Leave Your Message

In recent years, the semiconductor industry has witnessed a remarkable transformation driven by advancements in high-temperature processing technologies. One critical component at the forefront of this evolution is the Silicon Carbide Crucible, integral for melting and processing materials at extreme temperatures. According to a recent market analysis by Grand View Research, the global Silicon Carbide market is projected to reach USD 6.4 billion by 2030, growing at a CAGR of 17.9%. This growth is fueled by the increasing demand for efficient power electronics and high-performance applications across various sectors. As manufacturers seek to enhance their production techniques and improve material purity, the role of Silicon Carbide Crucibles becomes increasingly vital, offering superior thermal conductivity, chemical resistance, and durability under high-stress conditions. In this blog, we will explore the future of Silicon Carbide Crucibles and their transformative impact on high-temperature processing, presenting innovative solutions that meet the industry's evolving needs.

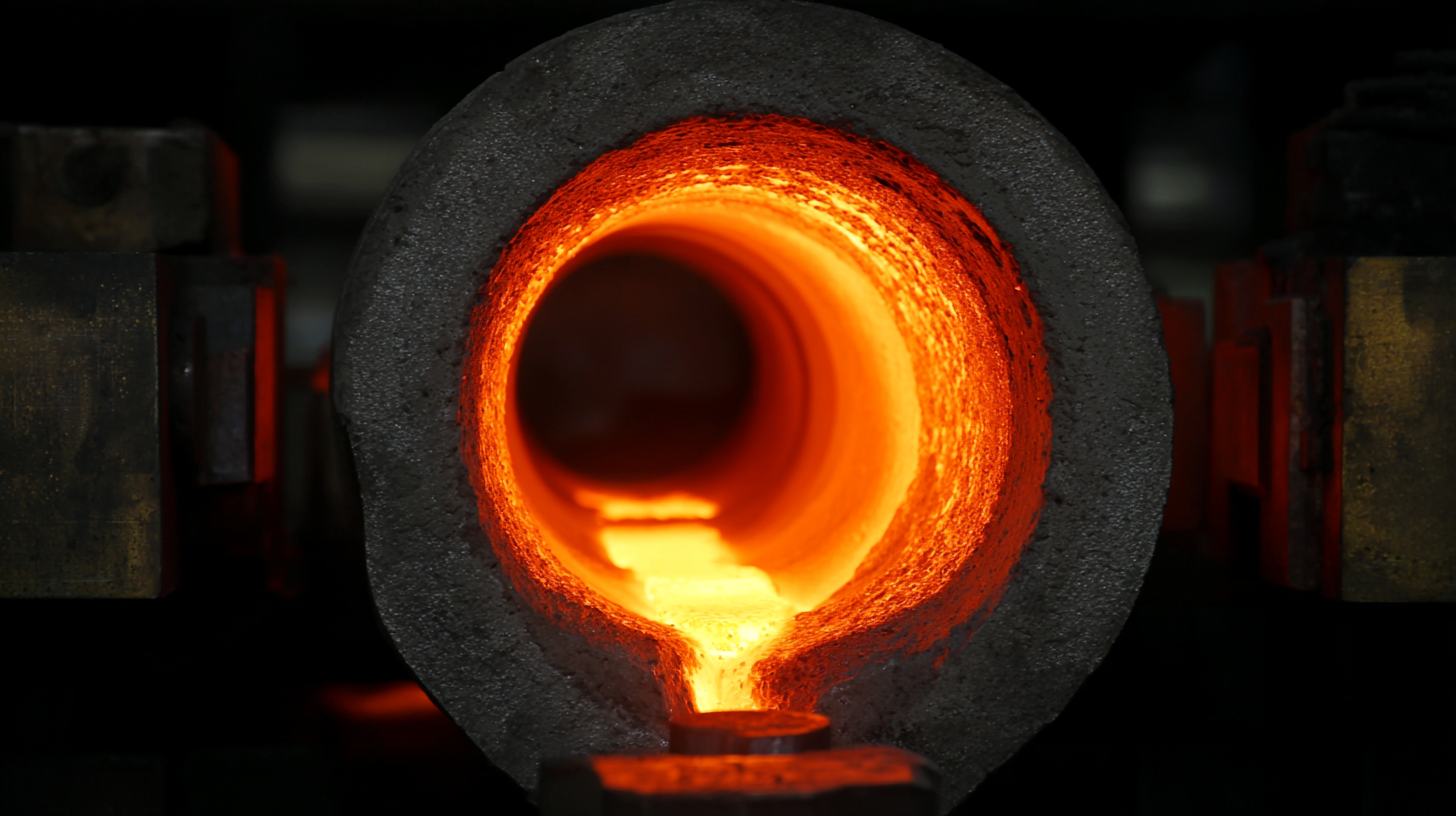

Silicon carbide crucibles are revolutionizing high-temperature processing with their exceptional thermal properties and durability. These crucibles can withstand extreme temperatures without degrading, making them ideal for applications in metallurgy, ceramics, and semiconductor industries. Their ability to maintain structural integrity under such conditions not only enhances productivity but also improves the quality of the materials being processed.

Tip: When selecting silicon carbide crucibles, consider the specific temperature range of your application. This will ensure optimal performance and longevity of the crucible.

