silicon Magnesium, often used in steelmaking, offers notable benefits. This alloy enhances strength, ductility, and resistance to corrosion. When used properly, it improves the overall quality of steel products.

Using Ferro Silicon Magnesium requires attention to detail. Optimal use involves understanding the specific needs of your application. Factors like temperature and mix ratios are critical. Neglecting these can lead to suboptimal results, causing disappointment.

Incorporating Ferro Silicon Magnesium can transform your operations. However, it is essential to continually reassess your methods. Adjustments may be necessary to achieve the best outcomes. Keeping an eye on advancements in alloying practices can also provide valuable insights for ongoing improvement.

Ferro silicon magnesium plays a crucial role in metallurgy. It is a key additive for producing ductile iron. This material enhances the mechanical properties of cast iron, increasing tensile strength and ductility. Reports indicate that using ferro silicon magnesium can raise tensile strength by up to 25%. This improvement is vital for applications in automotive and construction industries.

In the melting process, maintaining proper temperature is essential. Ferro silicon magnesium works best when added at temperatures around 1380°C. Timing matters too; adding it too late can lead to incomplete reactions. The alloying process can be delicate. Adjusting composition ratios can yield different results. A study shows that a balanced mix can improve both fluidity and castability of iron.

Despite its benefits, there are challenges. The quality of raw materials can impact the final product. Contaminants can lead to weaker metallurgical structures. Regular quality checks are necessary to avoid defects. Users should be cautious with storage. Exposure to moisture can degrade ferro silicon magnesium. Proper handling techniques are key for optimal results.

| Benefit | Description | Optimal Use Tips |

|---|---|---|

| Improved Ductility | Ferro silicon magnesium enhances ductility in cast iron. | Use in the production of ductile iron for better mechanical properties. |

| Increased Strength | It increases the tensile and yield strength of alloys. | Incorporate in steelmaking processes to enhance the final product's strength. |

| Better Fluidity | Improves the fluidity of the molten metal during casting. | Add during the melting phase to achieve smoother casting. |

| Reduced Shrinkage | Helps reduce shrinkage defects in cast forms. | Maintain optimal temperature control during pouring to minimize defects. |

| Enhanced Wear Resistance | Increases resistance to wear and abrasion in metal products. | Use in applications subjected to high wear conditions for improved longevity. |

Ferro silicon magnesium is a powerful alloy used in various applications. Its benefits include improved strength and ductility in materials. However, to achieve these advantages, understanding optimal application techniques is crucial.

When adding ferro silicon magnesium during the production process, the timing can affect the outcome. If added too early, it may not blend well. If added too late, the desired properties may not fully develop. A precise approach is essential. The temperature must also be carefully monitored for optimal results. Too high a temperature can lead to losses in valuable elements.

In addition, regular quality checks during usage can enhance the final product. Noting any variations is vital; more consistent results are preferred. Often, refining techniques can be beneficial, but it requires constant attention. There are risks in each step, but learning from past applications can guide future efforts. Careful experimentation may lead to better outcomes over time.

Ferro silicon magnesium (FeSiMg) plays a significant role in the metallurgy industry. It is widely used for improving the properties of cast iron. Compared to other alloys, FeSiMg offers distinct advantages. It enhances the fluidity of molten metal. This results in better casting performance in various applications.

When evaluating FeSiMg against alternatives like pure magnesium or silicon alloys, it is crucial to recognize their specific advantages and drawbacks. Pure magnesium can provide higher strength but is more expensive. It may not be as effective in promoting cast iron's desired properties. Silicon alloys can enhance thermal stability but might lack in ductility compared to FeSiMg.

Using FeSiMg requires careful consideration of the material's origins and application contexts. It may not always be the perfect solution for every casting challenge. Each alloy has its characteristics. Misjudging the right type can lead to mechanical failures. Reflecting on these factors can guide better choices in material selection, ensuring optimal performance in final products.

