Leave Your Message

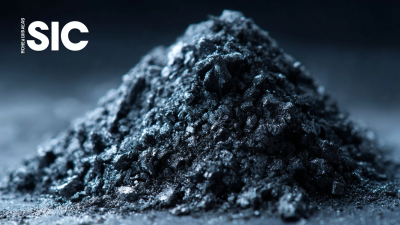

In recent years, the demand for advanced materials in industrial applications has surged, driving the exploration of innovative solutions like Silicon Carbide Ceramic. This remarkable material exhibits exceptional thermal conductivity, which is crucial for enhancing performance and efficiency in various sectors, including electronics, automotive, and energy.

According to a report by ResearchAndMarkets, the global Silicon Carbide market is projected to grow at a compound annual growth rate (CAGR) of 15.4% from 2020 to 2025, highlighting its increasing importance in modern manufacturing processes. The unique properties of Silicon Carbide Ceramic, such as high-temperature resistance and mechanical strength, make it an ideal choice for environments that demand superior thermal management.

As industries strive for improved operational efficiency and sustainability, leveraging the capabilities of Silicon Carbide Ceramic could lead to groundbreaking advancements in thermal conductivity, directly impacting productivity and resource optimization.

Silicon carbide (SiC) ceramic is gaining attention in industrial applications due to its superior thermal conductivity and mechanical strength. Understanding its unique properties is crucial for effective thermal management in various sectors. SiC ceramics exhibit high thermal conductivity, allowing for efficient heat dissipation, which is essential in high-performance environments like semiconductor manufacturing and aerospace. Their ability to withstand high temperatures without degradation makes them ideal for applications where conventional materials might fail.

Additionally, the thermal expansion characteristics of silicon carbide ceramics are favorable, minimizing thermal stress and contributing to the longevity of components. These materials possess a low coefficient of thermal expansion, which reduces the risk of cracking under thermal cycles. Furthermore, SiC ceramics are chemically resistant and do not corrode easily, making them suitable for harsh environments. By leveraging these intrinsic properties, industries can enhance their thermal management systems, ensuring better performance and reliability in critical applications.

Thermal conductivity is a crucial factor in determining the efficiency of industrial processes. In environments where heat dissipation plays a vital role, materials with high thermal conductivity, such as silicon carbide ceramic, can make a substantial difference. The ability of silicon carbide to transfer heat effectively minimizes the risk of overheating and ensures optimal operating temperatures, which is essential for maintaining the performance of machinery and equipment.

By leveraging silicon carbide ceramics, industries can enhance their operational efficiency. These materials not only provide superior thermal conduction but also exhibit remarkable durability and resistance to chemical corrosion. This means that using silicon carbide in applications such as heat exchangers, furnace linings, and electronic components can lead to longer service life, reduced maintenance costs, and improved overall productivity. As industries continue to seek ways to optimize their processes, integrating advanced materials that promote better thermal management will be a strategic advantage.

Silicon carbide (SiC) has emerged as a game-changer in thermal management, particularly when compared to traditional materials like aluminum and copper. According to a report from ResearchAndMarkets, SiC exhibits thermal conductivity ranging from 120 to 200 W/m·K, significantly outpacing aluminum, which has a thermal conductivity of approximately 205 W/m·K, and copper at around 401 W/m·K. While copper is often favored for its superior thermal conductivity, SiC's lightweight nature and higher thermal stability make it an attractive alternative for high-performance industrial applications where weight and integrity under extreme conditions are crucial.

Moreover, the advantages of silicon carbide extend beyond just thermal conductivity. A comparative study by the Materials Research Society highlights that SiC has a much higher thermal shock resistance due to its robust chemical structure, making it more suitable for environments subject to rapid temperature fluctuations. In contrast, traditional materials can suffer from thermal fatigue and failure, leading to increased downtime and maintenance costs. The use of SiC can thus enhance system reliability while significantly improving heat dissipation efficiency, making it a worthy consideration in industries such as aerospace, automotive, and power electronics.

Silicon carbide ceramic is making significant strides in various industrial applications due to its superior thermal conductivity properties. One notable example is in the automotive industry, where manufacturers are increasingly using silicon carbide ceramics in heat exchangers and engine components. These ceramics enhance thermal efficiency, allowing engines to operate at higher temperatures without compromising performance. As a result, vehicles are not only becoming more fuel-efficient but also experiencing improved overall durability and reduced emissions.

Another industry benefiting from silicon carbide ceramic is the semiconductor sector. As devices become smaller and more powerful, the need for efficient thermal management systems is paramount. Silicon carbide ceramics are implemented in substrates and insulators, facilitating heat dissipation in high-performance electronic devices. This leads to greater reliability and longevity of semiconductor components, crucial for everything from consumer electronics to aerospace applications. The integration of silicon carbide ceramic is paving the way for innovation, ensuring that industries can meet the growing demands for efficiency and performance in an increasingly competitive market.

Silicon carbide (SiC) has emerged as a game-changer in industrial thermal solutions, driven by its superior thermal conductivity and mechanical strength. Recent industry reports forecast that the global silicon carbide market will reach $4.3 billion by 2026, growing at a compound annual growth rate (CAGR) of 16.6% from 2021. This growth is largely fueled by innovations in SiC technologies, which are enabling enhanced performance in high-temperature applications, such as automotive power devices, aerospace components, and semiconductor electronics. The ability of SiC to efficiently dissipate heat not only enhances performance but also extends the lifespan of critical industrial equipment.

Moreover, ongoing research and development are focusing on the integration of advanced manufacturing techniques to produce SiC ceramics with tailored thermal properties. For instance, the use of additive manufacturing has shown promise in creating complex shapes with optimized heat transfer capabilities. A recent study published in the Journal of Materials Science highlighted that the thermal conductivity of SiC ceramics can exceed 120 W/m·K, outperforming traditional materials like aluminum oxide. As industries seek to optimize their thermal management systems, the innovations in silicon carbide technologies will undoubtedly play a pivotal role in shaping the future of industrial thermal solutions.