Leave Your Message

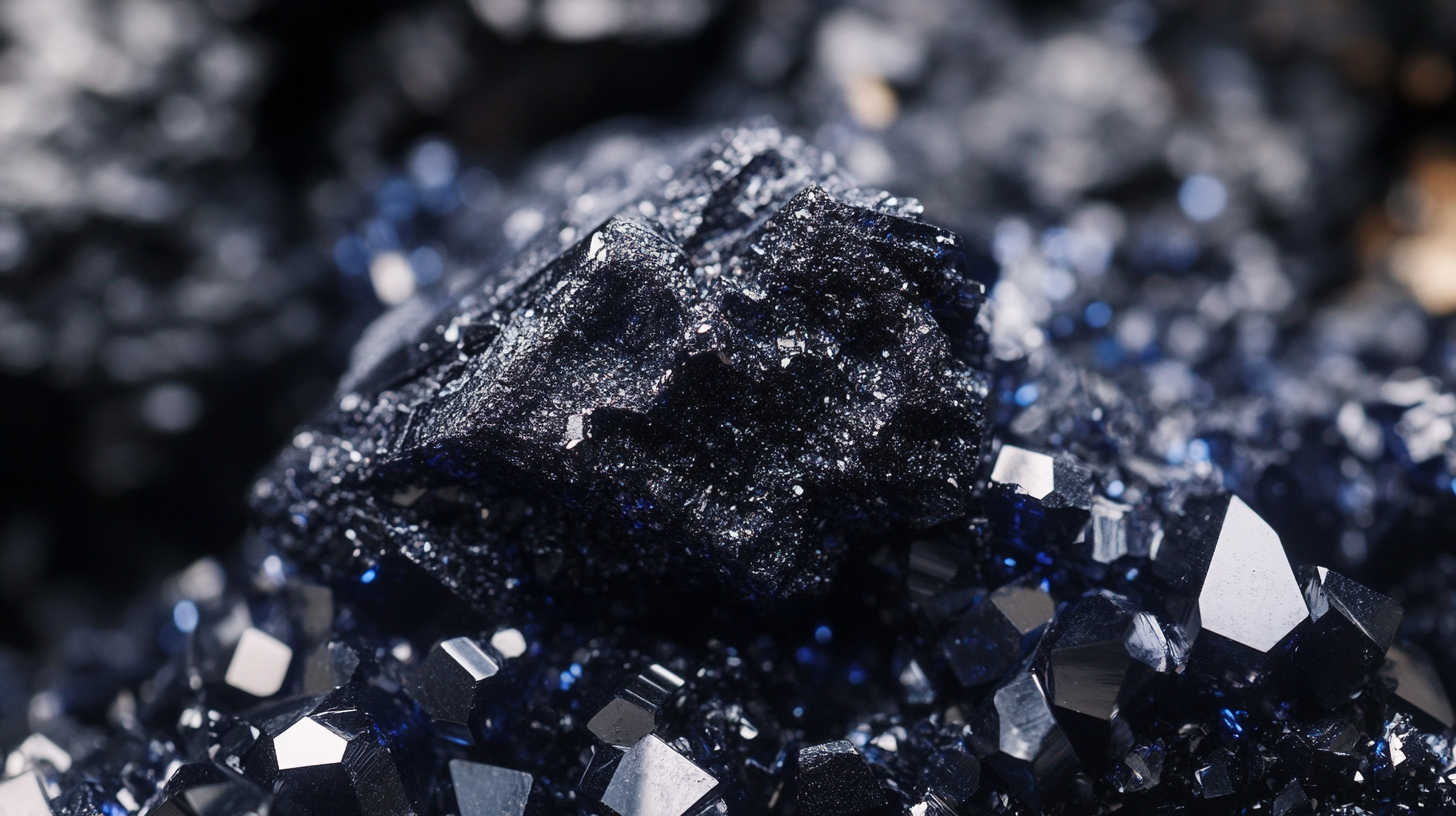

In the ever-evolving landscape of industrial materials, Black Silicon Carbide stands out as a premier choice, offering unmatched durability and performance that significantly enhances manufacturing processes worldwide. According to a recent report by Mordor Intelligence, the global silicon carbide market is projected to grow at a CAGR of over 16% from 2021 to 2026, driven by increasing demand across various sectors including automotive, electronics, and aerospace. This surge underscores the importance of harnessing high-quality materials like Black Silicon Carbide, which not only improves product efficiency but also fosters sustainable practices in manufacturing. As China positions itself as a leading global manufacturing partner, leveraging the unique benefits of best Black Silicon Carbide can unlock new avenues for exceptional quality and value in sourcing strategies.