Additionally, silicon carbide crucibles exhibit excellent resistance to thermal shock and chemical corrosion. This quality allows them to handle rapid temperature fluctuations and exposure to reactive substances without compromising their integrity. As industries continue to seek efficient materials that can withstand harsh processing environments, silicon carbide crucibles emerge as a leading choice.

Tip: Regularly inspect your crucibles for signs of wear and tear. Proper maintenance can significantly extend their lifespan and effectiveness in high-temperature applications.

Innovative manufacturing techniques are at the forefront of transforming

silicon carbide (SiC) crucibles, vital for high-temperature processing applications.

The adoption of advanced methods, such as the synthesis of silicon carbide whiskers through the stacking method, showcases the industry's push towards

improved material properties and efficiency. Recent reports indicate that the demand for SiC materials is rising dramatically, driven by their

suitability for extreme environments.

Data from industry analyses reveal that processing resource requirements are increasing in mineral extractive industries, correlating with a

decline in ore grades, which emphasizes the need for more resilient materials like SiC.

Tip: When exploring new

manufacturing techniques, consider investing in ultra-precision machining technologies.

This approach not only enhances the quality of processed silicon carbide single crystals but also streamlines the overall production process,

reducing waste and increasing output.

Furthermore, the significant investment in manufacturing and R&D within the UK, amounting to £360 million,

underlines the critical role of innovative materials in boosting competitive manufacturing capabilities. This movement is mirrored globally, with

initiatives like the establishment of fully integrated SiC facilities in Italy, paving the way

for localized production and reduced supply chain dependencies.

Tip: Staying informed about global advancements

and local investment opportunities can provide valuable insights into leveraging manufacturing capabilities effectively.

Silicon carbide (SiC) crucibles are emerging as a game-changing alternative to traditional crucible materials, particularly in high-temperature processing environments. Unlike conventional materials such as graphite and alumina, silicon carbide offers remarkable thermal stability and strength at extreme temperatures. This property makes SiC crucibles ideal for industries dealing with molten metals and advanced materials. The ability of silicon carbide to retain its structural integrity under relentless thermal stress not only enhances the efficiency of high-temperature processes but also extends the lifespan of the crucibles, resulting in reduced operational costs.

Silicon carbide (SiC) crucibles are emerging as a game-changing alternative to traditional crucible materials, particularly in high-temperature processing environments. Unlike conventional materials such as graphite and alumina, silicon carbide offers remarkable thermal stability and strength at extreme temperatures. This property makes SiC crucibles ideal for industries dealing with molten metals and advanced materials. The ability of silicon carbide to retain its structural integrity under relentless thermal stress not only enhances the efficiency of high-temperature processes but also extends the lifespan of the crucibles, resulting in reduced operational costs.

Moreover, silicon carbide boasts superior resistance to chemical reactions that can commonly occur during high-temperature operations. Traditional crucibles often suffer from degradation due to interactions with corrosive materials, leading to contamination and compromised material integrity. In contrast, SiC's exceptional chemical inertness minimizes such risks, enabling cleaner processing and higher quality end products. As industries continue to seek materials that can withstand extreme conditions while maintaining performance, the shift towards silicon carbide crucibles is likely to accelerate, paving the way for more advanced manufacturing techniques and applications.

As the demand for high-performance materials continues to grow, the production of silicon carbide crucibles is evolving to meet both industrial needs and environmental concerns. Sustainable practices in silicon carbide crucible production are becoming increasingly important, as manufacturers seek to reduce their carbon footprint and minimize waste. By integrating advanced recycling methods and energy-efficient technologies, producers can lower resource consumption and ensure a more sustainable lifecycle for these essential tools in high-temperature processing.

Innovations in material sourcing are also contributing to sustainability within the industry. Utilizing recycled silicon carbide not only reduces the need for virgin materials but also helps to cut down on energy-intensive extraction processes. Furthermore, manufacturers are embracing cleaner production techniques, such as the adoption of renewable energy sources in their operations. This shift towards eco-friendly practices is setting a new standard for the industry, making silicon carbide crucible production not only more efficient but also more aligned with global sustainability goals. As these trends continue, the future of silicon carbide crucibles will be shaped by a commitment to responsible production that benefits both businesses and the planet.

The emergence of silicon carbide (SiC) crucibles is set to revolutionize high-temperature processing across various industries. With the global SiC market expected to grow from $1.2 billion in 2021 to $5.2 billion by 2026, driven by its exceptional thermal conductivity and strength, SiC crucibles are increasingly being embraced in sectors like semiconductor manufacturing and advanced material processing. These crucibles not only withstand extreme temperatures but also enhance the efficiency of processes, making them essential in the production of high-quality silicon wafers and other materials.

In particular, advancements in SiC crystal growth technology, including the recent achievement of 8-inch wafers, are opening new avenues for innovation. As manufacturers like GlobalWafers plan to ramp up SiC production significantly by 2025, the versatility of SiC crucibles is being recognized in applications ranging from power electronics to renewable energy systems. Their capability to operate effectively in harsh environments makes them a pivotal component in emerging technologies such as electric vehicles and solar energy systems, further accelerating the transition to sustainable solutions. As these technologies continue to evolve, the strategic implementation of SiC crucibles will play a critical role in meeting both performance and environmental goals.