Leave Your Message

Metallic Silicon is an essential material in various industries. Its versatility makes it valuable for many applications. This compound plays a significant role in the production of silicone, semiconductors, and solar panels. Each of these uses highlights its unique properties.

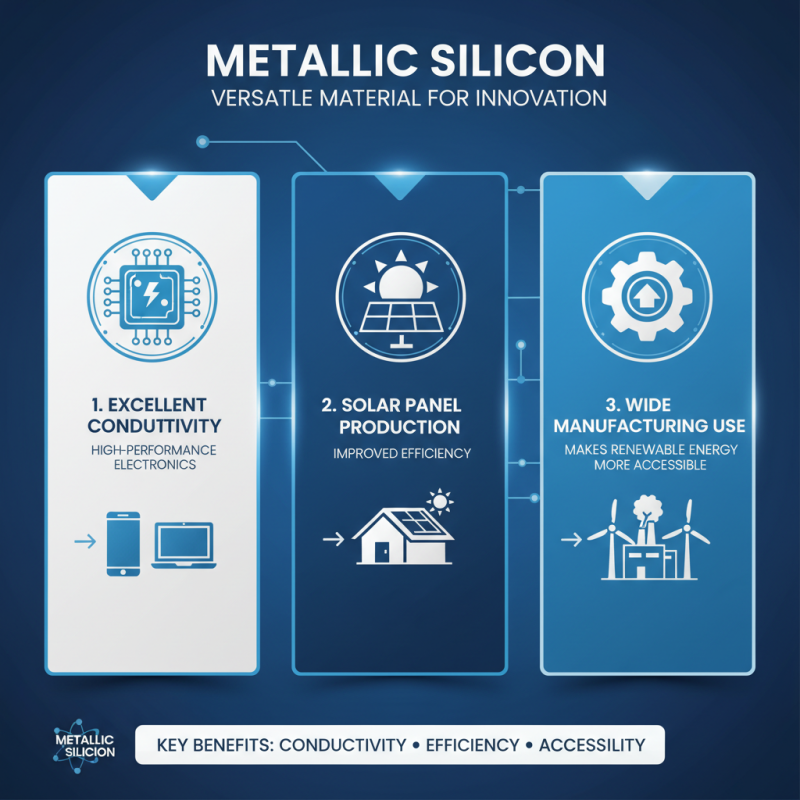

In electronics, Metallic Silicon serves as a critical component. It provides excellent conductivity, making it ideal for chips and transistors. The solar industry also benefits greatly from this material. Solar cells rely on its ability to convert sunlight into electricity. However, the production process raises questions about sustainability.

While Metallic Silicon has many advantages, there are challenges. The extraction and refinement can impact the environment. It's crucial to find a balance between usage and ecological responsibility. As industries evolve, the role of Metallic Silicon must be continually reassessed.

Metallic silicon is a form of silicon known for its metallic luster. It has a variety of applications across different industries. Primarily, it is used in the production of aluminum alloys. Adding silicon enhances the strength and quality of these materials. Moreover, metallic silicon plays a crucial role in making semiconductors. Its excellent electrical conductivity makes it ideal for electronic devices.

When using metallic silicon, consider its purity level. High-purity silicon is vital for electronic components. Impurities can significantly affect the performance. Always check the specifications before purchasing.

Tips: Ensure you store metallic silicon in a dry place. This will prevent oxidation and maintain its properties. Additionally, handling should be done with care. Dust and powder from silicon can be harmful if inhaled. Be mindful of safety protocols while working with it.

Metallic silicon possesses properties that make it invaluable across several industries. Its high electrical conductivity allows it to be used effectively in electronics. According to a recent report by Markets and Markets, the global demand for metallic silicon is projected to reach 3 million tons by 2025, driven by its extensive applications in solar cells and semiconductors. The inherent ability of metallic silicon to withstand high temperatures adds to its utility in the metallurgical sector.

One of its key properties is its resistance to oxidation, which is crucial for numerous applications. Silicon is also resistant to corrosion, making it valuable in chemical processing. However, the production of metallic silicon can be energy-intensive, raising concerns over sustainability. Reports suggest that up to 50% of the energy used in silicon production comes from non-renewable sources. This raises a question about the environmental impact versus its benefits in modern technology. Silicon's role in innovative energy solutions needs careful reassessment moving forward.

Metallic silicon is a crucial material in various industries. One of its primary applications is in the production of semiconductors. These tiny components are essential for electronic devices. Without them, our smartphones and computers wouldn’t function. Silicon's high electrical conductivity makes it ideal for this purpose.

Another significant use of metallic silicon is in the manufacturing of solar panels. Solar energy is becoming increasingly important. The efficiency of solar cells largely depends on the quality of silicon used. Higher purity silicon can convert sunlight into energy more effectively. However, the process to obtain high-purity silicon is complex and requires substantial energy.

Alloy production is yet another area where metallic silicon shines. It enhances the mechanical properties of aluminum alloys. This is key for lightweight applications in the automotive and aerospace sectors. Yet, the integration of metallic silicon in alloys does not always yield the desired results. Engineers must continuously refine their methods and materials to overcome these challenges and improve performance.

| Application | Description | Benefits |

|---|---|---|

| Semiconductors | Used in the production of silicon wafers for electronic components. | High conductivity, essential for modern electronic devices. |

| Solar Cells | Key component in photovoltaic cells for converting solar energy into electricity. | Increases efficiency and longevity of solar panels. |

| Alloys | Used in various metal alloys to enhance mechanical properties. | Improves strength, durability, and resistance to oxidation. |

| Chemicals | Used in the production of silicones and silanes. | Versatile compounds with applications in sealants, lubricants, and coatings. |

| Glass Manufacturing | Used as an additive in the production of glass. | Enhances transparency and strength of glass products. |

Metallic silicon is a versatile material widely used in various manufacturing processes. One of its primary benefits is its excellent conductivity. This property allows manufacturers to create high-performance electronics. In solar panel production, metallic silicon plays a crucial role. It helps improve efficiency, making renewable energy more accessible.

Another significant advantage is its ability to withstand high temperatures. This characteristic is essential in metal alloys, where silicon enhances strength and durability. Industries often rely on these enhanced materials for their reliability. However, it's important to note that not all metallic silicon meets the same quality standards. Quality control remains a challenge in some manufacturing sectors.

Additionally, metallic silicon is crucial in the automotive industry. Its incorporation into components improves performance and reduces weight. This innovation leads to better fuel efficiency. Nonetheless, the environmental impact of extracting and processing silicon cannot be overlooked. As industries strive for sustainability, we must reflect on our methods. Balancing progress and environmental responsibility is key.

Metallic silicon is gaining attention for its potential in various innovative applications. One emerging trend is its role in renewable energy. As the world shifts to sustainable sources, metallic silicon helps improve the efficiency of solar panels. Higher silicon purity leads to increased energy conversion rates, benefiting both manufacturers and consumers. Research indicates that better silicon materials can enhance output by up to 20%.

Another area of innovation involves the use of metallic silicon in electronics. With the growth of electric vehicles, silicon-based semiconductors are becoming crucial. They can handle higher power levels and temperatures compared to traditional materials. This shift could revolutionize how electric vehicles operate, but challenges remain. Ensuring long-term stability and performance is still a concern.

Metallic silicon is also being explored in the production of advanced batteries. The potential for silicon anodes to deliver larger capacities is significant. However, the expansion and contraction during charging cycles can lead to mechanical issues. Ongoing research aims to overcome these limitations and enhance durability. The future trends in metallic silicon usage show promise but require careful consideration and innovation to fully realize their benefits.