Leave Your Message

In the evolving landscape of industrial abrasives, the importance of selecting the right material for specific applications cannot be overstated. Black Silicon Carbide (SiC), a critical component in advanced manufacturing, has gained significant traction due to its superior hardness and thermal conductivity, making it ideal for applications ranging from grinding to cutting. According to the latest market analysis by MarketsandMarkets, the black silicon carbide market is expected to witness a compound annual growth rate (CAGR) of 4.9% from 2021 to 2026, highlighting its growing relevance in various sectors.

Industry expert Dr. Richard Thompson, a noted material scientist at the Advanced Abrasives Research Institute, emphasizes, "The choice of Black Silicon Carbide not only enhances operational efficiency but also improves product quality in machining processes." As manufacturers increasingly seek materials that can offer both performance and cost-effectiveness, understanding the unique properties and applications of Black Silicon Carbide becomes paramount. This guide will assist you in navigating the complexities of this versatile material to meet your specific needs effectively, ensuring you make informed decisions in your procurement strategy.

Black silicon carbide (SiC) is renowned for its exceptional hardness and thermal conductivity, making it a favored choice in various industries. With a Mohs hardness of 9.2, it ranks just below diamond, rendering it ideal for use in abrasive applications such as grinding and polishing. According to a report by Research and Markets, the global market for silicon carbide is expected to reach $4.5 billion by 2025, driven by its growing application in the automotive and electronics sectors. This increasing demand highlights the material's resilience and effectiveness in high-temperature environments, where conventional materials may fail.

In addition to its mechanical properties, black silicon carbide exhibits excellent chemical resistance, allowing it to withstand harsh conditions found in many industrial processes. Its unique structure also enhances its thermal stability, making it suitable for use in heating elements and other high-performance applications. A market analysis published by MarketsandMarkets indicates that the demand for black silicon carbide, particularly in the manufacturing of semiconductor devices, is expected to grow significantly, further solidifying its position as a critical material for advanced technologies. Understanding these properties and their implications is crucial for businesses seeking to leverage black silicon carbide to optimize their operations and product offerings.

| Property | Value | Applications |

|---|---|---|

| Hardness | 9.5 Mohs | Abrasives, cutting tools |

| Thermal Conductivity | 120 W/m·K | Heat sinks, electronics |

| Density | 3.21 g/cm³ | Refractories, ceramics |

| Melting Point | 2,700 °C | High-temperature applications |

| Electrical Conductivity | Low | Insulation in electronics |

| Chemical Stability | High | Corrosive environments |

When choosing the best black silicon carbide for your needs, it's essential to consider several key factors that can influence its effectiveness and suitability for various applications. First, assess the purity and grain size of the silicon carbide, as higher purity levels and smaller grain sizes typically enhance performance in abrasive and refractory applications. According to recent industry reports, the global silicon carbide market is expected to show significant growth, increasing from $886.2 million in 2024 to approximately $8.41 billion by 2032. This expansion indicates a rising demand for high-quality materials, underscoring the importance of selecting the right type of black silicon carbide that meets your specific requirements.

Another crucial factor to consider is the application area of the silicon carbide. Different industries may require variations in hardness, thermal conductivity, and chemical stability. For instance, the market analysis highlights that the silicon carbide fiber market was valued at $712.4 million in 2023, reflecting the material's versatility and its increasing adoption in sectors like aerospace, automotive, and electronics. Therefore, identifying the application-focused specifications of black silicon carbide can help you make an informed decision, ensuring that you select a product that aligns with your operational needs and performance expectations.

