Leave Your Message

Sic Silicon Carbide is a compound that has gained significant attention in recent years. Its unique properties make it vital for various industries. From electronics to automotive, Sic Silicon Carbide plays a crucial role in enhancing performance and efficiency.

This material is known for its exceptional thermal conductivity and high-temperature resistance. These traits allow it to perform well in harsh environments. Many companies are turning to Sic Silicon Carbide for next-generation applications, emphasizing its importance in modern technology.

While the benefits are clear, there are still challenges to consider. The manufacturing process can be complex and costly. Companies must navigate these obstacles to fully harness the potential of Sic Silicon Carbide. As research continues, it is crucial to evaluate how we can improve its production and application methods.

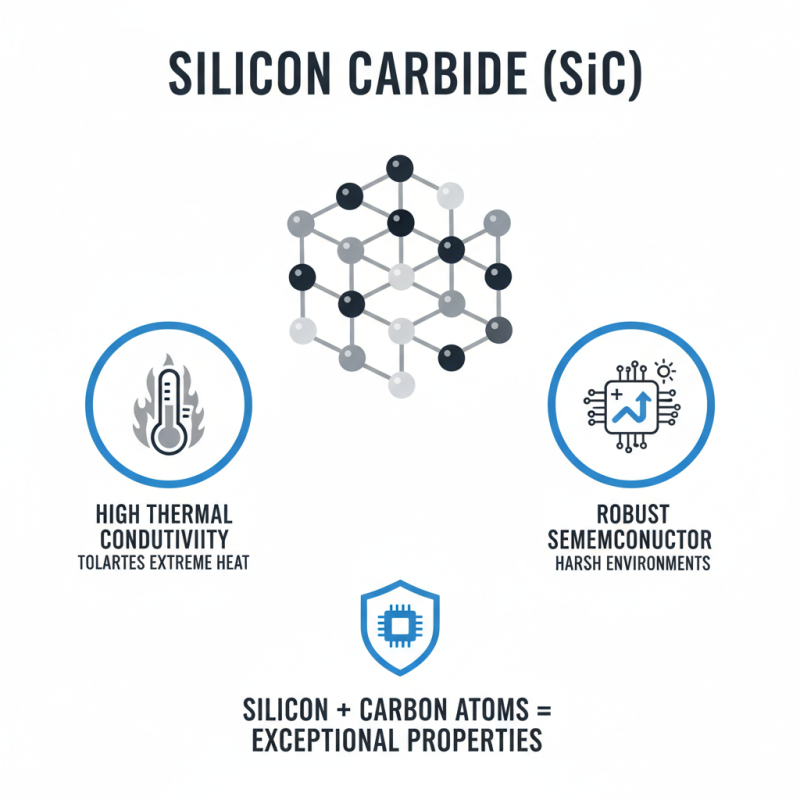

Silicon Carbide, or SiC, stands out as a unique semiconductor material. It is composed of silicon and carbon atoms. This combination results in exceptional properties. SiC is notable for its high thermal conductivity. It handles high temperatures very well, making it suitable for harsh environments.

In industries, SiC plays a crucial role. It is used in power electronics and high-voltage devices. These applications benefit from SiC's ability to operate efficiently at elevated temperatures. It reduces the energy loss typically seen in traditional silicon devices. This energy efficiency can theoretically transform industries, driving technologies forward.

Despite its benefits, SiC is not without challenges. The production of SiC substrates can be complex and costly. There are ongoing discussions about improving these processes. Optimizing the use of SiC requires careful consideration of its manufacturing hurdles. Reflecting on such aspects can drive innovation and better solutions in the future.

Silicon carbide (SiC) is a semiconductor known for its remarkable properties. It has a high thermal conductivity, great electrical conductivity, and outstanding mechanical strength. This means it can withstand extreme temperatures and high power levels. These characteristics make SiC ideal for various applications, particularly in power electronics.

One unique property of SiC is its ability to operate under high voltages. This quality allows devices using SiC to be smaller and more efficient compared to traditional silicon components. SiC devices can handle larger amounts of power while generating less heat, resulting in longer-lasting products. However, it’s worth noting that working with SiC can be challenging due to its hardness. Specialized equipment is required to process it, which can lead to higher manufacturing costs.

Despite these challenges, the benefits of SiC are profound. Its use in electric vehicles, renewable energy, and industrial applications is expanding rapidly. As the demand for energy-efficient solutions grows, SiC's role becomes increasingly significant. There are still areas to explore and improve. Development in SiC technology is ongoing, revealing new potentials and innovations.

Silicon Carbide (SiC) is reshaping various industries. Its applications range from automotive to energy sectors. In electric vehicles, SiC improves efficiency and reduces energy loss. This material allows shorter charging times and increases range. Many manufacturers are exploring SiC for power electronics. The demand is growing rapidly, driven by the push for sustainable solutions.

In the renewable energy sector, SiC devices play a crucial role. They enhance the performance of solar inverters and wind turbines. SiC's thermal conductivity handles higher temperatures effectively. This leads to reliable operations in harsh environments. However, some challenges remain. The manufacturing process is complex and costly. Companies are still finding ways to optimize production.

Tips: When considering SiC for a project, assess cost versus long-term benefits. Test different designs to find optimal configurations. Don’t overlook the importance of thermal management in your applications. Always stay updated with emerging technologies to make informed choices. Embracing SiC can be transformative, yet be cautious about the investment. Balancing innovation with practicality is essential.

Silicon carbide (SiC) is a remarkable material in modern technology. Its high thermal conductivity and exceptional hardness make it vital for various applications. SiC is used in power electronics, such as transistors and diodes. These devices enhance efficiency in electric vehicles and renewable energy systems. Moreover, SiC is resistant to high temperatures, enabling its use in harsh environments.

Tips: When considering SiC for applications, think about the thermal management. A proper cooling system can boost the performance significantly.

In the semiconductor industry, SiC plays a crucial role. Compared to traditional silicon, SiC can handle higher voltages. This feature allows for smaller, lighter designs in electronic devices. Yet, fabricating SiC remains challenging. The technology is improving, but there are still hurdles. Researchers are working on better production methods to lower costs while improving quality.

Tips: Stay informed about advancements in SiC technology. New research may lead to innovative applications in your area.

The research surrounding silicon carbide (SiC) is rapidly evolving. Scientists are exploring its potential in various industries. SiC’s exceptional properties include high thermal conductivity and power efficiency. These qualities make it a game-changer in the semiconductor industry. The push for greener technologies has intensified its relevance.

Recent trends highlight SiC's role in electric vehicles. Its ability to reduce energy loss is crucial. Moreover, there's ongoing research into enhancing its production methods. Many scientists believe improving the quality and cost-effectiveness of SiC is essential. It remains a challenge, though. Current methods can be costly and complex. This invites further inquiry and innovation.

Innovative applications of SiC go beyond vehicles. Future developments may include renewable energy solutions. However, the pace of research can sometimes feel slow. Collaboration among researchers is vital. There’s much to learn from shared insights and failures. Exploring the limitations can lead to breakthroughs. Embracing imperfection in research may yield unexpected results in SiC advancements.