Leave Your Message

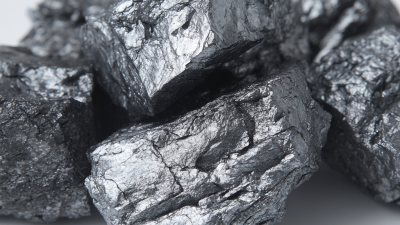

Silicon Manganese plays a crucial role in modern metallurgy, serving as a vital alloying element in the production of steel and other alloys. According to industry reports, the global silicon manganese market was valued at approximately $10.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 5.3% from 2023 to 2030. This growth is driven by the increasing demand for high-quality steel in various sectors, including construction, automotive, and manufacturing.

Silicon Manganese plays a crucial role in modern metallurgy, serving as a vital alloying element in the production of steel and other alloys. According to industry reports, the global silicon manganese market was valued at approximately $10.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 5.3% from 2023 to 2030. This growth is driven by the increasing demand for high-quality steel in various sectors, including construction, automotive, and manufacturing.

Silicon manganese acts not only as a deoxidizer but also enhances the strength, ductility, and overall performance of steel products. Furthermore, with the rise of sustainable practices in metallurgy, the use of silicon manganese allows for improved production efficiency and lower energy consumption, reinforcing its importance in the advancement of modern metalworking techniques. Understanding the nuances of silicon manganese thus becomes essential for industry stakeholders aiming to optimize their metallurgical processes and meet market demands.

Silicon manganese is an essential alloy in the steel production process, playing a critical role in enhancing the properties of steel while optimizing the manufacturing process. According to the International Stainless Steel Forum, the incorporation of silicon manganese can improve fluidity during melting, which leads to better castability and reduces the occurrence of defects in the latter stages of steel production. This is especially important in producing high-quality steel grades, where purity and uniformity are paramount.

Silicon manganese is an essential alloy in the steel production process, playing a critical role in enhancing the properties of steel while optimizing the manufacturing process. According to the International Stainless Steel Forum, the incorporation of silicon manganese can improve fluidity during melting, which leads to better castability and reduces the occurrence of defects in the latter stages of steel production. This is especially important in producing high-quality steel grades, where purity and uniformity are paramount.

Moreover, silicon manganese acts as a deoxidizer and a ferromanganese agent, helping to maintain the appropriate balance of carbon content in steel. Data from the World Steel Association indicates that approximately 30% of the global manganese demand is attributed to the steel industry, with silicon manganese contributing significantly to achieving desired strength and toughness in finished products.

By enhancing mechanical properties and reducing production times, silicon manganese not only aids in meeting stringent industry standards but also supports sustainability efforts by enabling lower energy consumption during steel manufacturing.

Silicon manganese alloys are becoming increasingly vital in modern metallurgy, particularly within the steelmaking sector. With the rapid growth of stainless steel production, the demand for ferroalloys, including silicon manganese, is projected to expand significantly. According to recent market reports, the ferroalloy market is expected to see substantial growth driven by the rising application in stainless steel, which often requires the incorporation of various alloying elements like silicon and manganese to enhance material properties.

Silicon manganese alloys are becoming increasingly vital in modern metallurgy, particularly within the steelmaking sector. With the rapid growth of stainless steel production, the demand for ferroalloys, including silicon manganese, is projected to expand significantly. According to recent market reports, the ferroalloy market is expected to see substantial growth driven by the rising application in stainless steel, which often requires the incorporation of various alloying elements like silicon and manganese to enhance material properties.

The key benefits of silicon manganese in metallurgy are its ability to improve hardness, tensile strength, and corrosion resistance. By incorporating these elements, steelmakers can produce materials that meet the stringent requirements of modern applications. Research indicates that the use of silicon manganese can lead to improved deoxidation processes and enhanced weldability, making it an essential additive for producing high-quality steel products.