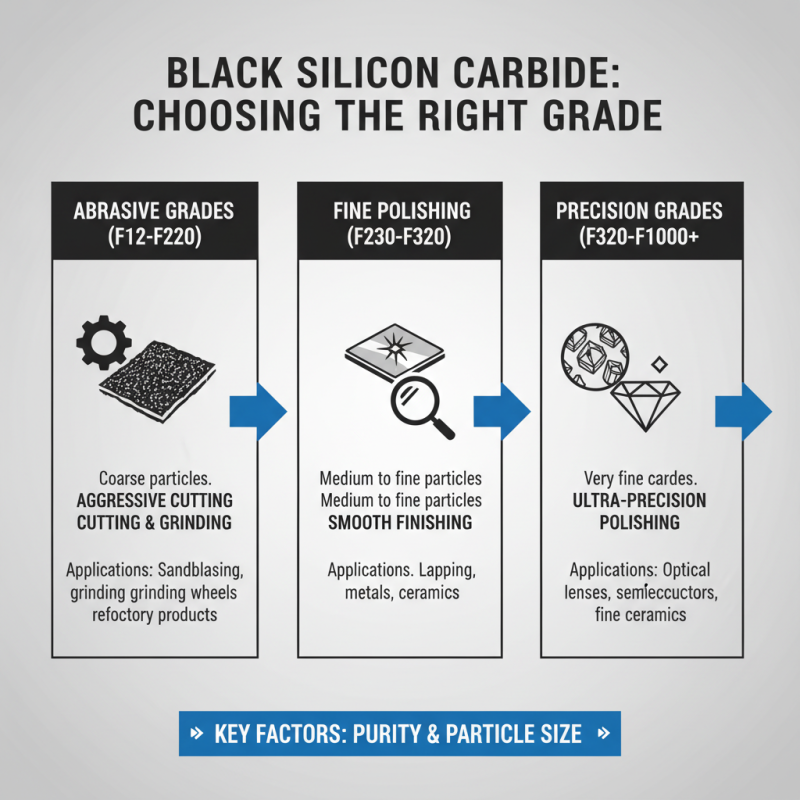

When selecting the best black silicon carbide for your needs, understanding the different grades available is crucial. Black silicon carbide is classified based on its purity and particle size, which directly affect its performance in various applications. The main grades typically include F12-F220, which are designated for abrasive applications, and microgrits like F230 and F1000 used in finer polishing processes. Higher grades, such as F320 and up, exhibit exceptional hardness and are ideal for precision grinding and polishing tasks.

Additionally, each grade offers distinct characteristics suited for specific uses. For instance, lower-grade black silicon carbide is often utilized for coarse cutting and grinding, while higher-grade options are preferred for meticulous finishing work in industries like electronics and automotive. When making your choice, consider factors like the desired finish quality, substrate material, and the operational conditions of your project. This tailored approach will enable you to effectively match the right grade of black silicon carbide to your unique requirements.

When evaluating suppliers for black silicon carbide, quality assurance and certifications play a critical role in ensuring that the materials meet industry standards and specifications. Businesses should focus on supplier identification and evaluation services that can provide insights into a supplier's reliability in terms of quality, cost, and delivery capabilities. This process often involves comprehensive audits, which can help identify potential risks and areas of improvement in a supplier's performance. For example, regulations regarding purchasing controls are essential for manufacturers, emphasizing the need for compliant and trustworthy suppliers.

Furthermore, certifications such as those related to aerospace or food safety serve as indicators of a supplier's commitment to maintaining high standards. A supplier that has achieved rigorous certifications demonstrates adherence to strict guidelines, which can significantly enhance trust and cooperation. Companies should pursue suppliers that not only fulfill basic operational requirements but also exhibit a commitment to ongoing quality improvement through proper certifications, thereby ensuring that they receive reliable and high-quality black silicon carbide tailored to their specific needs.

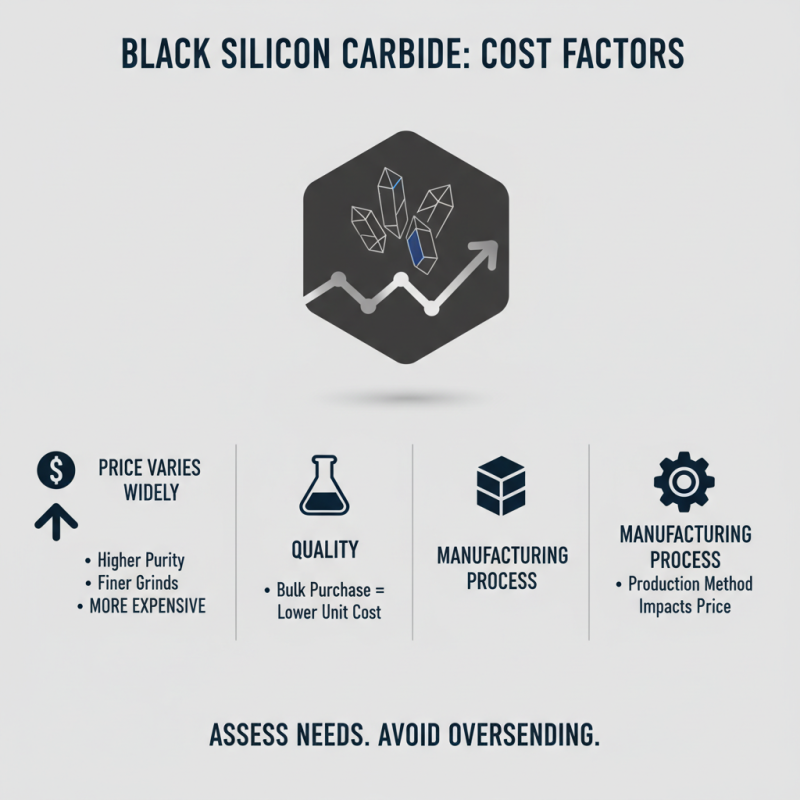

When considering the purchase of black silicon carbide, cost is a critical factor that can significantly influence your decision. The price of black silicon carbide can vary widely based on several factors such as quality, quantity, and manufacturing processes. Generally, higher purity and finer grades tend to be more expensive, so it is important to assess your specific application needs to avoid overspending.

**Tips:** Before making a purchase, compare prices from multiple suppliers to ensure you are getting a competitive rate. Also, consider bulk buying options if you require large quantities, as many suppliers offer discounts for larger orders.

Additionally, consider the long-term benefits of investing in higher-quality black silicon carbide. While the initial price may be higher, superior materials can lead to improved performance and decreased replacement costs in the long run. Always check for certifications or reviews regarding the supplier's reputation to ensure that the product meets industry standards.

**Tips:** Look for customer testimonials or third-party evaluations to substantiate the quality of the black silicon carbide. Establishing a relationship with a reliable supplier can also help you get better pricing and support for future needs.