Leave Your Message

In the world of industrial applications, efficiency and reliability are key. The Silicon Carbide Heating Element stands out in these fields. Its unique properties make it an excellent choice for various heating tasks. Industries are increasingly turning to this material for high-temperature environments.

Silicon carbide is known for its durability. It can withstand extreme temperatures without failure. This is crucial for processes that demand consistent and reliable performance. Furthermore, these heating elements offer fast heating and cooling cycles, making them efficient. However, it’s important to consider the initial investment. While they boast lower operating costs over time, the upfront expense can be daunting.

Yet, not all situations may benefit from these elements. Sometimes, traditional heating solutions seem more practical. It's essential to weigh the pros and cons carefully. Ultimately, understanding the specific needs of your application is vital. The Silicon Carbide Heating Element might be the best fit, or perhaps not. Careful reflection will lead to the right choice.

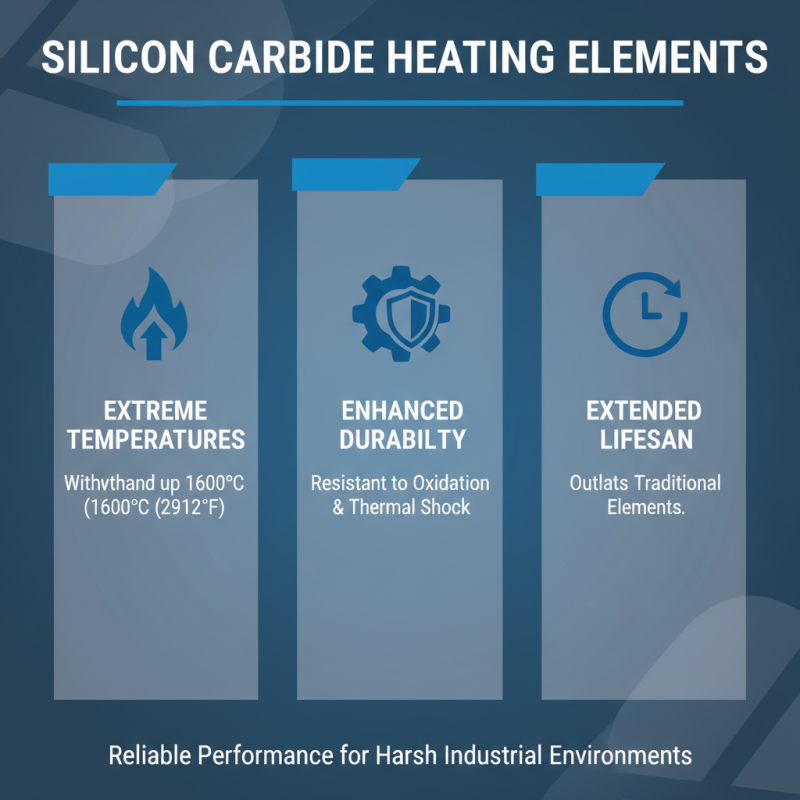

Silicon Carbide (SiC) heating elements have become increasingly popular in industrial settings for several reasons. One major benefit is their high thermal efficiency. According to industry data, SiC elements can achieve temperatures exceeding 1,600°C, far surpassing traditional heating materials. This means they can heat up quickly, reducing energy consumption over time. Businesses can save on operational costs by utilizing these efficient heating solutions.

Another advantage lies in their durability. SiC elements are resistant to oxidation and can withstand harsh environments. A study published by the American Ceramic Society highlighted that SiC components have a lifespan of over 50,000 hours under standard operational conditions. However, users must monitor their performance closely. Some reports indicate that prolonged exposure to certain chemicals can degrade their effectiveness.

Additionally, SiC heating elements offer great flexibility. They can be shaped and customized for various applications, whether in ceramics, metal processing, or semiconductor manufacturing. Yet, the initial installation cost can be a barrier for small enterprises. They need a careful evaluation of their long-term benefits versus initial investment. This trade-off requires thoughtful consideration before making the switch.

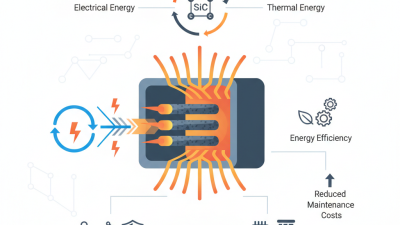

Silicon carbide (SiC) heating elements are making waves in various industrial applications. They offer significant advantages over traditional heating methods. For instance, SiC elements can operate at higher temperatures, often exceeding 1,600°C. This capability allows processes that require intense heat to be more efficient. According to recent industry reports, systems using SiC can achieve energy savings of up to 50%, a key factor for cost-conscious manufacturers.