The rise of black silicon carbide (SiC) in global sourcing markets has marked a significant shift in the materials landscape. Known for its exceptional hardness and thermal conductivity, black silicon carbide is increasingly being favored in various industries, including electronics, abrasives, and automotive manufacturing. Its unique properties, such as high corrosion resistance and durability, make it an attractive option for companies seeking reliable materials that enhance performance and reduce operational costs.

As global demand for advanced materials continues to grow, the sourcing of black silicon carbide has become more strategic. Suppliers are now focusing on high-quality production processes that ensure consistency and uniformity in the material’s properties. This not only meets the stringent requirements of modern applications but also positions companies to leverage the benefits of black silicon carbide more effectively.

As manufacturers and businesses worldwide recognize these advantages, the market for black silicon carbide is expected to expand, driving innovation and competitiveness across various sectors.

Black Silicon Carbide (SiC) has emerged as a superior alternative to traditional materials like silicon and sapphire, especially in various high-performance applications. Unlike conventional options, SiC boasts excellent thermal conductivity, high voltage breakdown capability, and superior efficiency, making it highly suitable for power electronics and semiconductor devices. The impressive properties of Black SiC enable it to perform effectively in extreme conditions, thereby extending the lifespan of components and reducing overall operational costs.

**Tips for Sourcing Black Silicon Carbide:**

When considering the switch to Black Silicon Carbide, it's essential to assess the reliability of your suppliers. Look for manufacturers with a proven track record in the industry, as consistent quality is crucial for optimal performance. Additionally, evaluate the cost vs. benefit ratio; while Black SiC may present a higher upfront cost, the long-term savings from improved efficiency and durability can be significant.

Moreover, ensure that any Black SiC products you source come with comprehensive performance data. Understanding how Black SiC compares to traditional materials in the context of your specific applications will allow you to make well-informed decisions that can enhance your product offerings and market position.

Black silicon carbide (SiC), a key player in the realm of industrial applications, stands out due to its unique properties and versatility. Known for its high hardness and thermal conductivity, black SiC is extensively used in abrasive materials, cutting tools, and advanced ceramics. According to a recent report by MarketsandMarkets, the global silicon carbide market is projected to reach USD 6.5 billion by 2025, driven by rising demand in aerospace, automotive, and electronics industries. This growth is a testament to the material’s strength and performance characteristics that make it indispensable across multiple sectors.

Moreover, the unique benefits of black SiC extend to its environmental resistance, making it suitable for high-temperature applications. Its ability to withstand extreme conditions without degrading ensures operational reliability in challenging environments. This durability is highlighted in a study from Research and Markets, which suggests that over 60% of manufacturers are shifting towards silicon carbide solutions to improve efficiency while minimizing resource consumption.

The production process of black silicon carbide (SiC) involves several key stages that contribute to its exceptional properties, making it a premier choice for various applications in global sourcing. Initially, the process begins with the mixing of high-purity silica sand and carbon in an electric arc furnace. As the mixture is subjected to intense heat, typically around 1,600 to 2,500 degrees Celsius, a chemical reaction takes place, resulting in the formation of silicon carbide crystals.

Following the formation, the SiC is cooled and then crushed to achieve desired grain sizes. The black color of this carbide, distinguishing it from its green counterpart, arises from the impurities present during synthesis. It is this unique coloration that enhances its thermal and mechanical stability, making it ideal for harsh environments.

The final stages involve precise grading and quality control to ensure that manufacturers receive a product that meets stringent industry standards. As black silicon carbide continues to gain global traction, understanding its production process sheds light on its unique advantages and applications in sectors from aerospace to electronics.

Black silicon carbide (SiC) is emerging as a pivotal material in the drive towards sustainability, particularly in light of its various applications that align with environmental goals. As industries strive for greener practices, the use of black SiC in manufacturing processes reduces reliance on synthetic materials and minimizes waste. Studies suggest that SiC has a significantly lower production footprint compared to traditional alternatives, making it an attractive choice for companies committed to reducing their carbon emissions. The lifecycle assessment of materials indicates that SiC can contribute to energy efficiency, further enhancing its sustainability profile.

Moreover, the integration of black silicon carbide into power electronics is particularly noteworthy. These components are essential for smart grid technologies, enabling efficient energy conversion and promoting renewable energy integration. Recent reports indicate that the adoption of SiC-based devices can lead to a reduction in energy losses of up to 30% compared to conventional technologies. This eco-friendly transition not only supports the global shift towards sustainable energy solutions but also highlights the vital role of innovative materials in combating climate change. As companies increasingly prioritize ESG (Environmental, Social, and Governance) criteria, the demand for high-performance materials like black silicon carbide will likely continue to grow.