Leave Your Message

Choosing the right Silicon Carbide Rod for your project can significantly impact the efficiency and effectiveness of your applications. Silicon carbide, known for its remarkable hardness and high thermal conductivity, is an essential material across various industries, ranging from electrical engineering to manufacturing. Selecting the appropriate rod involves understanding the specific requirements of your project, including temperature resistance, electrical characteristics, and mechanical strength.

In this guide, we will explore key considerations that will help you make an informed decision when selecting a Silicon Carbide Rod. By evaluating the material's properties, understanding the different manufacturing processes, and recognizing the specific needs of your application, you can ensure optimal performance and longevity in your project. Whether you are engaged in high-temperature applications or require exceptional abrasive resistance, these essential tips will guide you through the selection process, ensuring you achieve your project's goals with the right materials.

When selecting silicon carbide rods for industrial applications, it is crucial to consider several essential factors to ensure optimal performance and efficiency. Silicon carbide rods are widely recognized for their superior thermal conductivity and chemical resistance, making them ideal for high-temperature environments. According to a report by Grand View Research, the silicon carbide market is expected to reach $7.4 billion by 2025, indicating a growing demand for this material in various sectors, including automotive and electronics.

One of the primary tips when choosing silicon carbide rods is to analyze the specific application requirements. The operational environment—such as temperature range, exposure to corrosive substances, and mechanical load—plays a pivotal role in material selection. For instance, rods designed for high thermal shock resistance are essential in applications such as kilns or furnaces, where abrupt temperature changes can occur. Industry standards, such as ASTM C865, provide guidelines on the mechanical properties and performance criteria relevant to silicon carbide products.

Another crucial factor to consider is the rod dimensions and form. Depending on the project’s specifications, selecting the correct rod diameter and length can significantly affect performance. Customization options are often available, catering to various industrial needs. The right configuration not only contributes to efficiency but also minimizes waste and optimizes production processes. Therefore, engaging with materials specialists or utilizing detailed specification sheets can help in making informed decisions based on the unique requirements of your application.

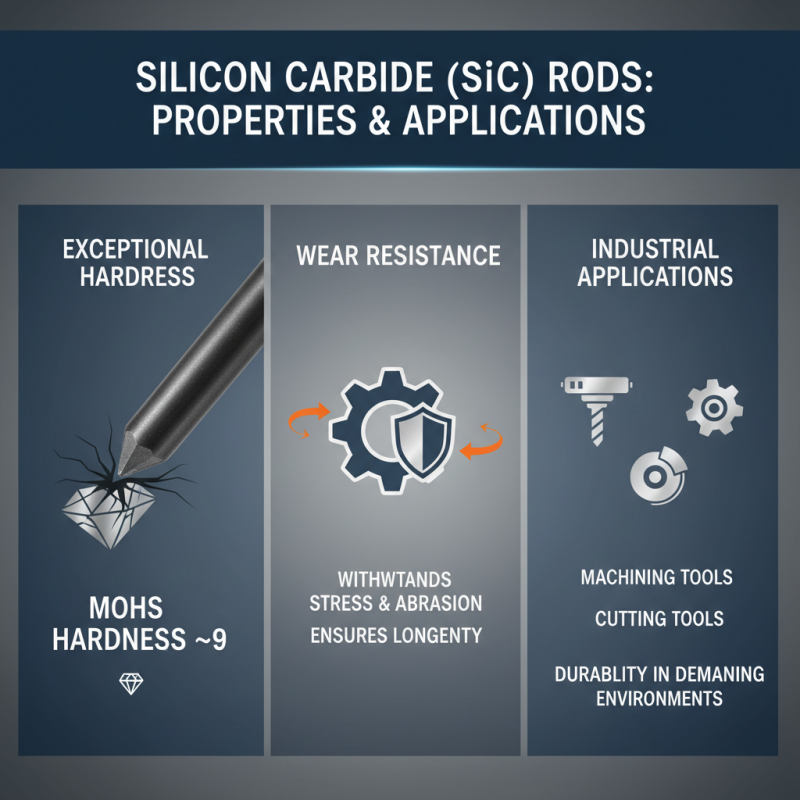

When selecting the right silicon carbide (SiC) rod for your application, understanding its properties is key. Silicon carbide is renowned for its exceptional hardness, making it an ideal material in applications where wear resistance is crucial. With a hardness rating of around 9 on the Mohs scale, SiC rods can withstand significant stress and abrasion, ensuring longevity even in demanding environments. This property is particularly beneficial in industrial applications, such as machining or cutting tools, where durability is paramount.