Tips: When selecting alloys for specific applications, consider the balance of elements in the alloy. Silicon manganese not only contributes to the strength of steel but also assists in achieving better stability during the manufacturing process. Regularly review market trends to stay informed about the best practices in alloy selection, as the industry's dynamics can impact material availability and pricing.

Silicon manganese is a vital alloy in modern metallurgy, particularly in the production of high-strength steel. Its unique properties enhance the overall performance of steel, making it an essential ingredient for various industrial applications. When compared to other alloys, such as ferrosilicon and ferromanganese, silicon manganese presents a more favorable balance of strength, ductility, and oxidation resistance. This comparative advantage is crucial in industries where material durability and reliability are paramount, such as construction, automotive, and aerospace.

The synergy of silicon and manganese in this alloy not only improves deoxidation processes but also influences the formation of inclusions, which can be detrimental in steel production. While ferrosilicon is effective in refining and deoxidizing, it lacks the strength-enhancing properties provided by manganese. On the other hand, ferromanganese contributes to the steel’s toughness but may require higher carbon content, resulting in a varied performance profile. Therefore, silicon manganese emerges as the optimal choice for producing steel that withstands rigorous demands, highlighting the importance of this alloy in the evolution of modern metallurgy.

| Alloy Type | Main Composition | Primary Applications | Benefits | Challenges |

|---|---|---|---|---|

| Silicon Manganese | Silicon (14-18%), Manganese (60-68%) | Steel production, Alloying agent | Improved strength and ductility | Price volatility, Environmental regulations |

| Low Alloy Steel | Carbon, Manganese, Nickel | Construction, Automotive | Good weldability, Cost-effective | Lower corrosion resistance |

| Stainless Steel | Chromium, Nickel, Manganese | Kitchenware, Medical instruments | Corrosion resistance, Aesthetic appeal | High cost, Difficulty in welding |

| High Carbon Steel | Carbon (0.60-1.00%), Manganese | Tools, Machinery | High hardness, Wear resistance | Brittleness, Limited ductility |

Silicon manganese is a crucial alloy in modern metallurgy, playing an essential role across various industries. In steel production, silicon manganese serves as a deoxidizing and alloying agent, enhancing the mechanical properties of steel. Its addition improves tensile strength, ductility, and overall toughness, making it particularly valuable in the manufacturing of high-strength steel used in construction and automotive applications. The improved resistance to oxidation and heat also makes silicon manganese vital for producing components that can withstand harsh environments, such as gears and shafts.

In the production of ferroalloys, silicon manganese is employed to improve the quality and performance of various metals. The alloy is widely utilized in the aluminum and copper industries, where it aids in refining processes and enhances electrical conductivity. Additionally, silicon manganese finds applications in the production of cast iron, where it contributes to the formation of specific microstructures that improve wear resistance and reduce brittleness. Its versatility across multiple sectors highlights the importance of silicon manganese in achieving better performance, cost efficiency, and product quality in modern metallurgy.

Silicon manganese is a crucial alloy in modern metallurgy, primarily valued for its role in steel production. However, its environmental impact and sustainability are increasingly coming under scrutiny as industries seek greener alternatives. The production of silicon manganese can generate significant carbon emissions, which contribute to climate change. Therefore, understanding and mitigating the environmental footprint of this alloy is essential for the steel manufacturing sector to achieve its sustainability goals.

To address these concerns, innovative methods are being explored to reduce emissions associated with silicon manganese production. For instance, utilizing renewable energy sources in the smelting process can significantly lower the carbon output. Furthermore, recycling silicon manganese scrap and optimizing the alloying process can lead to more efficient resource use, minimizing waste and promoting a circular economy. By prioritizing sustainable practices in silicon manganese production and application, the metallurgy industry can align with global sustainability initiatives while maintaining the quality and performance of steel.

This chart presents a comparative analysis of various important factors related to Silicon Manganese in modern metallurgy, including production volume, scrap steel utilization, environmental impact, and carbon emission reduction percentage. It highlights the significance of Silicon Manganese in promoting sustainability within the metallurgical industry.