Moreover, the thermal conductivity of silicon carbide is impressive. This material ensures consistent heat distribution. Unlike conventional materials, SiC minimizes hot spots and temperature fluctuations. An analysis from a leading materials research group indicates that SiC elements can also enhance process speeds by up to 30%. Many users note the reduced thermal cycles, extending equipment life.

However, there are challenges. Implementing SiC may require substantial upfront investment and adjustments to existing setups. Some companies may hesitate due to these costs. Still, the long-term savings in energy and maintenance make SiC a compelling choice for modern industrial heating needs. As industries evolve, reconsidering traditional heating methods may be essential for staying competitive.

Silicon carbide heating elements stand out for their durability and longevity in industrial applications. These materials can withstand extreme temperatures. They perform well in harsh environments, often exceeding the lifespan of traditional heating elements. The robust structure of silicon carbide resists oxidation and thermal shock, ensuring reliable performance.

In many manufacturing processes, downtime is costly. This is where the long-lasting nature of silicon carbide elements shines. They reduce the need for frequent replacements, minimizing disruption. However, one must consider installation and energy efficiency. Improper installation can lead to failures, which may negate their benefits. Understanding the specific needs of your application is crucial.

Beyond durability, silicon carbide heating elements maintain efficiency even over time. Their ability to reach high temperatures while consuming less energy contributes to cost savings. Still, it is essential to analyze compatibility with your systems. An ill-suited heating element can lead to inefficiencies. Regular monitoring and maintenance can help sustain their performance.

Silicon carbide (SiC) heating elements are gaining traction in various industrial applications due to their energy efficiency and cost-effectiveness. Research indicates that SiC solutions can exhibit up to 90% efficiency in thermal transfer, compared to traditional heating technologies that often operate below 70%. This significant difference translates into reduced energy costs and lower operational expenses over time.

Many industries are turning to SiC heating elements as they can withstand higher temperatures, which allows for better performance in demanding environments. For instance, they can operate at temperatures exceeding 1,600°C. This high thermal capacity reduces the need for frequent replacements, further enhancing cost-effectiveness. They also respond much faster to temperature adjustments, which results in less energy waste.

**Tip**: Regularly monitor the performance of SiC heating elements to ensure they operate within optimal parameters. A small change in efficiency can impact overall energy costs significantly.

Despite the benefits, some may find initial costs higher than traditional heating systems. It's essential to consider the long-term savings on energy bills and maintenance. A thorough analysis of your specific application requirements can clarify the potential return on investment.

**Tip**: Conduct a pilot test to compare energy consumption across different heating elements. Real-world data can provide valuable insights and guide better decisions.

| Dimension | Silicon Carbide Heating Elements | Traditional Heating Elements |

|---|---|---|

| Temperature Range (°C) | 600 - 1600 | 300 - 1200 |

| Energy Efficiency (%) | 95 | 80 |

| Operating Life (hours) | 40,000 | 10,000 |

| Typical Cost (per unit) | $150 | $100 |

| Corrosion Resistance | Excellent | Fair |

| Maintenance Needs | Low | High |

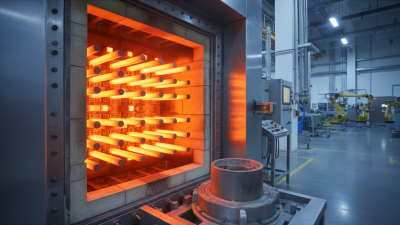

Silicon carbide heating elements are popular in various industrial applications. Their high thermal conductivity makes them ideal for environments requiring intense heat. You can find these elements in foundries, ceramics, and glass production. They operate effectively at high temperatures and offer excellent resistance to thermal shock. This durability is crucial for industries that need reliable equipment.

In the semiconductor industry, silicon carbide heating elements are essential. They help maintain precise temperatures in processes like doping and epitaxy. Additionally, they are used in the aerospace sector, where high-performance heating is vital. The automotive industry also benefits from these elements, particularly in electric vehicle production. Their efficiency can lead to cost savings and improved production rates.

However, not all applications may see flawless performance. In some cases, heating elements may wear out faster than expected. Frequent inspections can help catch these issues early. It’s essential to balance their initial cost against long-term benefits. Understanding how to manage these elements is key to maximizing efficiency.