Leave Your Message

Ferro Silicon Manganese is a vital alloy in the steelmaking industry. As we look towards 2026, understanding its role becomes crucial. Industry expert Dr. Lisa Chen notes, "The demand for Ferro Silicon Manganese is expected to soar as industries focus on quality steel production."

This alloy enhances the strength and durability of steel. It is essential for producing high-grade steel used in construction and automotive applications. Various manufacturers are exploring innovative uses for Ferro Silicon Manganese, driven by technological advancements.

Still, challenges persist. The fluctuating prices of raw materials can impact production costs. Moreover, environmental regulations may pose hurdles for production processes. Addressing these issues is vital for the future of Ferro Silicon Manganese in the global market.

Ferro Silicon Manganese is an alloy that contains iron, silicon, and manganese. It plays a crucial role in steelmaking and metallurgy. This alloy improves the strength and toughness of steel. It enhances castability and improves resistance to oxidation. The production process involves smelting manganese ore and silicon in a furnace. The exact composition can vary, impacting its properties.

Many industries rely on Ferro Silicon Manganese for manufacturing high-performance steels. It is used in automotive components, construction materials, and machinery. Additionally, it improves the weldability of steel. The alloy's effectiveness in these applications cannot be underestimated. Businesses need to consider sourcing the right materials to meet industry standards.

Tips: Ensure proper storage of Ferro Silicon Manganese to maintain its quality. Avoid moisture, which can cause oxidation. Always check supplier certifications to guarantee material integrity. Understand the applications you intend to use the alloy for, as this will affect your purchasing decisions.

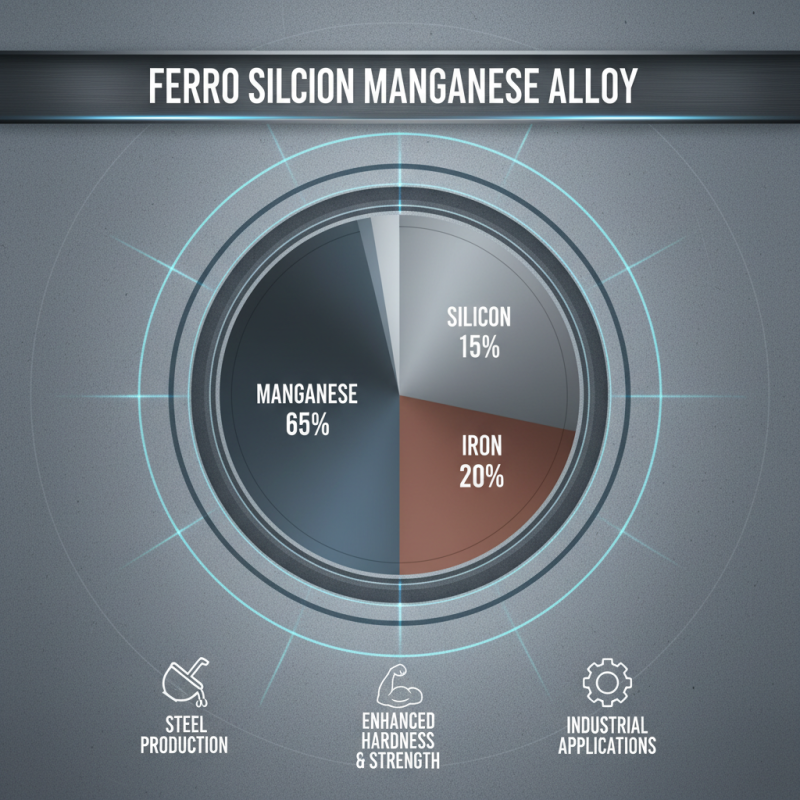

Ferro Silicon Manganese is an alloy consisting of iron, silicon, and manganese. Its chemical composition typically features around 65% manganese, 15% silicon, and the balance being iron. This unique mixture gives it specific properties that are valuable in various industrial applications. The high manganese content enhances the alloy's hardness and strength, making it ideal for steel production.

