Leave Your Message

Green Silicon Carbide (SiC) has gained prominence in various industries due to its exceptional hardness and thermal conductivity. Reports indicate that the global SiC market is expected to reach $4.5 billion by 2026, with a significant focus on green variants. This material is particularly valued in electronics and abrasive applications.

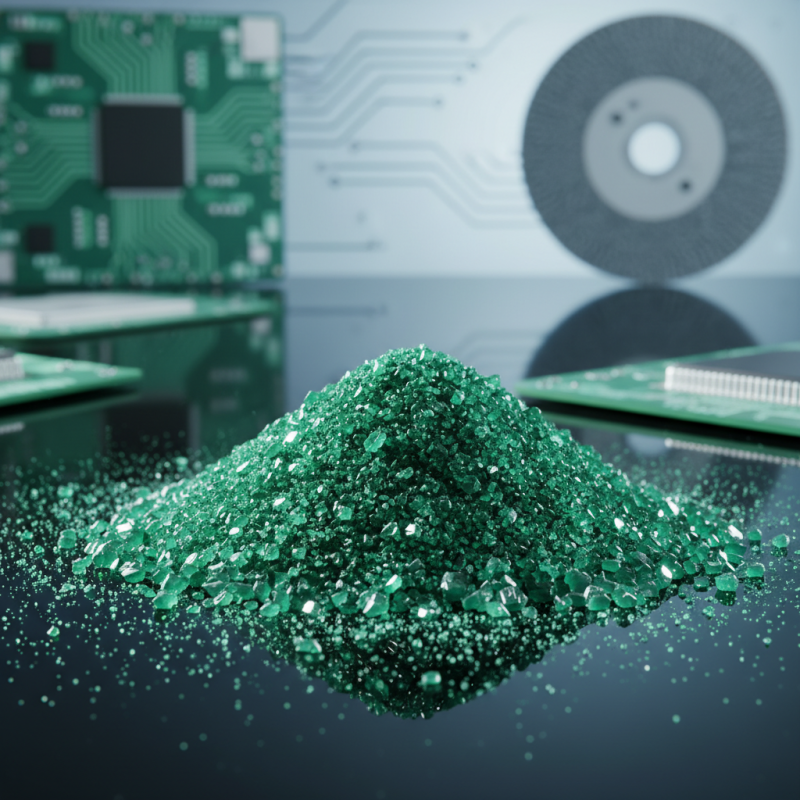

However, achieving optimal performance with Green Silicon Carbide requires careful consideration of several factors. The grain size and purity levels are critical. Small variations can drastically alter performance outcomes. Research has shown that the right grain size can improve machining efficiency by over 20%.

Despite its advantages, challenges remain. The cost of high-purity Green Silicon Carbide can be a hurdle for some manufacturers. Additionally, its brittleness can lead to unexpected failures in demanding applications. Understanding these nuances is essential for maximizing the benefits of this powerful material.

Green silicon carbide is an essential material known for its unique properties. It exhibits excellent hardness and high thermal conductivity. These traits make it perfect for various industrial applications, including abrasives and refractory materials. You’ll often find it used in grinding wheels and cutting tools. Its durability ensures long-lasting performance in demanding environments.

In terms of applications, green silicon carbide proves crucial in different industries. The semiconductor sector utilizes it for its electrical conductivity. In the manufacturing of ceramics, it enhances strength and thermal stability. However, it’s important to note that not all applications benefit equally from this material. Some industries may struggle to operate efficiently with green silicon carbide. This calls for deep understanding and consideration before implementation.

Many users face challenges while utilizing this material. Its processing can be tricky and might require special techniques. Industries need to ensure they match green silicon carbide with appropriate tools. This can lead to better outcomes in their projects. Sometimes, experimentation is necessary to find the perfect fit, creating a crucial learning experience.

Choosing the right grade of green silicon carbide can greatly affect performance and efficiency. Green silicon carbide is available in various grades, each suited for different applications. For example, the F120 to F240 grades are ideal for fine grinding, while the F80 to F100 grades work better for coarse applications. Selecting the right grade ensures better surface finish and longer tool life.

