Leave Your Message

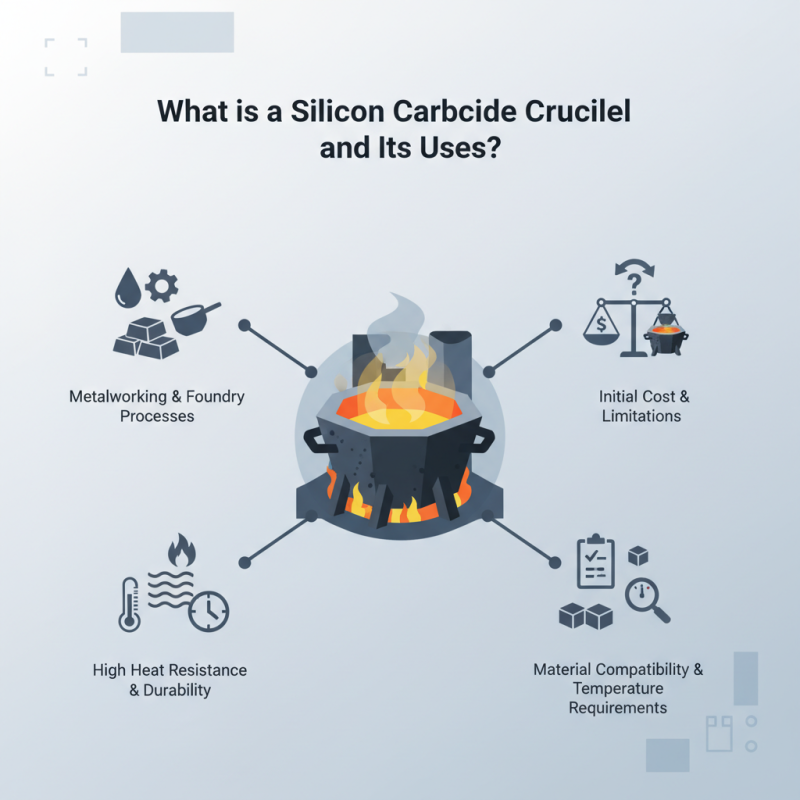

The Silicon Carbide Crucible is a vital tool in many industrial applications. Known for its high heat resistance, it can withstand extreme temperatures. This makes it ideal for melting metals and other materials.

Typically, a Silicon Carbide Crucible is used in metalworking and foundry processes. Its durability ensures longevity, even under harsh conditions. Many industries rely on these crucibles for their efficiency. However, they are not without limitations. The initial cost can be high, which may deter some users.

Understanding the full range of uses can illuminate their value. They are not universally perfect for every melting application. Users must carefully consider material compatibility and temperature requirements. Reflection on these factors can lead to better decision-making in choosing the right crucible.

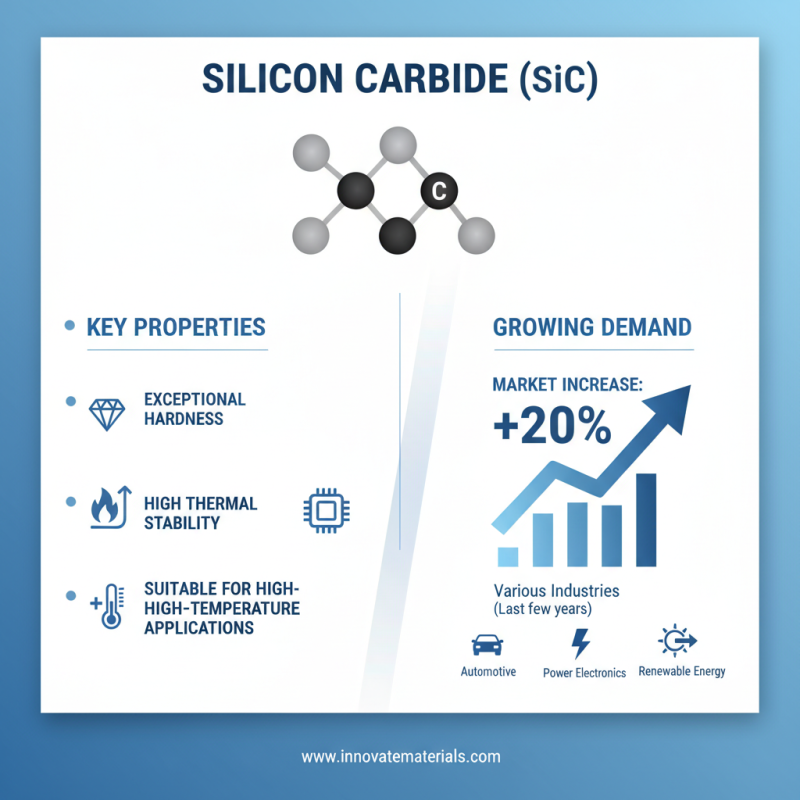

Silicon carbide (SiC) is a compound made of silicon and carbon. This material is known for its exceptional hardness and thermal stability. It has unique properties that make it suitable for high-temperature applications. According to market reports, the demand for silicon carbide in various industries has increased by over 20% in recent years.

SiC crucibles are popular in metallurgy and ceramics. They withstand extreme temperatures, often exceeding 1,600°C. Their ability to resist oxidation adds to their durability. Additionally, they are chemically inert, which prevents contamination. Industries like aluminum, iron, and steel extensively utilize these crucibles for melting metals. A recent study indicated that around 65% of metal casting processes now incorporate silicon carbide crucibles due to their efficiency.

Despite their advantages, SiC crucibles are not without challenges. They can be brittle, which makes handling difficult. Cracks may form if not managed carefully. This brittleness necessitates proper training for operators. Companies must invest in safety measures to minimize breakage. Evaluating the benefits against potential risks is crucial for effective utilization.