The properties of Ferro Silicon Manganese are impressive. It serves as a powerful deoxidizer in steelmaking, improving the quality of steel produced. Additionally, it helps to improve corrosion resistance, essential for many applications. Its low melting point can also aid in welding processes, making it a versatile material in metal fabrication. However, producing this alloy can create environmental concerns. Inefficient smelting processes may lead to waste and emissions that require careful management.

In 2026, Ferro Silicon Manganese will shine in multiple sectors, particularly in manufacturing stainless steels and high-strength alloys. Its role in the automotive industry for lightweight vehicle components will likely expand. Nevertheless, the reliance on this material mandates a constant evaluation of production methods. Improving sustainability should remain a focus as industries look for greener alternatives. As demand grows, addressing environmental impacts will be crucial for future production.

Ferro Silicon Manganese (FeSiMn) is a critical alloy in steel production. It enhances the strength and quality of steel. This alloy consists of iron, silicon, and manganese. It's used to improve hardness and reduce brittleness in steel. According to a market report by Research and Markets, the ferroalloys market is expected to reach USD 20 billion by 2026. This shows the growing importance of ferro alloys like Ferro Silicon Manganese.

The major applications of FeSiMn are seen in various steel grades. For instance, it is a key ingredient in producing high-strength low-alloy (HSLA) steel. This type of steel is crucial for construction and automotive industries. It improves ductility and tensile strength. Industry data reveals that around 80% of FeSiMn produced is used in steel manufacturing. The demand for durable steel products continues to rise, especially in emerging markets.

Tip: When considering alloys for steel production, think about the specific requirements for your application. Always ensure you have the right balance of elements in your alloys.

The journey of using FeSiMn is not without challenges. Maintaining the desired chemical composition can be tricky. Small variations can lead to significant performance issues in steel products. Regular quality checks are essential for achieving the best results. Always reflect on the implications of your material choices in production.

Ferro Silicon Manganese (FeSiMn) is poised for significant growth by 2026. Industries are adapting to its use in various applications. The steel production sector accounts for a major portion of its consumption. In 2020, reports indicated that FeSiMn contributed to nearly 45% of manganese’s overall usage in the steelmaking process, enhancing strength and durability.

Emerging industries are tapping into Ferro Silicon Manganese's potential. The electric vehicle sector is a notable example. Demand for lightweight, strong materials is crucial as automakers innovate. A recent study predicted that FeSiMn demand in EV manufacturing could rise by 35% by 2026. This shift marks a critical transition toward more sustainable and efficient production methods.

Furthermore, the renewable energy sector is increasingly looking at Ferro Silicon Manganese. Wind turbines and solar panels require resilient materials, and FeSiMn fits the bill. Analysts project that by 2026, its usage in renewable energy applications will rise by 20%. However, challenges remain, such as the need for improved recycling methods to maintain sustainability in production. The journey is not linear, and industries must address these hurdles to realize the full potential of Ferro Silicon Manganese.

Ferro silicon manganese is an alloy that combines iron, silicon, and manganese. Its popularity is rising due to its versatility in various industries. By 2026, its demand is projected to increase significantly. According to recent market analyses, the global ferro silicon manganese market is expected to grow at a CAGR of around 5.2% from 2023 to 2026.

Key industries driving the demand include steel manufacturing and foundry processes. For instance, in steel production, ferro silicon manganese enhances strength and durability. This alloy helps improve the overall quality of steel, making it an integral part of modern construction. Additionally, the automotive sector relies heavily on high-quality steel for vehicle parts, indicating a strong potential market for ferro silicon manganese.

However, challenges persist. Sourcing raw materials can be inconsistent, impacting production. Moreover, environmental concerns regarding mining practices raise questions about sustainability in the industry. Stakeholders must navigate these issues while maintaining growth. Addressing these areas will be critical as the market evolves in the coming years.

| Use | Description | Market Share (%) | Growth Rate (CAGR 2021-2026) |

|---|---|---|---|

| Steel Production | Used as a deoxidizer and alloying agent to improve steel quality. | 45% | 5.5% |

| Metal Alloys | Alloying agent in the production of various metal alloys. | 30% | 6.0% |

| Cast Iron | Enhances performance characteristics of cast iron products. | 15% | 4.0% |

| Other Applications | Used in various applications including batteries, welding rods, etc. | 10% | 7.0% |