Leave Your Message

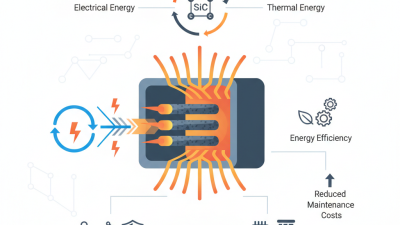

In recent years, the demand for efficient heating solutions has surged, driven by the need for energy conservation and sustainability across various industries. One of the pivotal advancements in this field is the Silicon Carbide Heating Element, which offers superior thermal efficiency and longevity compared to traditional materials. According to a report published by the International Energy Agency, industrial heat accounts for approximately 37% of total energy consumption, emphasizing the significance of implementing cutting-edge heating technologies that can minimize energy loss and improve operational efficiency.

Silicon carbide, a compound semiconductor, has demonstrated remarkable properties such as high thermal conductivity, resistance to oxidation, and the ability to withstand extreme temperatures. The World Semiconductor Trade Statistics projects that the global market for silicon carbide will grow significantly, with an estimated CAGR of 24% from 2021 to 2026. This establishment as a critical component in manufacturing processes—from metal processing to semiconductor industries—illustrates the importance of silicon carbide heating elements in promoting both operational efficacy and energy savings.

As industries increasingly seek innovative solutions to meet stringent energy regulations and reduce carbon footprints, the role of Silicon Carbide Heating Elements becomes even more crucial. Their capacity to operate at higher temperatures with improved energy efficiency not only enhances the productivity of manufacturing processes but also contributes to the overarching goal of sustainable industrial practices in a rapidly evolving market landscape.

Silicon carbide heating elements are increasingly recognized as a cornerstone of efficient heating solutions across various industries. These elements, known for their exceptional thermal conductivity and stability at high temperatures, can operate effectively in challenging environments, making them ideal for applications in metal processing, ceramics, and glass manufacturing. According to the International Journal of Applied Ceramic Technology, silicon carbide heating elements can achieve efficiencies of up to 90%, greatly outperforming traditional heating solutions like metal coils and wire-based systems.

One of the significant advantages of silicon carbide heating elements is their ability to provide uniform heat distribution. The high emissivity of silicon carbide ensures that heat is radiated evenly, reducing hot spots and maximizing heating efficiency. This uniformity is crucial in industrial applications where consistent temperature control can significantly affect product quality. Additionally, studies show that silicon carbide elements can endure temperatures exceeding 1600°C, enabling them to operate in extreme conditions without degradation.

Tips: When selecting heating elements for your application, consider the temperature range and environment. Silicon carbide is particularly beneficial in setups requiring rapid temperature changes or in harsh conditions. Furthermore, ensure that you assess the installation and maintenance requirements to optimize the longevity and efficiency of these heating elements. By leveraging the properties of silicon carbide, industries can achieve not only cost-effective solutions but also sustainable and reliable heating processes.

| Property | Silicon Carbide Heating Elements | Traditional Heating Elements |

|---|---|---|

| Material Composition | Silicon Carbide (SiC) | Metal alloys or ceramic |

| Maximum Operating Temperature | Up to 1600°C | Up to 1200°C |

| Energy Efficiency | Higher energy efficiency | Lower energy efficiency |

| Heat Transfer Rate | Fast and uniform | Slower and less uniform |

| Durability | Highly durable and resistant to thermal shock | Less durable and prone to thermal fatigue |

| Application Areas | Industrial heating, furnaces, and laboratories | Home appliances, low-temperature heating |

Silicon carbide (SiC) heating elements are increasingly recognized for their unique advantages in various heating applications. One of the primary benefits of silicon carbide is its

exceptional thermal conductivity, enabling efficient heat transfer and reducing energy consumption. This property allows for

faster heating rates and more uniform temperature distribution, which is critical in industrial processes and high-performance applications. Furthermore, silicon carbide can

withstand higher temperatures compared to traditional heating elements, making it ideal for environments requiring resilience and durability.