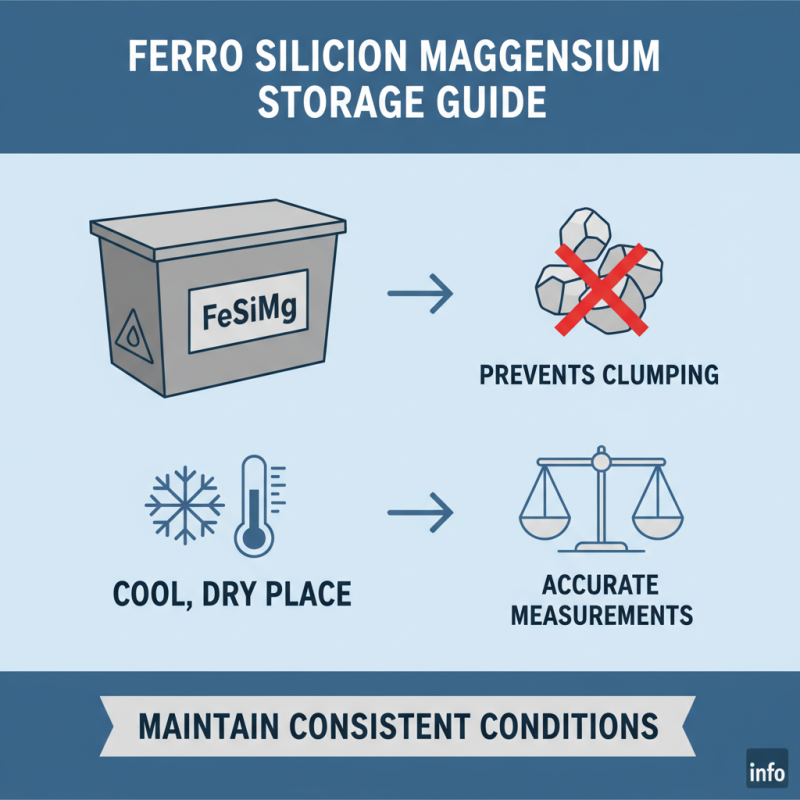

When handling ferro silicon magnesium, proper storage is crucial. Keep it in a cool, dry place. Excess moisture can cause clumping. This clumping may lead to inaccurate measurements. It’s vital to maintain consistent environmental conditions.

Always use appropriate containers to store ferro silicon magnesium. These containers should be sealed tightly. This prevents contamination and oxidation. Regularly check for leaks or damage. If you find any issues, address them promptly. Loses during a handling mishap can be costly.

Transporting ferro silicon magnesium requires care. Use suitable equipment to avoid spills. Always wear personal protective equipment during handling. Protective gear is often overlooked. However, it is essential for safety. Training staff on correct handling practices can help reduce accidents and waste.

Ferro silicon magnesium (FeSiMg) plays a vital role in the steel and iron industries. Its use, however, comes with environmental considerations that deserve attention. A report by the International Energy Agency highlights that the production of ferro alloys, including FeSiMg, contributes to about 6% of global energy consumption in the metal sector. This places an emphasis on the sustainability aspect of its usage.

When using FeSiMg, it's crucial to focus on reducing waste. Ensuring that the right amount is applied during production minimizes excess use. This not only protects the environment but also improves cost-effectiveness. Recycling practices should be implemented. According to a study by the European Steel Association, recycling up to 70% of ferro alloys can significantly reduce CO2 emissions linked to production.

Awareness of emissions during processing is essential. A report by the World Steel Association states that direct emissions from steelmaking can reach 1.8 billion tons annually. Striving for lower emissions can dictate how industries choose their materials and methods. Implementing technologies that capture and utilize this carbon can be a step forward in achieving sustainability. It's a challenge worth reflecting on for future production processes.

This chart illustrates the key benefits of using Ferro Silicon Magnesium in various industrial applications, highlighting its environmental impact and sustainability aspects.