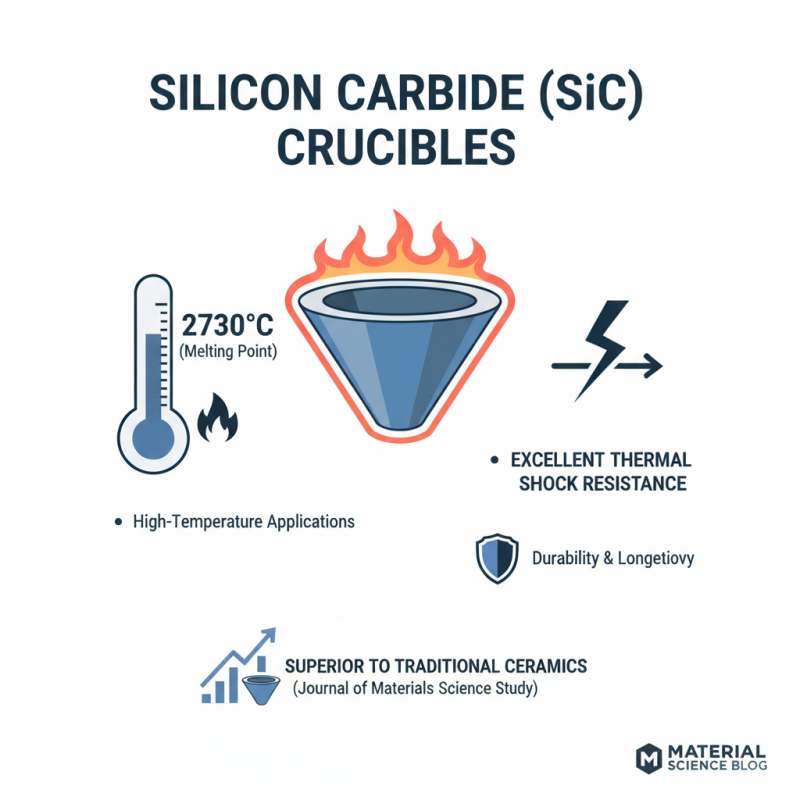

Silicon carbide (SiC) crucibles are essential in high-temperature applications due to their remarkable thermal stability and durability. SiC has a melting point of about 2,730°C, making it suitable for environments that reach extreme temperatures. The material exhibits excellent resistance to thermal shock, which is critical during rapid temperature changes in metal casting processes. In fact, a study published in the Journal of Materials Science indicates that SiC can withstand thermal cycling better than traditional ceramic materials.

In addition to their thermal properties, SiC crucibles display impressive chemical resistance. They can endure corrosive environments, especially when dealing with molten metals and alloys. This chemical stability reduces the risk of contamination in processes like semiconductor manufacturing. According to global market analysis, the demand for SiC materials in high-performance crucibles is projected to increase by 8% annually through 2025. This growth reflects industries' reliance on advanced materials for efficiency and reliability.

However, there are challenges. The manufacturing process of SiC crucibles is complex and often costly. Some users report difficulties in achieving the desired purity levels, which is crucial for certain applications. Improvements are necessary in production techniques to enhance the quality and affordability of SiC crucibles. Despite these hurdles, their unique properties continue to make them a popular choice for high-temperature processing.

Silicon carbide crucibles are essential tools in various industries. They offer excellent thermal resistance and durability. One common application is in metal casting. They can withstand extreme temperatures, making them ideal for molten metals. Whether for aluminum or copper, these crucibles provide reliable results.

Another significant use is in the production of ceramics. Silicon carbide's chemical stability enables it to handle high-kiln environments. Ceramics are often fired at high temperatures, and a silicon carbide crucible can endure that stress. As a result, the quality of the final product improves significantly.

Tips: Always check the crucible's compatibility with the material you plan to use. The wrong choice may lead to unwanted reactions. Keep in mind the size of the crucible. Larger crucibles can hold more material but may take longer to heat. It’s important to find the right balance for your needs.

Silicon carbide crucibles are revolutionizing the metalworking and foundry industries. One major advantage is their high thermal conductivity. Unlike traditional materials, silicon carbide can withstand higher temperatures without deforming. Research indicates it can endure up to 1,600 °C. This results in faster melting processes and better energy efficiency.

Another significant advantage is the material's resistance to chemical corrosion. Silicon carbide does not react with many metals during melting. This leads to fewer impurities, enhancing the quality of the final product. According to a study by Metal Casting, about 70% of defects are caused by crucible contamination. Using silicon carbide reduces this risk considerably, making it an excellent choice for precise applications.

Additionally, silicon carbide crucibles offer improved durability. They can last significantly longer than conventional graphite or clay-based options. Reports suggest they can last up to five times longer. However, they can be more expensive upfront. This cost can deter some smaller foundries. Nevertheless, the long-term savings in material costs and increased production justify the investment for many.

When choosing a silicon carbide crucible, focus on its material quality.

Silicon carbide is durable. It withstands high temperatures and resists thermal shock. This makes it suitable for metal casting and other applications. Look for crucibles that have a consistent thickness.

Uniformity can help prevent cracks and prolong usage.

Consider the size of the crucible.

It should match your operation needs. If it's too small, you may face overflow issues. A larger crucible means more material but can be cumbersome. Think about the shape as well. Certain designs can enhance material pouring and reduce waste.

Don't forget to assess the weight.

Heavier crucibles often offer better stability during high-temperature processes. However, they can be challenging to handle. Always review user feedback.

Sometimes, the best insights come from those in the field. Understanding their experiences can help avoid common pitfalls.