When choosing silicon carbide heating solutions, consider these tips to maximize efficiency: ensure proper installation to reduce heat loss, and maintain optimal air circulation around the

heating element. This can significantly enhance performance and prolong the lifespan of the heating components. Additionally, using advanced control systems

that monitor and adjust the heating parameters in real-time can further optimize energy usage.

Another key advantage of silicon carbide heating elements is their chemical stability. They are less prone to oxidation and degradation, meaning

they maintain performance over time even in harsh conditions. This durability translates to lower maintenance costs and longer operational life, making them a cost-effective choice in the

long run. For industries ranging from ceramics to metals processing, incorporating silicon carbide heating elements can lead to improved productivity and reduced operational downtime.

When comparing Silicon Carbide (SiC) heating elements to traditional heating elements, the differences in efficiency and performance become strikingly apparent. Traditional heating elements, often made from materials like nickel or stainless steel, tend to have lower thermal conductivity and slower response times. This results in longer heating periods and less effective temperature control, which can lead to wasted energy and higher operational costs. In contrast, SiC heating elements exhibit superior thermal conductivity, allowing for quicker heat-up times and more uniform temperature distribution across the heating surface. This efficiency translates into energy savings and more effective heating solutions for myriad applications.

Moreover, the durability of Silicon Carbide in extreme conditions further distinguishes it from conventional materials. Traditional elements may suffer from oxidation or degrade quickly when subjected to high temperatures or harsh environments, necessitating frequent replacements. Silicon Carbide, however, is known for its robust performance and resistance to thermal shock, significantly extending its lifespan. This durability not only reduces maintenance costs but also contributes to a more sustainable approach to heating solutions. Consequently, for industries seeking both efficiency and longevity in their heating systems, Silicon Carbide heating elements present a compelling alternative to traditional heating technologies.

Silicon carbide (SiC) heating elements have become increasingly vital in various industrial applications due to their robustness and efficiency. They are predominantly utilized in processes that require high temperatures, such as in furnaces, kilns, and laboratory processes. According to a report by Research and Markets, the global market for silicon carbide heating elements is projected to grow at a CAGR of approximately 7.5% over the next five years, indicating a rising acceptance in sectors such as semiconductor manufacturing, automotive, and aerospace.

In the semiconductor industry, SiC heating elements play a crucial role in the fabrication of electronic components. Their ability to withstand extreme temperatures and corrosive environments makes them ideal for processes such as diffusion and oxidation. For example, a study from the International Journal of Materials Science highlights that using SiC can enhance thermal efficiency by up to 30%, which translates to significant energy savings in manufacturing settings. Similarly, in the aerospace sector, SiC heating elements are employed during material processing, ensuring consistent performance under high-stress conditions, a critical factor for maintaining safety and reliability in aircraft components.

Furthermore, research indicates that the adoption of SiC heating elements is also beneficial in the ceramic industry, where they are used to achieve precise temperature control during the sintering process. This precision not only enhances product quality but also reduces cycle times. The increasing demand for advanced ceramics in industries like medical devices and electronics further underscores the importance of SiC as a leading heating solution, showcasing its versatility and efficiency across diverse applications.

Recent advancements in heating technologies are reshaping how industries approach efficiency and sustainability, particularly through innovations such as Silicon Carbide (SiC) heating elements. The global heating element market is projected to reach approximately $6.5 billion by 2026, with a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, driven in part by the push for more efficient and durable heating solutions. SiC heating elements are gaining traction due to their ability to operate at higher temperatures and voltages, which increases efficiency and enhances the lifespan of heating systems.

The future of heating technology is leaning towards smarter and more energy-efficient solutions. According to a report by Research and Markets, energy-efficient heating systems are expected to represent a significant portion of the market, with an increasing focus on materials that contribute to reduced energy consumption. SiC is at the forefront of this revolution, enabling faster heating and better thermal control, which are essential attributes for industries like semiconductor manufacturing and ceramics processing. By embracing SiC technology, companies not only ensure a reduction in operational costs but also align with global efforts toward environmental responsibility and energy conservation.