Leave Your Message

Ferro Silicon Magnesium (FeSiMg) is a critical alloy in the iron and steel industry, known for its powerful role as a nodulizing agent in the production of ductile iron. According to industry reports, the global market for Ferro Silicon Magnesium has been experiencing robust growth, fueled by the increasing demand for high-performance materials in automotive, construction, and machinery applications. In fact, the Ferro Silicon Magnesium market is projected to expand at a CAGR of approximately 4.5% from 2021 to 2026, underscoring its significance in advancing metallurgical processes. The alloy not only enhances the mechanical properties of cast iron but also plays a vital role in reducing production costs and improving the environmental footprint of metallurgical operations. This blog aims to provide an in-depth understanding of Ferro Silicon Magnesium, exploring its applications, benefits, and the transformative impact it has on various industries.

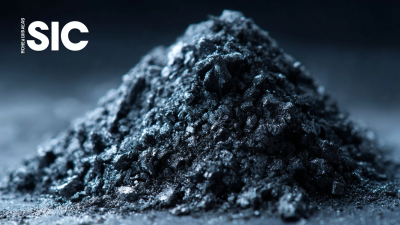

Ferro silicon magnesium (FeSiMg) is a unique alloy primarily composed of iron, silicon, and magnesium, known for its crucial role in the production of ductile iron. The chemical properties of FeSiMg make it an essential material in various metallurgical applications. With typically 60-70% silicon, 1-2% magnesium, and a balance of iron, the alloy enhances the mechanical properties of cast iron by improving fluidity, lowering melting temperatures, and significantly influencing the microstructure.

Recent reports indicate that the global demand for FeSiMg is projected to reach 2 million tons by 2025, growing at a CAGR of 5.5% from 2020. This uptick is largely driven by the automotive and construction industries, which increasingly rely on the alloy for its ability to enhance impact strength and tensile properties. The addition of magnesium promotes the formation of a spheroidal graphite structure in cast iron, which contributes to the superior performance of components used in critical applications, from engine blocks to pipelines. Understanding the composition and advantages of ferro silicon magnesium is key for industries aiming to optimize their material performance and reduce production costs.

Ferro Silicon Magnesium (FeSiMg) plays a crucial role in the production of ductile iron, a material renowned for its excellent mechanical properties and versatility. This alloying element enhances the ductility of iron by promoting the formation of spheroidal graphite during the casting process. The resulting iron has superior strength, shock resistance, and wear resistance, making it an optimal choice for various applications including automotive, machinery, and construction.

Tips for using Ferro Silicon Magnesium effectively in ductile iron production include monitoring the composition carefully. Maintaining the right balance of silicon and magnesium is essential to ensure the desired properties of the final product. Additionally, consider the melting temperature and the pouring temperature during casting; managing these can significantly influence the quality of the ductile iron.

Another tip is to conduct regular assessments of the material’s microstructure. This will help in identifying potential defects early on, such as the formation of undesirable graphite shapes. By closely managing the manufacturing conditions and using proper testing methods, manufacturers can optimize the benefits of Ferro Silicon Magnesium, leading to improved performance of ductile iron products.

Ferro Silicon Magnesium (FeSiMg) plays a crucial role in metallurgical processes, particularly in the production of ductile iron. One of the primary economic benefits of utilizing FeSiMg is its ability to enhance the mechanical properties of castings. By improving tensile strength and ductility, manufacturers can produce lighter components that require fewer raw materials, thus reducing costs. Additionally, the increased durability of ductile iron parts leads to lower maintenance expenses and a longer service life, creating significant savings over time.

Another economic advantage of using Ferro Silicon Magnesium is its positive impact on production efficiency. The addition of FeSiMg simplifies the alloying process and facilitates better control over molten iron chemistry. This results in lower energy consumption during production and minimizes the occurrence of defects in castings, which can lead to costly rework or scrapping. By streamlining operations and reducing waste, manufacturers can achieve higher output rates and improve overall profitability, making FeSiMg an attractive investment for metal producers looking to optimize their processes.

| Application | Benefit | Economic Impact | Usage Rate (%) |

|---|---|---|---|

| Ductile Iron Casting | Improved ductility and toughness | Higher strength-to-weight ratio | 45% |

| Steel Production | Improved fluidity for casting | Reduced material waste | 35% |

| Alloy Manufacturing | Enhanced alloy properties | Higher quality end products | 60% |

| Foundry Applications | Better casting outcome | Decrease in rework costs | 55% |

| Metalworking | Increased wear resistance | Lower maintenance costs | 50% |

Ferro Silicon Magnesium (FeSiMg) has gained prominence in the metallurgy industry, particularly in ductile iron production. When compared to other alloying elements like silicon, manganese, and nickel, FeSiMg stands out due to its unique properties. Silicon contributes to deoxidation and gives fluidity; however, it does not enhance tensile strength as effectively as Ferro Silicon Magnesium does. On the other hand, manganese is critical for improving toughness but can introduce issues related to hardenability.

One significant advantage of FeSiMg is its ability to promote higher nodularity in cast iron, leading to improved mechanical properties. Compared to nickel, which can be more costly and introduce brittleness at certain levels, FeSiMg provides a more economical and balanced approach. Its effect on the cast microstructure helps achieve a finer grain size and enhances wear resistance, making it a preferable choice for various industrial applications. Ultimately, while each alloying element has its merits, Ferro Silicon Magnesium offers a unique combination of affordability, performance, and versatility that makes it an essential component in modern metallurgical practices.

The future trends surrounding Ferro Silicon Magnesium (FeSiMg) applications indicate a significant alignment with the global push towards sustainable and high-performance materials. As industries increasingly prioritize environmental responsibility and efficiency, the demand for Ferro Silicon Magnesium is expected to rise. Its unique properties not only enhance the performance of magnesium alloys used in various sectors—ranging from automotive to aerospace—but also contribute to the development of greener technologies. The integration of FeSiMg into advanced manufacturing processes is set to redefine material standards, meeting both economic and ecological goals.

Moreover, innovations in the application of Ferro Silicon Magnesium are likely to correlate with the evolving landscape of sensor technology, as illustrated by recent developments in the sensor industry. Events like the 2025 Shenzhen International Sensor and Application Technology Exhibition highlight the intersection of diverse technologies and materials. The adaptability of Ferro Silicon Magnesium in sensor applications will play a crucial role in shaping smart technologies, thereby driving market demand forward. As these innovations unfold, they pave the way for a deeper understanding of FeSiMg's potential, ensuring that it remains at the forefront of industry advancements.