In addition to hardness, thermal conductivity is another vital characteristic of silicon carbide. SiC exhibits remarkable thermal conductivity, enabling efficient heat transfer while maintaining structural integrity at high temperatures. This quality is especially important in semiconductor applications or high-temperature processes, where temperature management is essential for optimal performance and safety. By recognizing these properties, you can make a more informed decision when choosing a silicon carbide rod, ensuring it aligns with the specific needs of your project.

When evaluating the application of silicon carbide (SiC) rods versus traditional materials, it’s crucial to consider how these two differ in terms of thermal conductivity, durability, and overall performance. Recent industry reports indicate that silicon carbide possesses a thermal conductivity of around 120-150 W/m·K, which significantly outperforms aluminum and even some copper alloys. This superior conductivity allows for better heat dissipation in high-temperature applications, making SiC rods an ideal choice for industries like aerospace and automotive.

When selecting the right silicon carbide rod for your specific project, consider the application’s temperature requirements. SiC rods can withstand temperatures exceeding 1,600°C, while typical traditional materials like stainless steel tend to reach their limit at around 800°C. This dramatic difference allows engineers more flexibility in design and material choice, ultimately boosting performance and longevity.

Tip: Always analyze your project’s requirements before making a choice. If high thermal stability is a priority, silicon carbide is the superior option. Additionally, assess the environmental factors your materials will encounter; SiC’s resistance to oxidation and chemical corrosion can drastically improve longevity in harsh conditions. By considering these elements, you can make a more informed decision that aligns with your project goals.

When planning a long-term project, especially in fields like manufacturing or construction, it’s essential to consider the cost-effectiveness of the materials you choose. Silicon carbide rods have emerged as a popular option, primarily due to their durability and efficiency. While the initial investment may be higher than other materials, their longevity and performance can lead to significant savings over time. Instead of frequent replacements, investing in silicon carbide rods means less downtime and fewer interruptions, which is crucial for maintaining project timelines and budgets.

When selecting the right silicon carbide rod for your project, ensure you evaluate the specific requirements of your application. One tip is to consider the operating temperatures and the mechanical stresses the rod will endure. Different grades and sizes of silicon carbide rods are available, and matching these to your project’s demands can enhance performance. Additionally, it may be beneficial to consult with experts in the field to understand the best options and configurations available for your unique needs.

Another important tip is to factor in the overall lifecycle cost of the rod. While the upfront cost is significant, assessing the performance characteristics, including wear resistance and thermal stability, will give you a clearer picture of the long-term value. This holistic approach ensures that you are not only looking at initial expenditures but also the overall benefits that silicon carbide rods bring to your project over time.

| Attribute | Description | Cost-Effectiveness |

|---|---|---|

| Material Composition | Mainly composed of silicon and carbon, offering high thermal conductivity and low thermal expansion. | High durability reduces replacement costs. |

| Temperature Rating | Suitable for high-temperature applications up to 1600°C. | Minimizes expense on multiple rod types for varied temperatures. |

| Resistance to Oxidation | Good performance in oxidizing environments, extending lifespan. | Lower long-term maintenance costs due to reduced oxidation-related failures. |

| Electrical Conductivity | Excellent electrical properties, making it suitable for semiconductor applications. | Cost effective when integrated into electronic components, reducing overall project costs. |

| Availability | Widely available in various sizes and shapes for different applications. | Consistent supply reduces downtime and project delays, saving costs. |

Silicon carbide rods have gained immense popularity across various industries due to their exceptional mechanical and thermal properties. These rods are commonly used in the manufacturing of kiln furniture, where they provide support during high-temperature processes, ensuring durability and resistance to thermal shock. In the aerospace sector, silicon carbide rods are utilized in components where lightweight strength is critical, such as in heat shields and rocket nozzles, aiding in performance despite the rigors of extreme temperatures and pressures.

In the field of electronics, silicon carbide rods play a vital role in semiconductor applications. Their ability to operate at high voltages and temperatures makes them ideal for power devices and high-frequency applications. Additionally, the automotive industry has begun to adopt silicon carbide technologies, particularly in electric vehicle (EV) batteries and charging systems, where efficiency and compactness are essential. This material's versatility demonstrates its significance across multiple domains, solidifying silicon carbide rods as a fundamental component in modern technological advancements.