When considering your needs, assess the hardness and grain size of the material you’ll be working with. The Mohs hardness of green silicon carbide is around 9.25, making it nearly as hard as diamond. Higher grades produce finer particles, which improve surface quality, but they may also cost more. In some cases, a coarse grade may be more effective than a finer one, depending on the task at hand.

**Tip:** Always conduct a small test with a new grade to find the best fit for your application. You might discover that a different grade performs better than expected.

It’s essential to reflect on your specific needs and possible oversights. Sometimes, users stick to a familiar grade out of habit, missing better options. Keep an open mind, and be ready to experiment with different grades to optimize performance.

Green silicon carbide is widely used in various industries due to its unique properties. To utilize it effectively, proper techniques are essential. This material excels in applications like grinding, polishing, and even in ceramic production. Its hardness and thermal conductivity enable efficient performance during these tasks.

When using green silicon carbide, it's important to choose the right grit size. Coarser grits can remove material quickly but may leave a rough surface. Finer grits provide a smoother finish but can slow down the process. Reflecting on the correct balance is crucial. Experimenting to find the ideal combination for specific materials can significantly impact results.

Maintaining appropriate pressure and speed during operations is another key factor. Too much pressure can lead to excessive heat, damaging both the workpiece and the silicon carbide tool. A lower speed may improve control but could increase time per task. Each experience reveals new insights, prompting adjustments along the way. Recognizing the nuances of these variables can enhance overall efficiency and performance in industrial applications.

When handling green silicon carbide, safety comes first. Always wear protective gear. This includes gloves, goggles, and a mask. Dust from silicon carbide can be harmful if inhaled. Be particularly careful in enclosed spaces. Ensure good ventilation to minimize dust accumulation.

Proper storage is essential. Keep green silicon carbide in a dry, cool area. Avoid moisture to prevent clumping. Sealed containers are ideal. Accidentally mixing with incompatible materials can create risks, so label containers clearly. Regularly check for deterioration signs.

Disposing of green silicon carbide requires attention. Follow local regulations for hazardous materials. Throwing it away without care can lead to environmental issues. Even small amounts can impact nature. Reflecting on these details ensures a safer work environment. Proper handling is crucial to achieve optimal performance while minimizing risks.

Proper maintenance and storage of green silicon carbide can significantly extend its performance life. Regularly inspecting the abrasive grains for wear and tear is crucial. A study by the Abrasives Manufacturers Association indicates that maintained abrasives can retain up to 90% of their effectiveness over prolonged use. In contrast, neglecting to check for contamination or damage may result in diminished performance.

Storage conditions matter too. Green silicon carbide should be kept in a cool, dry area. A humidity level below 50% is ideal. The presence of moisture can lead to clumping and reduced efficacy. Also, keeping these materials away from direct sunlight can prevent physical degradation. Some experts recommend using airtight containers to protect against environmental factors.

It’s easy to overlook minor details. For instance, using the wrong type of protective gear while handling silicon carbide can lead to health risks. Proper personal protective equipment (PPE) is essential. Additionally, improper disposal of contaminated abrasives can harm the environment. Reflecting on these factors may lead to better practices in the workplace, ensuring that the benefits of green silicon carbide are fully realized.

| Dimension | Optimal Value | Maintenance Practice | Storage Recommendation |

|---|---|---|---|

| Grain Size | 60 - 120 mesh | Regularly check for clogs | Store in a cool, dry place |

| Purity Level | 97% or higher | Inspect for contamination | Seal in airtight containers |

| Temperature Limit | Up to 1,600°C | Monitor operational temperatures | Avoid exposure to extreme temperatures |

| Hardness | 9.25 on Mohs scale | Regular inspections for wear | Keep away from soft materials |

| Dust Control | Low dust production | Use appropriate PPE during grinding | Store in ventilated areas |